Production method for microbial flocculants

A microbial flocculant and production method technology, applied in the direction of microorganism-based methods, microorganisms, biochemical equipment and methods, etc., can solve the problems of poor flocculant flocculation effect and long production method cycle, and achieve good flocculation effect and low price , the effect of short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0016] Specific embodiment one: the production method of microbial flocculant of the present embodiment, carry out according to the following steps:

[0017] 1. Pick Acinetobacter and inoculate it into the rich medium, and cultivate it for 18h-24h under the conditions of 28°C-35°C, 140r / min-160r / min, and pH 6.5-7.5, to obtain the activated bacterial liquid, and the activated The bacterial solution is inserted into the flocculation medium according to the inoculum amount of 5%;

[0018] 2. Carry out fermentation culture according to the following conditions: the initial pH is 6-8, the culture temperature is 15°C-30°C, the rotating speed of the shaker is 120r / min-150r / min, and the culture time is 20h-30h to obtain the fermentation liquid;

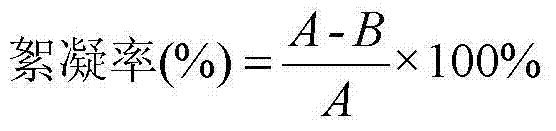

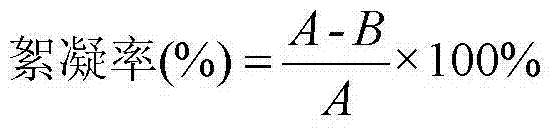

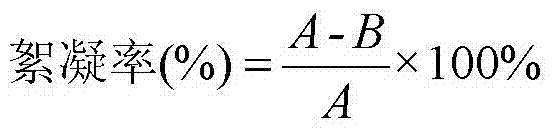

[0019] 3. Centrifuge the fermentation broth at 3000r / min for 10min, collect the bacterial precipitate, wash it with PBS for 2-3 times, then add the bacterial lysate, then perform ultrasonic crushing in ice bath for 20min, and centrifuge the o...

specific Embodiment approach 2

[0033] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the enrichment medium described in step one is made of 0.2g / L MgSO 4 ·7H 2 O, 5g / L glucose, 3.8g / L beef extract, 10g / L peptone, 16g / L agar and distilled water, pH 7.2. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0034] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the flocculation medium described in step one consists of 14~18g / L glucose, 8~12g / L sucrose, 0.5~0.8g / L yeast extract , 0.08~0.15g / L urea, 0.4~0.6g / L ammonium sulfate, 0.8~1.2g / L KH 2 PO 4, 2~3g / L K 2 HPO 4 , 0.2~0.4g / L MgSO 4 , 0.1~0.3g / L NaCl and distilled water. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com