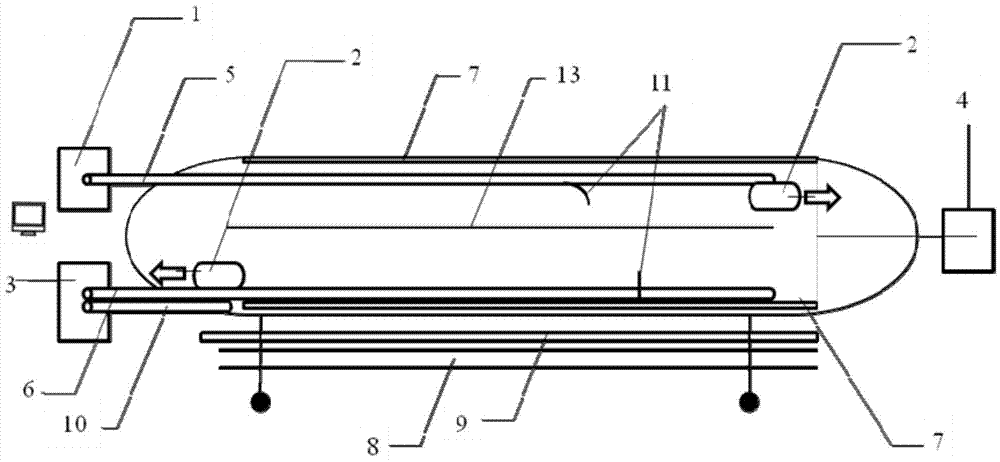

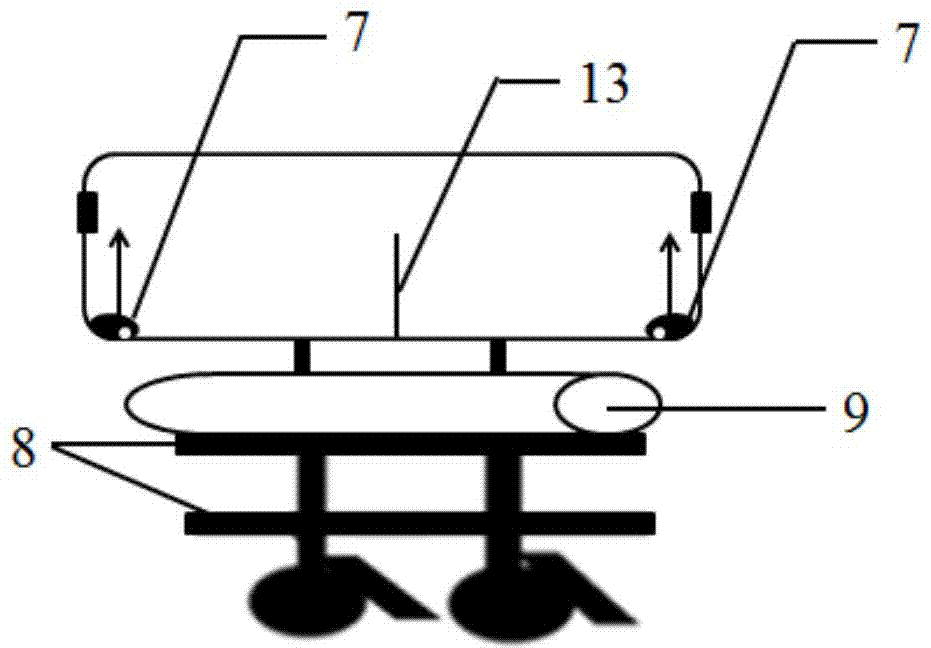

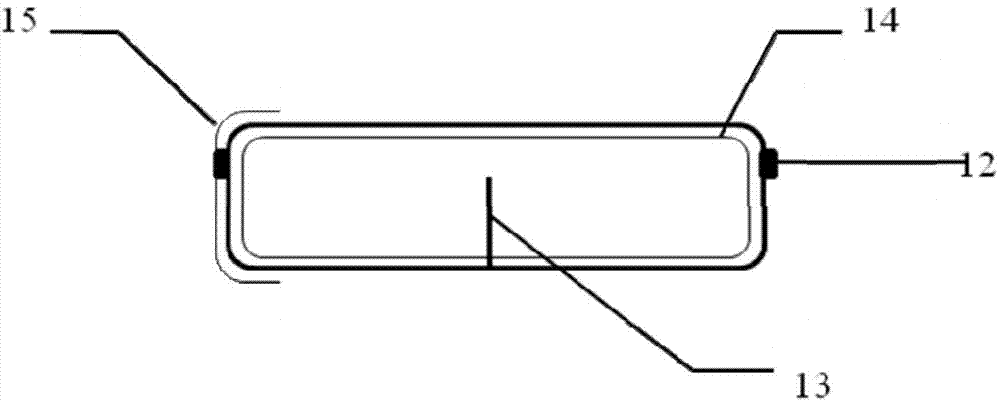

Runway type bioreactor applicable to sunshine factorization

A bioreactor, track-type technology, applied in specific-purpose bioreactor/fermenter, bioreactor/fermenter combination, microorganism-based methods, etc. It can avoid pollution, improve light utilization rate, and increase culture density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: Haematococcus pluvialis (Haematococcus pluvialis) cultivation

[0029] (1) experimental device is prepared: two lengths are 5m, and the width is 1m oval runway pond, and experimental group is device of the present invention, and matched group is cement open runway pond;

[0030] (2) Inoculation: On the first day, the Haematococcus pluvialis liquid was inoculated in the experimental group and the control group, so that the cell inoculation density was 2.5×10 4 cells / ml; and MCM culture solution is added to the pool, the height of the culture solution is 0.15m (liquid volume 750L); the average temperature and light intensity during the culture period: 13°C at 8:00, 130μmol / m 2 / s, 25°C at 13:00, 380μmol / m 2 / s, 13°C at 17:00, 150μmol / m 2 / s;

[0031] (3) Control management: the control group uses impeller stirring to make the culture solution mix and circulate in the pool, and the rotation speed in the whole culture cycle is 30r / min, without carbon dioxid...

Embodiment 2

[0033] Embodiment 2: Isochrysis galbana (Isochrysis galbana) culture

[0034] The method is the same as in Example 1, except that in step 2, the cell seeding density is 2×10 4 cells / ml; after 10 days of culture, the cell density of Isochrysis globosa in the experimental group reached 1.9×10 5 cells / ml, the cell density of Isochrysis globosa in the control group reached 1.1×10 5 cells / ml. Compared with the control group, the concentration of cell culture in the experimental group increased by 72.7%.

Embodiment 3

[0035] Embodiment 3: Phaeodactylum tricornutum Bohlin (Phaeodactylum tricornutum Bohlin) cultivation

[0036] The method is the same as in Example 1, except that in step 2, the cell seeding density is 1.5×10 4 cells / ml; after 10 days of culture, the cell density of Phaeodactylum tricornutum in the experimental group reached 1.7×10 5 cells / ml, the cell density of Phaeodactylum tricornutum in the control group reached 1.1×10 5 cells / ml. Compared with the control group, the concentration of cell culture in the experimental group increased by 54.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com