Water-soluble polyurethane external-wall thermal-insulation waterproof paint and preparation method thereof

A technology of water-soluble polyurethane, heat insulation and heat preservation, applied in polyurea/polyurethane coatings, anti-corrosion coatings, anti-fouling/underwater coatings, etc., to achieve the effects of strong chemical resistance, good flexibility, and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

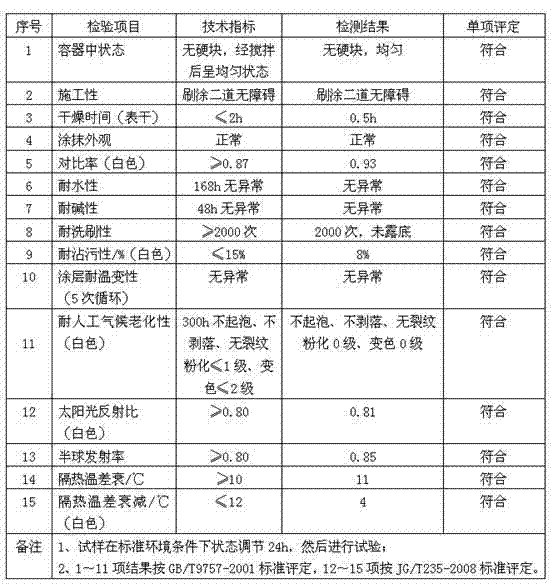

Image

Examples

Embodiment 1

[0038] First, 40 parts of polyurethane prepolymer, 1 part of N-methylolacrylamide, 2 parts of dibutyl phthalate, 0.5 parts of vinyl trichlorosilane, 10 parts of rutile titanium dioxide, and defoaming 0.1 part of methyl silicone oil; 5 parts of superfine calcium carbonate (300 mesh); 10 parts of mixed solvent (a mixture of lignin and ethylene glycol butyl ether with water, the weight ratio is 3:1:10); leveling agent polyacrylic acid The parts by weight of the ester is 1, and the yellow iron oxide is 2 parts, and the materials are prepared.

[0039] The production method is to add 2 kilograms of ethanol with a volume concentration of 50-70% per kilogram of N-methylolacrylamide to dissolve, and then mix it with polyurethane prepolymer in a reaction kettle. The reaction temperature is 80-150 ° C, and the reaction time is 1 After 1 hour, add vinyltrichlorosilane; continue to react for 2-5 hours; then add dibutyl phthalate, methyl silicone oil, superfine calcium carbonate, leveling ...

Embodiment 2

[0041] Firstly, 45 parts of polyurethane prepolymer, 2 parts of N-methylolacrylamide, 4 parts of dibutyl phthalate, 0.8 part of vinyl trichlorosilane, 15 parts of rutile titanium dioxide, 0.2 parts of antifoaming agent methyl silicone oil; 7 parts of superfine calcium carbonate (300 mesh); 12 parts of mixed solvent (a mixture of lignin and ethylene glycol butyl ether plus water, the weight ratio is 3:1:10); anti-settling agent Prepare 1 part of N-methylpyrrolidone solution of modified polyurea.

[0042] The production method is to add 2 kilograms of ethanol with a volume concentration of 50-70% per kilogram of N-methylolacrylamide to dissolve, and then mix it with polyurethane prepolymer in a reaction kettle. The reaction temperature is 80-150 ° C, and the reaction time is 1 After 1 hour, add vinyltrichlorosilane; continue to react for 2-5 hours; then add dibutyl phthalate, methyl silicone oil, superfine calcium carbonate, mixed solvent, anti-settling agent, and mix well to ob...

Embodiment 3

[0044] First, 50 parts of polyurethane prepolymer, 2 parts of N-methylolacrylamide, 5 parts of dibutyl phthalate, 1 part of vinyl trichlorosilane, 20 parts of rutile titanium dioxide, 0.3 parts of antifoaming agent methyl silicone oil; 10 parts of superfine calcium carbonate (300 mesh); 15 parts of mixed solvent (a mixture of lignin and ethylene glycol butyl ether plus water, the weight ratio is 3:1:10); antifreeze 1 part of 1,3-propanediol and 1 part of iron oxide red are prepared.

[0045] The production method is to add 2 kilograms of ethanol with a volume concentration of 50-70% per kilogram of N-methylolacrylamide to dissolve, and then mix it with polyurethane prepolymer in a reaction kettle. The reaction temperature is 80-150 ° C, and the reaction time is 1 After 1 hour, add vinyltrichlorosilane; continue to react for 2-5 hours; then add dibutyl phthalate, methyl silicone oil, superfine calcium carbonate, mixed solvent, propylene glycol, red iron oxide, and mix well to g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com