Preparation method of cross-linked sodium hyaluronate gel having hyaluronidase activity inhibiting effect

A technology of cross-linking hyaluronic acid and hyaluronidase, which is applied in the fields of medical science and prostheses, which can solve the problems of limited application, large pushing force, difficult small-caliber syringe needles, etc., and improve biological safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

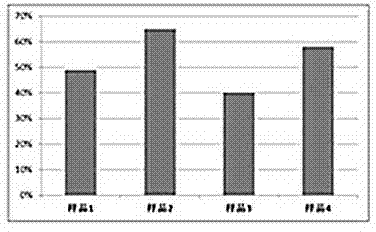

Image

Examples

Embodiment 1

[0024] Weigh 10 g of sodium hyaluronate dry powder with a molecular weight of 1.2 million Daltons, 5 g of γ-polyglutamic acid dry powder with a molecular weight of 1 million, and use 0.5% ( w / w) hydrochloric acid solution to dissolve it, and then react at room temperature 25°C for 24 hours to obtain an acidic cross-linked gel. Then add 100 ml of 1% sodium hydroxide solution to the acidic cross-linked gel, dissolve evenly, put it in a constant temperature and humidity reaction cabinet at 5°C and react for 7 days to obtain an alkaline cross-linked gel. The secondary cross-linked gel was diluted to 1000ml with 0.5% sodium hydroxide, then precipitated with 95% ethanol, and washed twice. Then, the obtained dry powder was dissolved into 400ml by using phosphate buffer solution, and after dissolving evenly, it was put into a dialysis bag and dialyzed for 3 days to obtain sample 1.

Embodiment 2

[0026] Weigh 12 g of sodium hyaluronate dry powder with a molecular weight of 1.2 million Daltons, 5 g of γ-polyglutamic acid dry powder with a molecular weight of 1 million, and use 0.5% ( w / w) hydrochloric acid solution to dissolve it, and then react at room temperature 25°C for 48 hours to obtain an acidic cross-linked gel. Then add 100ml of potassium hydroxide solution with a concentration of 1% to the acidic cross-linked gel, dissolve evenly, put it into a constant temperature and humidity reaction cabinet at 5°C and react for 7 days to obtain an alkaline cross-linked gel. The secondary cross-linked gel was diluted to 1000ml with 0.5% potassium hydroxide, then precipitated with 95% ethanol, and washed twice. Then, the obtained dry powder was dissolved to 400ml with phosphate buffer solution, and after dissolving evenly, it was put into a dialysis bag and dialyzed for 5 days to obtain sample 2.

Embodiment 3

[0028] Weigh 12 g of sodium hyaluronate dry powder with a molecular weight of 1.2 million Daltons, 5 g of γ-polyglutamic acid dry powder with a molecular weight of 1 million, and use 0.5% ( w / w) hydrochloric acid solution to dissolve it, and then react at room temperature 25°C for 48 hours to obtain an acidic cross-linked gel. Then add 100 ml of potassium hydroxide solution with a concentration of 1% to the acidic cross-linked gel, dissolve evenly, put it in a constant temperature and humidity reaction cabinet at 5°C and react for 5 days to obtain an alkaline cross-linked gel. The secondary cross-linked gel was diluted to 1000ml with 0.5% potassium hydroxide, then precipitated with 95% ethanol, and washed twice. Then, the obtained dry powder was dissolved to 400ml with phosphate buffer solution, and after dissolving evenly, it was put into a dialysis bag and dialyzed for 5 days to obtain sample 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com