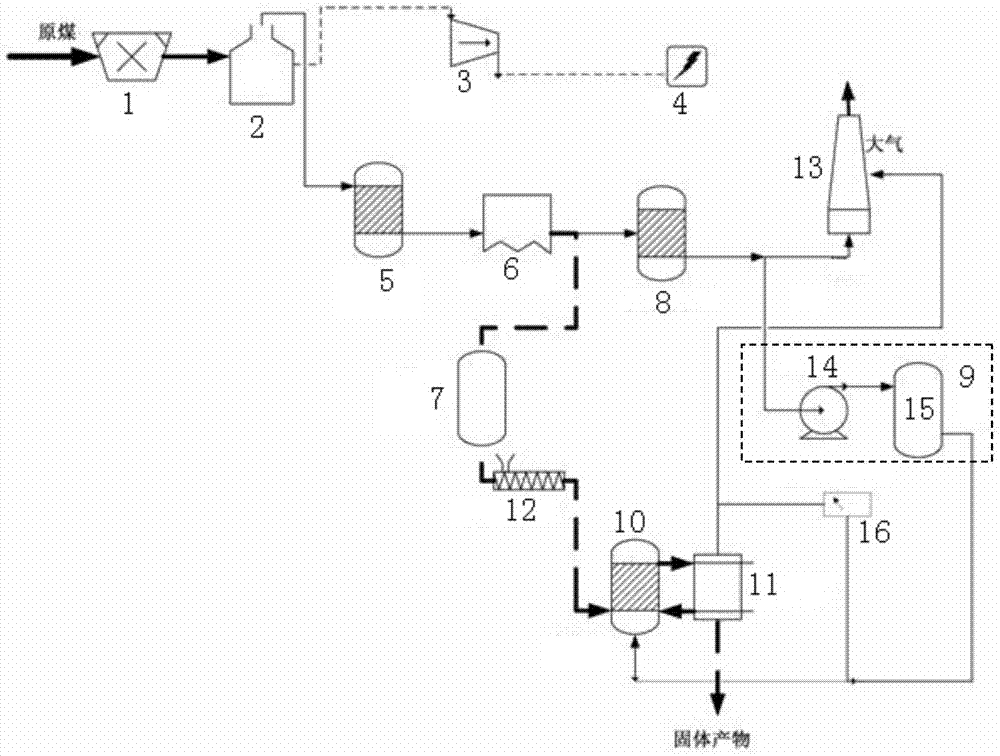

Fluidized bed technology and fluidized bed system for directly capturing CO2 in mineralized flue gas

A technology of carbon dioxide and fluidized bed, applied in air quality improvement, chemical instruments and methods, separation of dispersed particles, etc., can solve the problems of difficult recovery of chemical reagents, harsh reaction conditions, high raw material prices, etc., and achieve rapid carbonation reaction, equipment Less, the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Fluidized bed process for directly capturing carbon dioxide in mineralized flue gas, using high-calcium fly ash from pulverized coal furnace as raw material, CaO content is about 30%, and the main crystal phase is mullite, quartz and a large amount of glassy amorphous state SiO 2 , D50 is 80 microns, the specific steps are as follows:

[0040] In the first step, after analyzing the gray sample, CaO was found to be CaSiO 3 The form exists, and the reactivity meets the requirements. In order to further improve the reactivity, the fly ash is finely ground to reduce the particle size to D50 of 20 microns. Generally, a dry powder grinder is used for 20 minutes of grinding. Fly ash can be sampled from the ash bin of the power plant with a pneumatic soot blowing system.

[0041] The second step is to open a bypass on the flue after the desulfurization of the power plant to lead a stream of flue gas. First, the pressure is increased to 2bar through the booster, and then adjus...

Embodiment 2

[0045] Fluidized bed process for directly capturing carbon dioxide in mineralized flue gas, using fluidized bed desulfurization fly ash as raw material, CaO content is about 18%, the main crystal phase is a large amount of mullite, amorphous SiO 2 and free CaO, D50 is 40 microns, the specific steps are as follows:

[0046] In the first step, after analyzing the gray sample, it is found that CaO exists in the form of fCaO, and the reactivity meets the requirements without pretreatment. Samples can be delivered from the power plant ash silo using a pneumatic soot blowing system.

[0047] The second step is to open a bypass on the flue after the desulfurization of the power plant to lead a stream of flue gas. First, the pressure is increased to 2bar through the booster, and then adjusted by the temperature and humidity regulator. The temperature is adjusted to 90 degrees Celsius, and the humidity adjustment range 30%.

[0048] In the third step, the flue gas with adjusted tempe...

Embodiment 3

[0051] Fluidized bed process for directly capturing carbon dioxide in mineralized flue gas, using low-calcium fly ash from pulverized coal furnace as raw material, with a CaO content of about 5%, and the main crystal phases are mullite, quartz and a large amount of glass amorphous SiO 2 , D50 is 80 microns, the specific steps are as follows:

[0052] In the first step, after analyzing the gray sample, CaO was found to be CaSiO 3 Alkaline desiliconization is required to meet the requirements of activity and ash-gas ratio. Use 15% NaOH solution to dissolve the fly ash under the condition of 90 degrees and 800 rpm stirring speed, the liquid-solid ratio is 5:1, filter and dry after dissolving for 2 hours to obtain the treated fly ash. In order to further increase the reactivity, the treated fly ash can be heated at 600 degrees for 2 hours.

[0053] The second step is to open a bypass on the desulfurized flue of the power plant to lead a stream of flue gas, first through the boo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com