Midwifery gel preparation method

A gel and reactor technology, applied in the field of midwifery gel preparation, can solve the problems of increasing local and systemic infections, weakening the lubricating effect of lubricant compositions, and unfavorable babies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Recipe 1

[0063] Propylene glycol: 200g / L

[0064] Hydroxyethyl cellulose: 45g / L

[0065] Carbomer 940: 2g / L

[0066] Hyaluronic acid: 3g / L (molecular weight about 50w)

[0067] Purified water: make up 1L

[0068] NaOH: 10% (mass concentration) to adjust the pH to 5.5‐5.6

[0069] Acetic acid buffer salt: 1.6% acetic acid buffer solution (4.8ml 0.2mol / l acetic acid plus 45.2ml 0.2mol / l sodium acetate), pH about 5.6

[0070] Preparation Process:

[0071] Slime configuration:

[0072] A drawing slime configuration: Add 5L of 10% Nacl solution to Reactor 1. Sprinkle 300g of hyaluronic acid slowly, stir at 100rpm for 10min, turn on the vacuum, add 20L of purified water while stirring, increase the speed to 200rpm after 5min and continue stirring for 15min to defoam. Store at room temperature for later use (keep stirring at 50rpm without stopping)

[0073] B configuration of water-based thickener: Sprinkle 200g of carbomer slowly into the reaction kettle 1, stir at...

Embodiment 2

[0089] Recipe 2

[0090] Propylene glycol: 200g / L

[0091] Hydroxyethyl cellulose: 45g / L

[0092] Carbomer 980: 2g / L

[0093] Hyaluronic acid: 3g / L (molecular weight about 15w)

[0094] Purified water: make up 1L

[0095] NaOH: 10% (mass concentration) to adjust the pH to 5.5‐5.6

[0096] Acetic acid buffer salt: 1.6% acetic acid buffer solution (4.8ml 0.2mol / l acetic acid plus 45.2ml 0.2mol / l sodium acetate), pH about 5.6

[0097] Refer to Example 1 for the preparation process.

experiment example 1

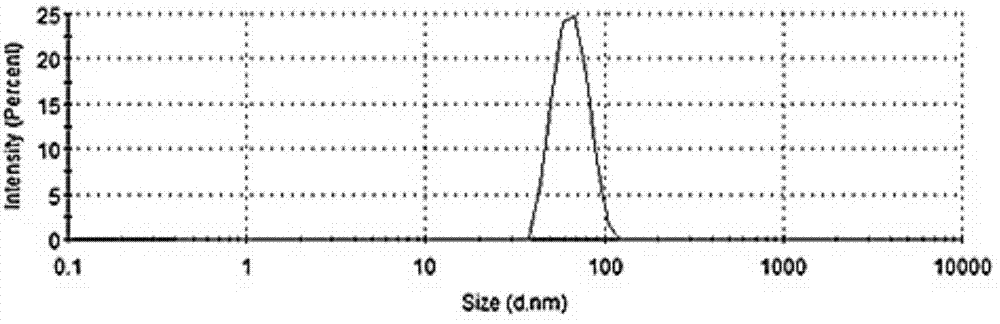

[0098] Experimental Example 1 Determination of microsphere particle size

[0099] Using Malvern ZS90, software: Zetasizer Software7.02, measurement conditions: dilution solvent: water, Material RI: 1.59, solvent refractive index: 1.330, number of cycles: 3 times, viscosity (cP): 0.8872, material absorption value: 0.010, temperature (°C): 25.0, cycle duration (s): 80, sampling rate (kcaps): 149.2, measurement position (mm): 4.65, cell: glass cuvette, attenuator: 6. The measurement results are shown in Table 1 and the measurement result curves are shown in figure 1 ; figure 1 The abscissa is the particle size (exponential distribution), and the ordinate is the light intensity.

[0100] Table 1 Particle size distribution of calcium alginate microspheres

[0101]

Diameter (d.nm)

Standard deviation (d.nm)

Average particle size: 63.78

Peak 1:

65.99

100.0

13.83

Particle size distribution: 0.002

Peak 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com