Titanium metal material surface modifying method and modified titanium metal material

A surface modification, titanium metal technology, applied in metal material coating process, vacuum evaporation plating, coating and other directions, can solve the problem that the interaction of magnesium ions is not very ideal, to promote the osteogenic differentiation of cells, promote the formation of The effect of improving bone and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

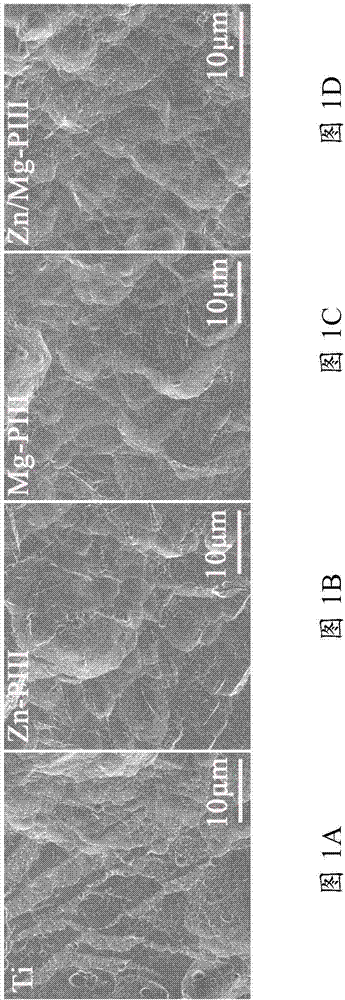

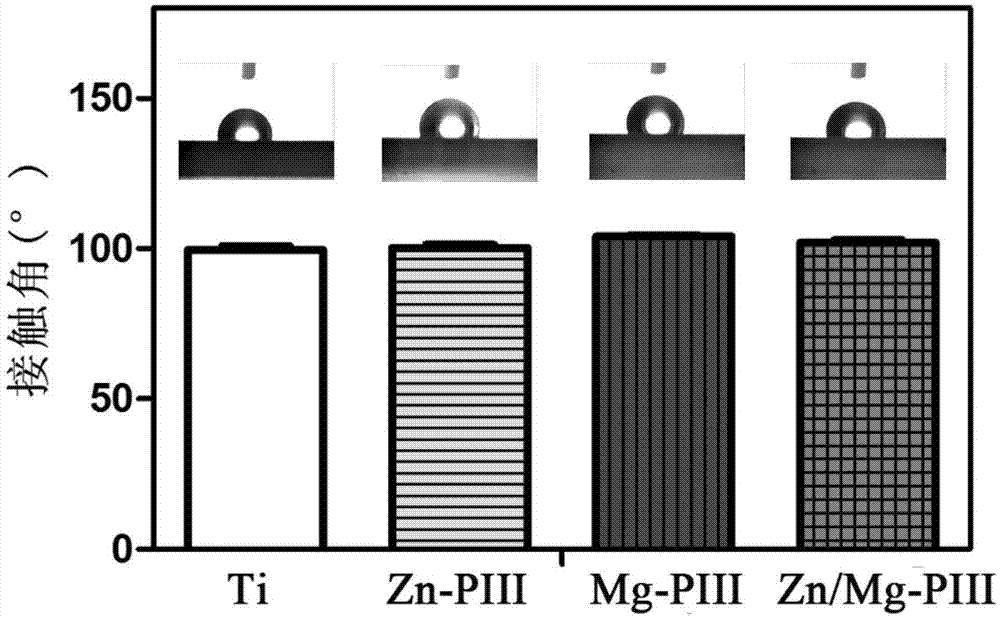

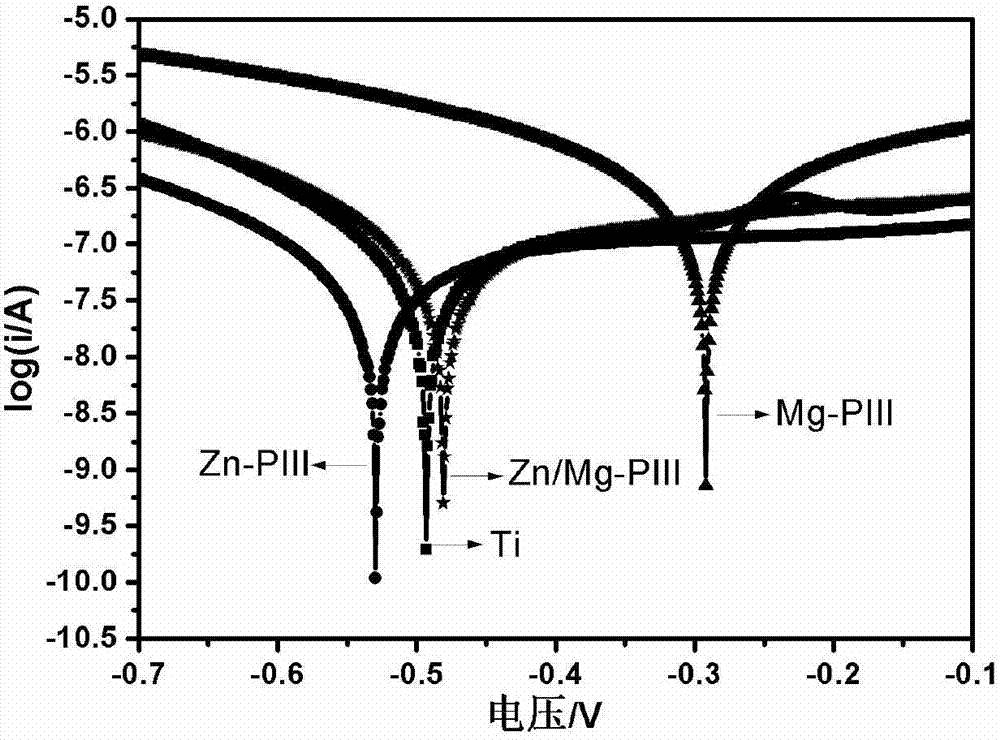

[0025] A pure titanium sheet with a size of 10mm×10mm×1mm was mixed with acid (HF:HNO 3 :H 2 (O=1:5:4, volume ratio) after cleaning for 10 minutes, use alcohol, deionized water and ultrapure water to clean it ultrasonically, each time for 10-20 minutes, and dry it naturally for use. The plasma immersion ion implantation (PIII) technology was used to co-implant zinc and magnesium ions onto the surface of pure titanium. The titanium surface was used as a control, and zinc-magnesium-injected modified, zinc-infused modified, and magnesium-infused modified titanium metal materials were respectively obtained. Their scanning electron microscope morphology is shown in Fig. 1, and the contact angle is figure 2 shown.

[0026] Table 1 Process parameters of PIII technology

[0027]

[0028] Note: The target indicates the titanium metal material on the sample stage, and the pulsed arc indicates the zinc plasma source and the magnesium plasma source.

[0029] As can be seen from F...

Embodiment 2

[0032] A pure titanium sheet with a size of 10mm×10mm×1mm was mixed with acid (HF:HNO 3 :H 2(O=1:5:4, volume ratio) after cleaning for 10 minutes, use alcohol, deionized water and ultrapure water to clean it ultrasonically, each time for 10-20 minutes, and dry it naturally for use. The plasma immersion ion implantation (PIII) technology was used to co-implant zinc and magnesium ions to the surface of pure titanium. The titanium surface was used as a control, and zinc-magnesium-injected modified, zinc-infused modified, and magnesium-infused modified titanium metal materials were respectively obtained.

[0033] The process parameter of table 2PIII technology

[0034]

[0035] Note: The target indicates the titanium metal material on the sample stage, and the pulsed arc indicates the zinc plasma source and the magnesium plasma source.

Embodiment 3

[0037] A pure titanium sheet with a size of 10mm×10mm×1mm was mixed with acid (HF:HNO 3 :H 2 (O=1:5:4, volume ratio) after cleaning for 10 minutes, use alcohol, deionized water and ultrapure water to clean it ultrasonically, each time for 10-20 minutes, and dry it naturally for use. The plasma immersion ion implantation (PIII) technology was used to co-implant zinc and magnesium ions to the surface of pure titanium, and the specific process parameters are shown in Table 3. At the same time, with the same process parameters, only zinc ions and magnesium ions were implanted alone to pure titanium. The titanium surface was used as a control, and zinc-magnesium-injected modified, zinc-infused modified, and magnesium-infused modified titanium metal materials were respectively obtained.

[0038] The process parameter of table 3PIII technology

[0039]

[0040] Note: The target indicates the titanium metal material on the sample stage, and the pulsed arc indicates the zinc plasm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com