Method for producing three-carbon compounds by using gene engineering cyanobacteria

A three-carbon compound, genetic engineering technology, applied in genetic engineering, biochemical equipment and methods, botanical equipment and methods, etc., can solve problems such as time-consuming and cost, achieve cost saving of raw materials, avoid consumption, and broad application prospects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

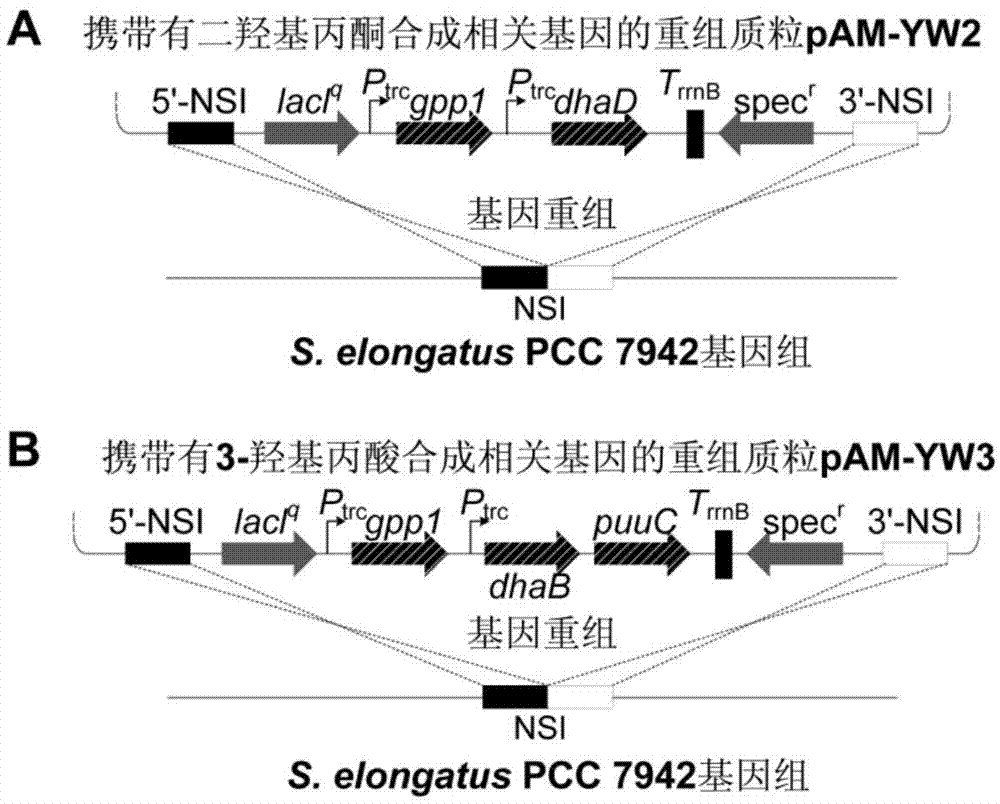

[0050] Example 1: Construction of plasmid pAM-YW2 carrying genes related to the synthesis pathway of dihydroxyacetone

[0051] 1) Extract pAM2991 plasmid

[0052] Escherichia coli DH5α (pAM2991) carrying the pAM2991 plasmid was inoculated into 5 mL of LB liquid medium containing spectinomycin (100 μg / mL) according to the inoculum size of 1%, and cultured in a shaker at 200 rpm at 37 ° C for 12 h . The pAM2991 plasmid was extracted from the cultured cells.

[0053] 2) Amplify the Ptrc promoter

[0054] Using synthetic primers, the Ptrc promoter was amplified by PCR from the pAM2991 plasmid.

[0055] Ptrc upstream primer 5'-AGATCTGACAGCTTATCATCGACT-3', carrying a BglII restriction site;

[0056] The downstream primer of Ptrc, 5'-CTCGAGTTCCATGGTCTGTTTCCT-3', carries an XhoI restriction site.

[0057] The above-mentioned Ptrc promoter has a sequence length of 268 bases, and its nucleotide sequence is shown in SEQ ID NO.9.

[0058] 3) Construction of pAM-P2 plasmid

[0059] ...

Embodiment 2

[0072] Example 2: Construction of plasmid pAM-YW3 carrying genes related to 3-hydroxypropionic acid synthesis pathway

[0073] 1) extract pAM-P2-gpp1 plasmid,

[0074] Escherichia coli DH5α (pAM2991) carrying the pAM-P2-gpp1 plasmid was inoculated into 5 mL of LB liquid medium containing spectinomycin (100 μg / mL) according to the inoculum size of 1%, and shaken at 200 rpm at 37°C. Cultured in bed for 12h. The pAM-P2-gpp1 plasmid was extracted from the cultured cells.

[0075] 2) Amplification of glycerol dehydratase gene dhaB

[0076] Genomic DNA of Clostridium butyricum DSM 10702 was prepared by a conventional method, and glycerol dehydratase gene dhaB was obtained by PCR amplification from the genomic DNA of Clostridium butyricum DSM 10702 using synthetic primers.

[0077] dhaB upstream primer 5'-CTCGAGATGATAAGTAAAGGATTTAG-3', carrying an XhoI restriction site;

[0078]The dhaB downstream primer 5'-GCGGCCGCTTACTCAGCTCCAATTGTGC-3' carries a NotI restriction site.

[0079...

Embodiment 3

[0087] Embodiment 3: the transformation of cyanobacteria and the screening of genetically engineered cyanobacteria

[0088] 1) Transformation of cyanobacteria strains

[0089] Synechococcus elongatus PCC 7942 was grown to OD 730nm 0.4-0.8, take 10mL of cyanobacteria culture solution, centrifuge at 5,000×g for 5 minutes, remove the supernatant to collect the bacteria; wash once with sterile 10mM NaCl, resuspend the bacteria with 5mL of fresh BG11 medium; take 500μL of cyanobacteria to resuspend Put the suspension into a 1.5mL centrifuge tube, add the recombinant plasmid with a final concentration of 100ng / mL, mix well, and incubate in the dark at 30°C for 12-18 hours; spread the mixture of cyanobacteria suspension and recombinant plasmid DNA on the BG11 solid Culture medium (containing spectinomycin 20 μg / mL), 30°C, 100 μE·s -1 m -2 Cultivate for 10-14 days under a certain light intensity until a single colony appears on the BG11 solid medium.

[0090] 2) Screening of genet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com