Enzymic preparation treatment method for disposable chopstick production

A production method and enzyme preparation technology, applied in the field of disposable bamboo chopsticks production and processing, can solve the problems of easy discoloration and mildew of bamboo chopsticks, high leaching of sulfur dioxide as a microbial indicator of bamboo chopsticks, and health hazards of consumers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

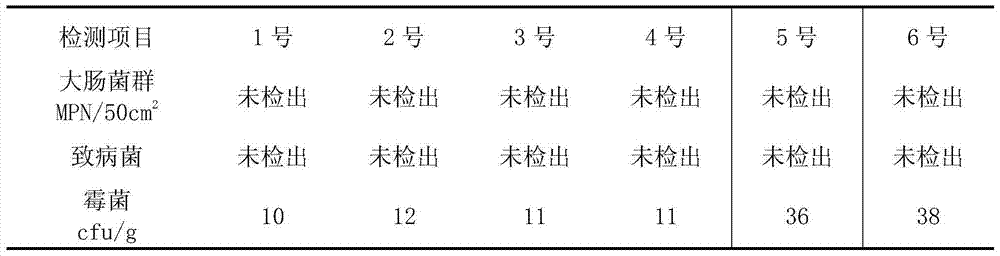

Examples

Embodiment 1

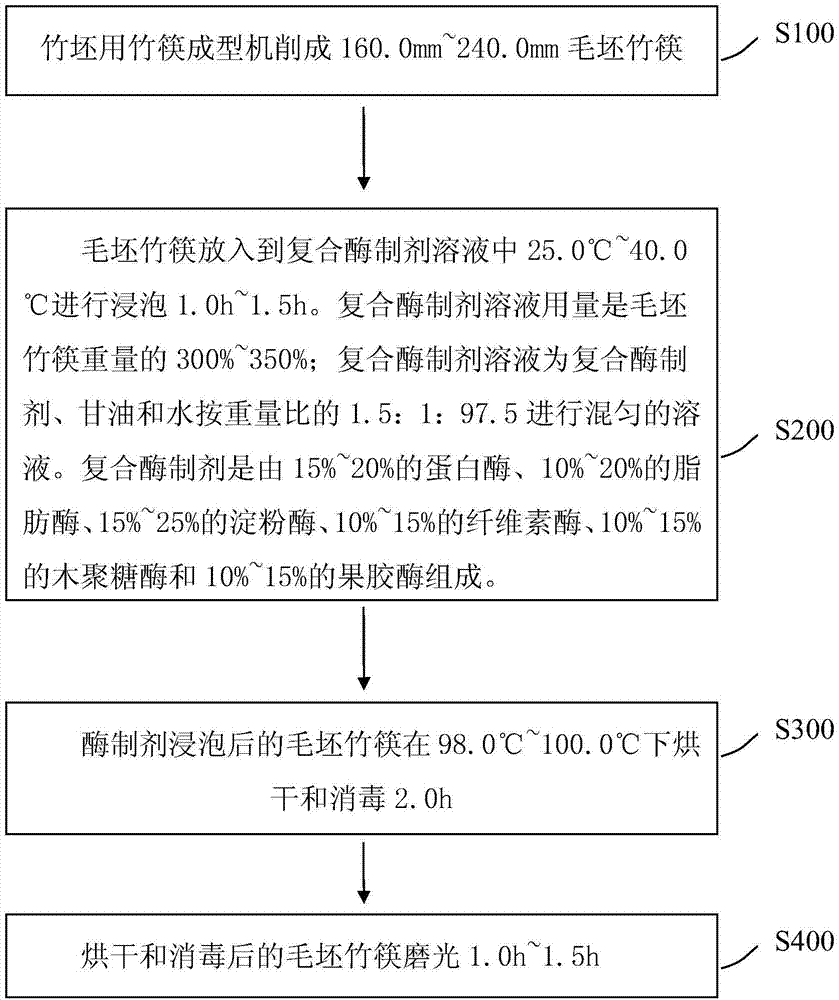

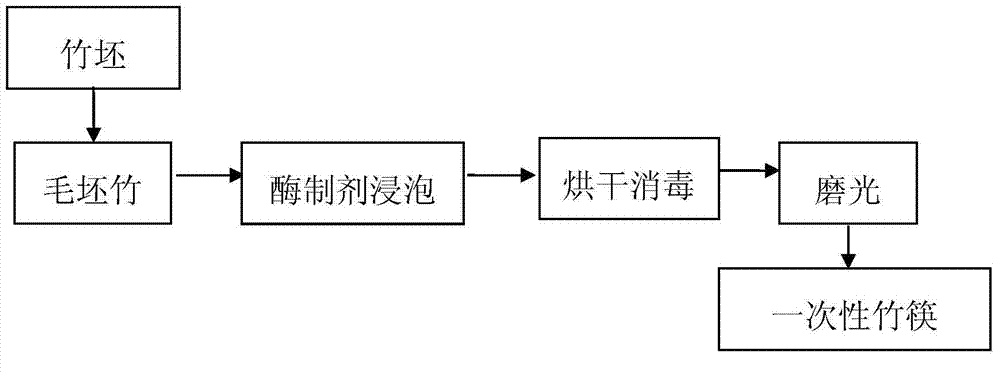

[0034] A production method for treating disposable bamboo chopsticks with an enzyme preparation, comprising the following steps:

[0035] ⑴ Cut the bamboo blank into 160mm long rough bamboo chopsticks with a bamboo chopsticks forming machine.

[0036] (2) Put 200kg of rough bamboo chopsticks obtained in step (1) into 600kg of compound enzyme solution and soak for 1 hour at 25°C.

[0037] The compound enzyme preparation solution is a solution obtained by dissolving the compound enzyme preparation in an aqueous solution containing glycerin; the compound enzyme preparation, glycerin and water are mixed at a weight ratio of 1.5:1:97.5.

[0038] The compound enzyme preparation is composed of protease, lipase, amylase, cellulase, xylanase and pectinase, and its mass fractions are 25%, 20%, 25%, 10%, 10% and 10% respectively.

[0039] (3) Dry and sterilize the rough bamboo chopsticks soaked in the enzyme preparation obtained in step (2) at 98.0° C. for 2.0 h.

[0040] (4) Polishing...

Embodiment 2

[0042] A production method for treating disposable bamboo chopsticks with an enzyme preparation, comprising the following steps:

[0043] ⑴ Cut the bamboo blank into 240mm long rough bamboo chopsticks with a bamboo chopsticks forming machine.

[0044] (2) Put 200kg of rough bamboo chopsticks obtained in step (1) into 600kg of compound enzyme preparation solution and soak at 40°C for 1.5h.

[0045] The compound enzyme preparation solution is a solution obtained by dissolving the compound enzyme preparation in an aqueous solution containing glycerin; the compound enzyme preparation, glycerin and water are mixed at a weight ratio of 1.5:1:97.5.

[0046] The compound enzyme preparation is composed of protease, lipase, amylase, cellulase, xylanase and pectinase, and its mass fractions are 15%, 20%, 20%, 15%, 15% and 15% respectively.

[0047] (3) Dry and sterilize the rough bamboo chopsticks soaked in the enzyme preparation obtained in step (2) at 100.0° C. for 2.0 h.

[0048] (4...

Embodiment 3

[0050] A production method for treating disposable bamboo chopsticks with an enzyme preparation, comprising the following steps:

[0051] ⑴ Cut the bamboo blank into 200mm long rough bamboo chopsticks with a bamboo chopsticks forming machine.

[0052] (2) Put 200kg of rough bamboo chopsticks obtained in step (1) into 600kg of compound enzyme preparation solution and soak at 30°C for 1.2h.

[0053]The compound enzyme preparation solution is a solution obtained by dissolving the compound enzyme preparation in an aqueous solution containing glycerin; the compound enzyme preparation, glycerin and water are mixed at a weight ratio of 1.5:1:97.5.

[0054] The compound enzyme preparation is composed of protease, lipase, amylase, cellulase, xylanase and pectinase, and its mass fractions are 20%, 20%, 20%, 15%, 15% and 10% respectively.

[0055] (3) Dry and sterilize the rough bamboo chopsticks soaked in the enzyme preparation obtained in step (2) at 99.0° C. for 2.0 h.

[0056] (4) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com