Quinone compound-graphene composite material and preparation method thereof as well as flexible lithium secondary battery

A composite material and compound technology, applied in the field of energy materials, can solve the problems of poor electrical conductivity and poor stability, and achieve the effects of high capacity, good cycle stability, improved electrical conductivity and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

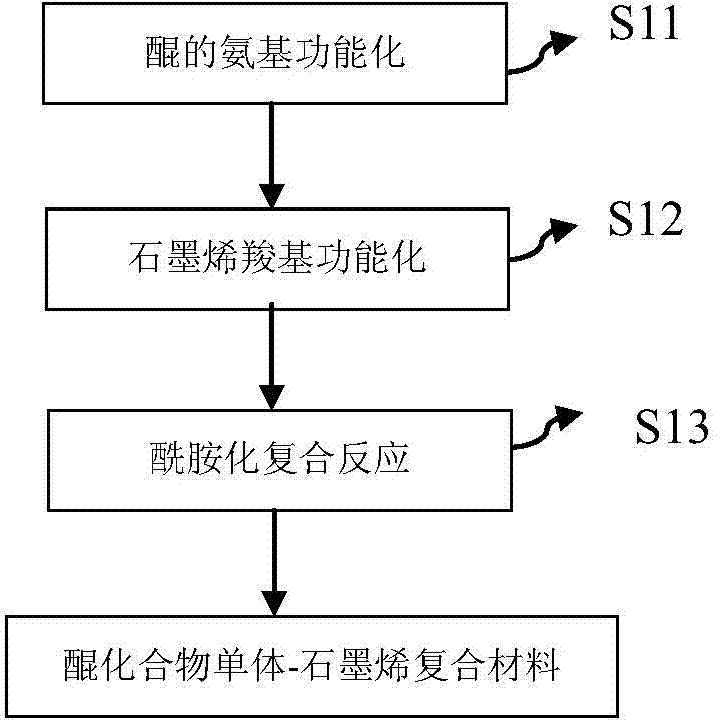

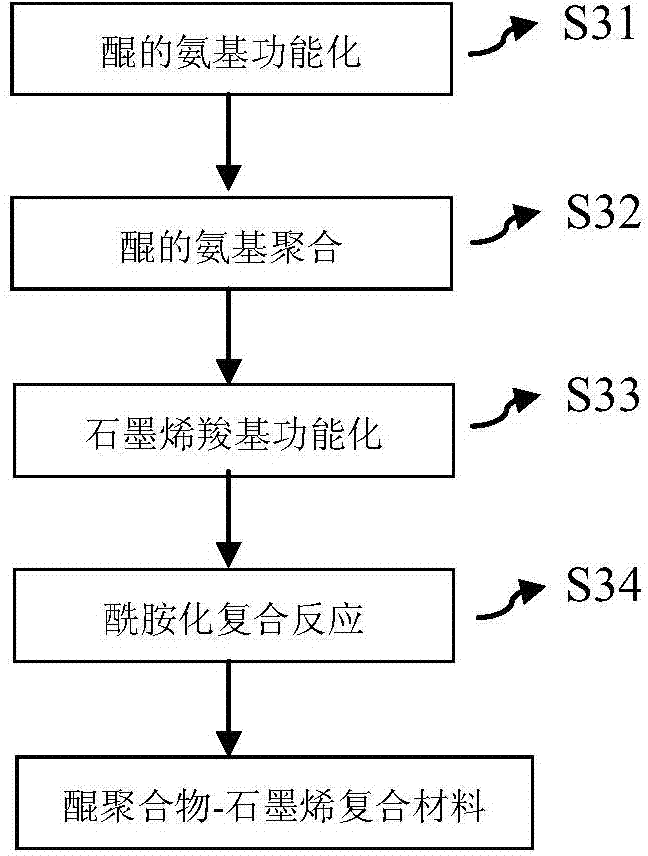

[0056] In a second aspect, an embodiment of the present invention provides a method for preparing a quinone compound-graphene composite material, comprising the following steps:

[0057] The quinone compound monomer is aminated by a nitration reduction method to obtain a mixed solution containing the aminated quinone compound monomer;

[0058] filtering, washing, and drying the mixed solution containing the aminated quinone compound monomer to obtain an aminated quinone compound monomer powder;

[0059] Add the graphene oxide powder into the mixed acid of concentrated sulfuric acid and concentrated nitric acid in a preset ratio, react at 50-60°C for 5-15 hours, then perform suction filtration, washing and vacuum drying to obtain surface carboxylated graphene powder body;

[0060] adding the aminated quinone compound monomer powder and the surface carboxylated graphene powder into water or ethanol, and ultrasonically dispersing to obtain a mixed dispersion;

[0061] The mixed...

Embodiment 1

[0097] A preparation method of quinone compound-graphene composite material, comprising the following steps:

[0098] Step S11, amination of p-benzoquinone: nitrate p-benzoquinone with a mixed acid of concentrated sulfuric acid and concentrated nitric acid by nitration reduction method to obtain dinitrated p-benzoquinone, and then add sodium sulfide for reduction to obtain aminated p-benzoquinone containing Mixed solution, the mixed solution is filtered, washed, and dried to obtain aminated p-benzoquinone powder; the amination reaction formula is shown in formula (1):

[0099]

[0100] Step S12, graphene carboxylation: add concentrated sulfuric acid and concentrated nitric acid mixed acid with a volume ratio of 3:1 to the graphene oxide powder, react at 60°C for 12 hours under the conditions of stirring and ultrasonic dispersion, filter through a filter membrane, distilled water After washing and vacuum drying, a carboxylated graphene powder with a large number of carboxyl ...

Embodiment 2

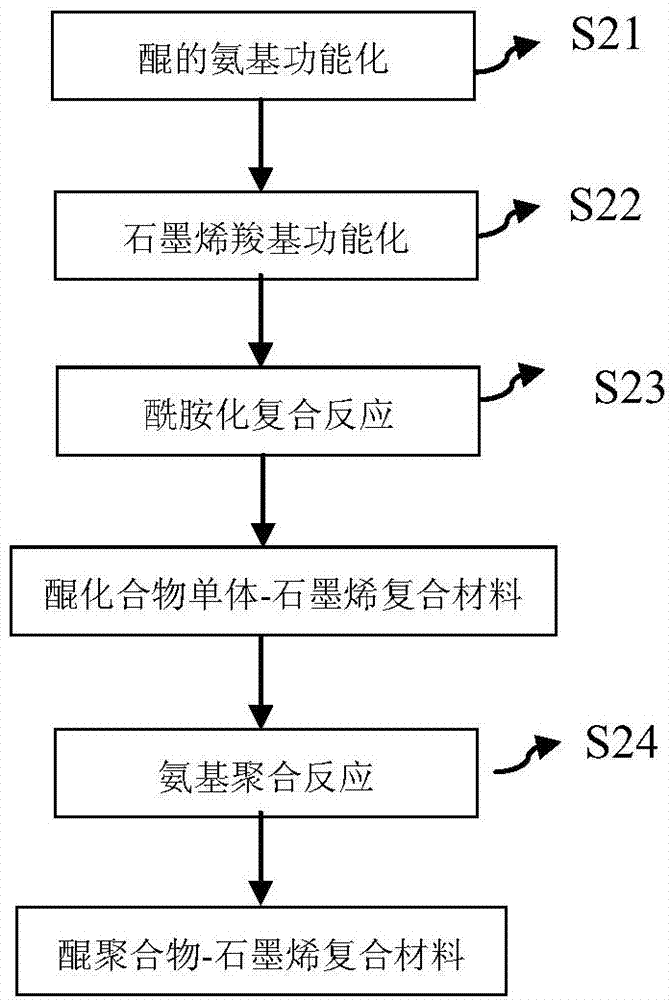

[0106] A preparation method of quinone compound-graphene composite material, comprising the following steps:

[0107] Step S21, amination of 1,5-anthraquinone: nitrate 1,5-anthraquinone with a mixed acid of concentrated sulfuric acid and concentrated nitric acid by nitration reduction method to obtain 1,5-dinitrated anthraquinone, and then add sodium sulfide for reduction , to obtain a mixed solution containing 1,5-diaminoanthraquinone, the mixed solution is filtered, washed, and dried to obtain 1,5-diaminoanthraquinone powder; the amination reaction formula is as shown in formula (4) Shown:

[0108]

[0109] Step S22, graphene carboxylation: add concentrated sulfuric acid and concentrated nitric acid mixed acid with a volume ratio of 3:1 to the graphene oxide powder, react at 50°C for 12 hours under the conditions of stirring and ultrasonic dispersion, filter through a filter membrane, distilled water After washing and vacuum drying, carboxylated graphene powder with a la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com