Method for rapidly preparing high-performance SiGe high-temperature thermoelectric alloy material

An alloy material and high-performance technology, which is applied in the field of rapid preparation of high-performance SiGe high-temperature thermoelectric alloy materials, can solve the problems of easy introduction of other impurities, high energy consumption of the preparation process, and expensive raw materials, and achieve high efficiency and energy saving, simple process, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

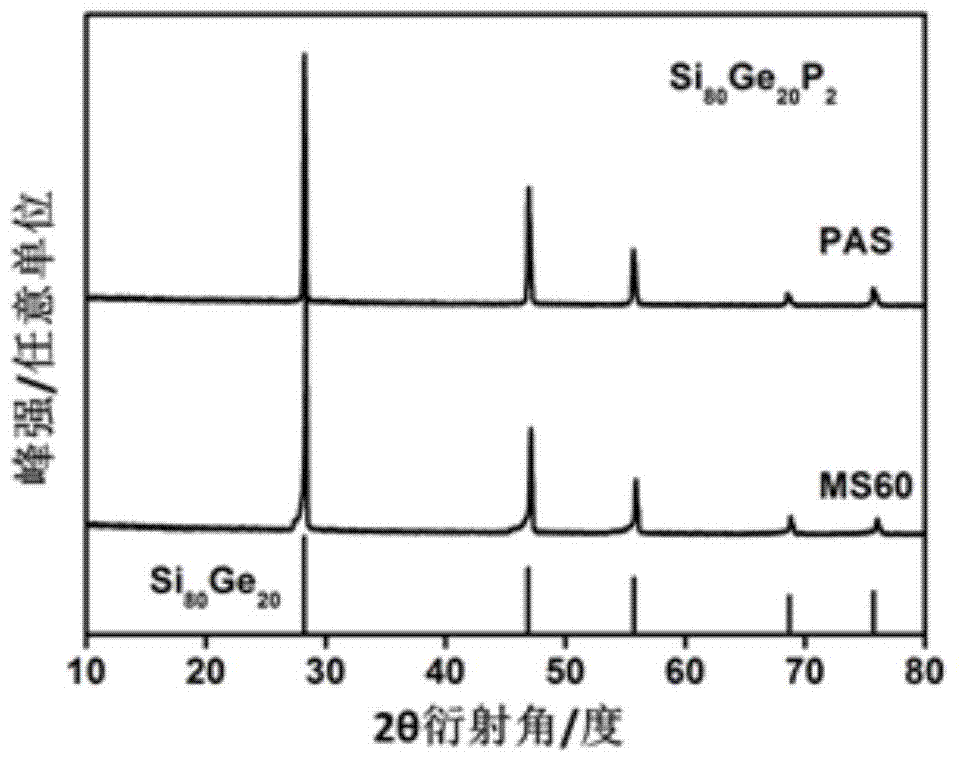

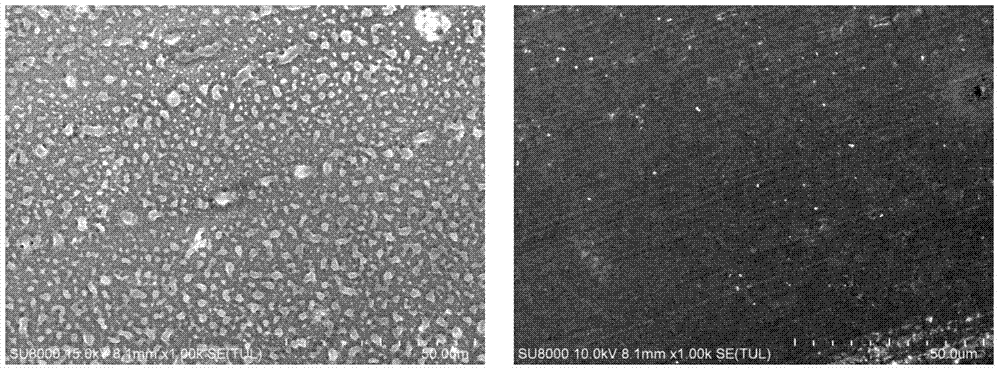

[0036] A method for rapidly preparing SiGe high-temperature thermoelectric alloy materials, comprising the following steps:

[0037] 1) Press Si 80 Ge 20 P 2 The stoichiometric ratio of each atom is weighed. Weigh 2.2468g of Si simple mass, 1.4526g of Ge simple mass, 0.0619g of red phosphorus, the mass purity of simple Si mass ≥99.999%, the mass purity of single Ge mass ≥99.99%, granular red The mass purity of phosphorus is ≥99.999%, and then the weighed raw materials are vacuum-sealed in a glass tube;

[0038] 2) Place the glass tube filled with raw materials in step 1) in a high-frequency induction melting furnace, and evacuate to a temperature lower than 10 -2 Pa, and then filled with argon until the cavity pressure is -0.05MPa, and then applied a voltage of 380V for high-frequency induction melting, the corresponding current is 12A, and the melting process lasts for 3 minutes;

[0039] 3) Place the ingot body obtained in step 2) in a graphite crucible with a nozzle len...

Embodiment 2

[0044] A method for rapidly preparing SiGe high-temperature thermoelectric alloy materials, comprising the following steps:

[0045] 1) Press Si 80 Ge 20 P 2 The stoichiometric ratio of each atom is weighed. Weigh 2.2468g of Si simple mass, 1.4526g of Ge simple mass, 0.0619g of red phosphorus, the mass purity of simple Si mass ≥99.999%, the mass purity of single Ge mass ≥99.99%, granular red The mass purity of phosphorus is ≥99.999%, and then the weighed raw materials are vacuum-sealed in a glass tube;

[0046] 2) Place the glass tube filled with raw materials in step 1) in a high-frequency induction melting furnace, and evacuate to a temperature lower than 10 -2 Pa, and then filled with argon until the cavity pressure is -0.05MPa, and then applied a voltage of 380V for high-frequency induction melting, the corresponding current is 12A, and the melting process lasts for 3 minutes;

[0047] 3) Place the ingot body obtained in step 2) in a graphite crucible with a nozzle len...

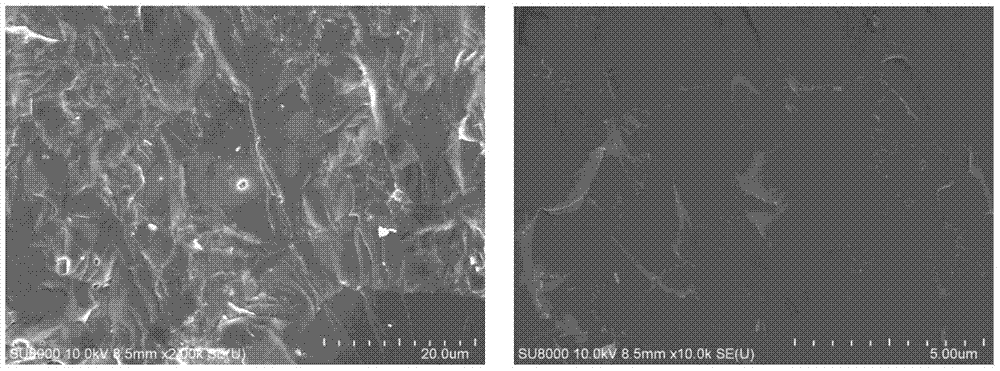

Embodiment 3

[0052] A method for rapidly preparing SiGe high-temperature thermoelectric alloy materials, comprising the following steps:

[0053] 1) Press Si 80 Ge 20 P 10 The stoichiometric ratio of each atom is weighed, and 2.2468g of Si single mass block, 1.4526g of Ge single mass block, 0.3095g of red phosphorus are weighed, the mass purity of simple mass Si block is ≥99.999%, the mass purity of single mass Ge block is ≥99.99%, and granular red The mass purity of phosphorus is ≥99.999%, and then the weighed raw materials are vacuum-sealed in a glass tube;

[0054] 2) Place the glass tube filled with raw materials in step 1) in a high-frequency induction melting furnace, and evacuate to a temperature lower than 10 -2 Pa, and then filled with argon until the cavity pressure is -0.05MPa, and then applied a voltage of 380V for high-frequency induction melting, the corresponding current is 12A, and the melting process lasts for 3 minutes;

[0055] 3) Place the ingot body obtained in ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com