Carbon-coated ferrous lithium silicate anode material, as well as preparation method and application thereof

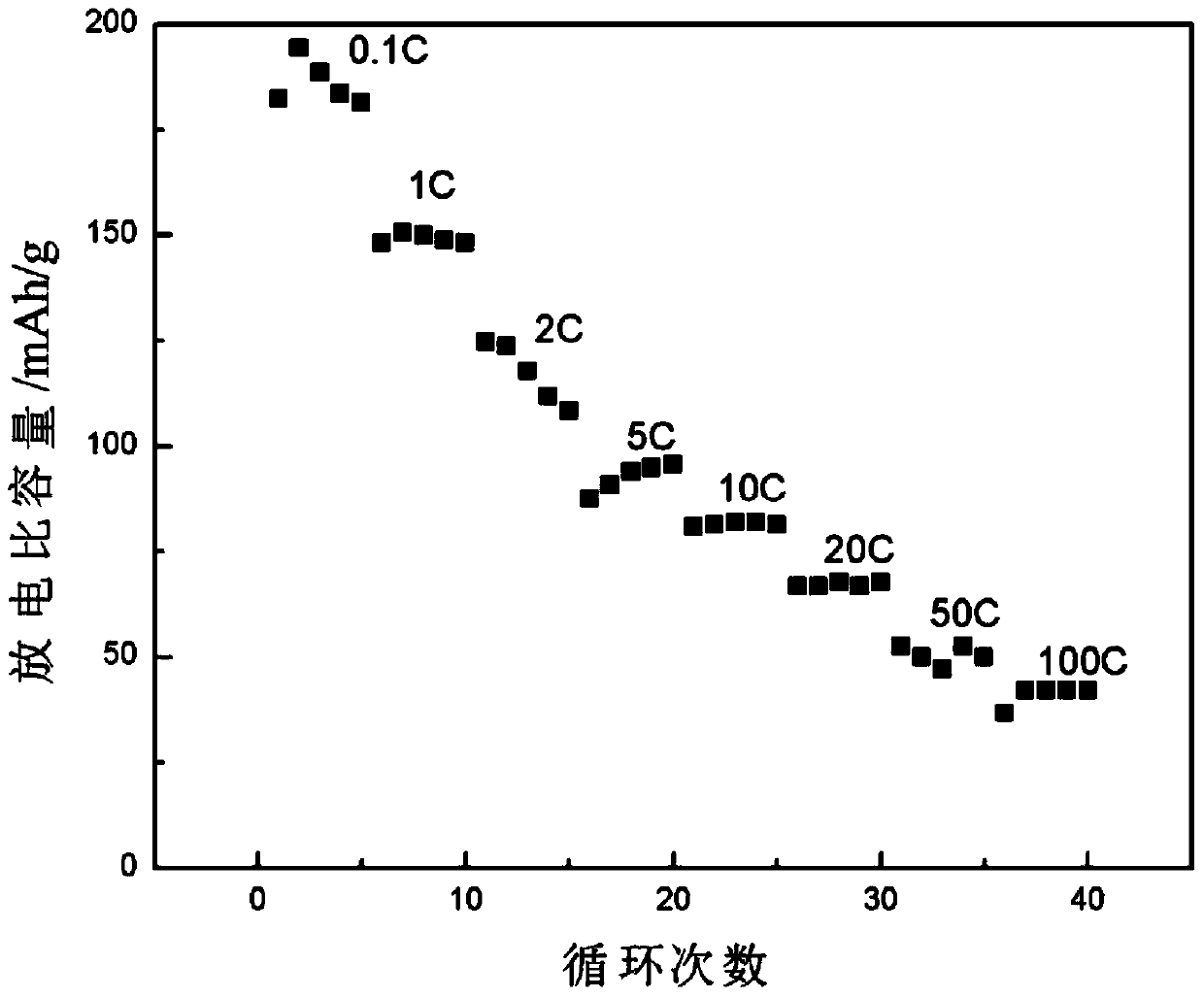

A technology of lithium ferrous silicate and positive electrode materials, which is applied in the direction of battery electrodes, electrical components, electrochemical generators, etc., can solve the problem that it is difficult to obtain a uniform bivalent lithium iron silicate material, and the performance of the battery is not too high. Good, strong corrosion of ferric nitrate and other issues, to achieve superior high-rate performance and cycle performance, superior high-rate performance, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

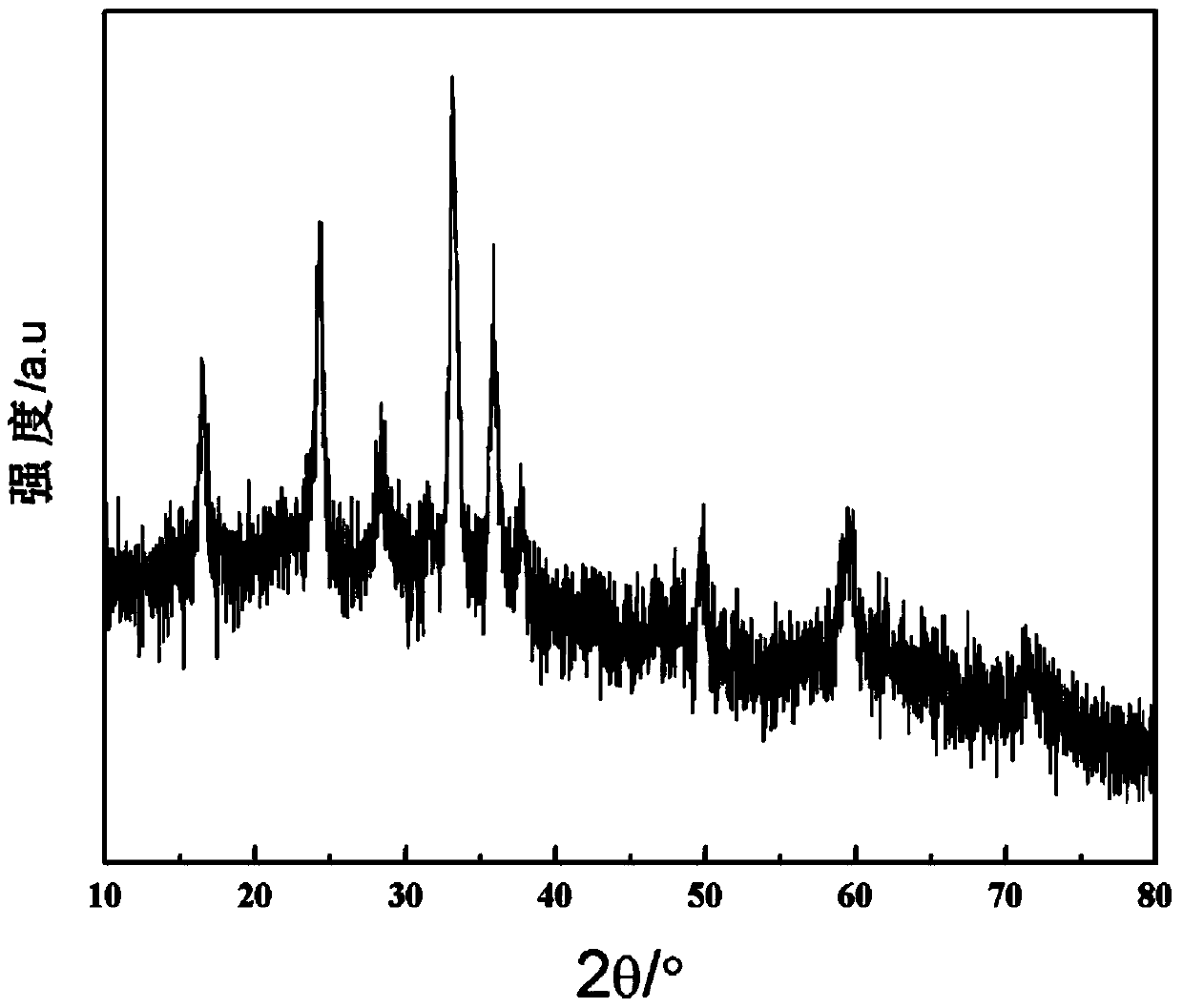

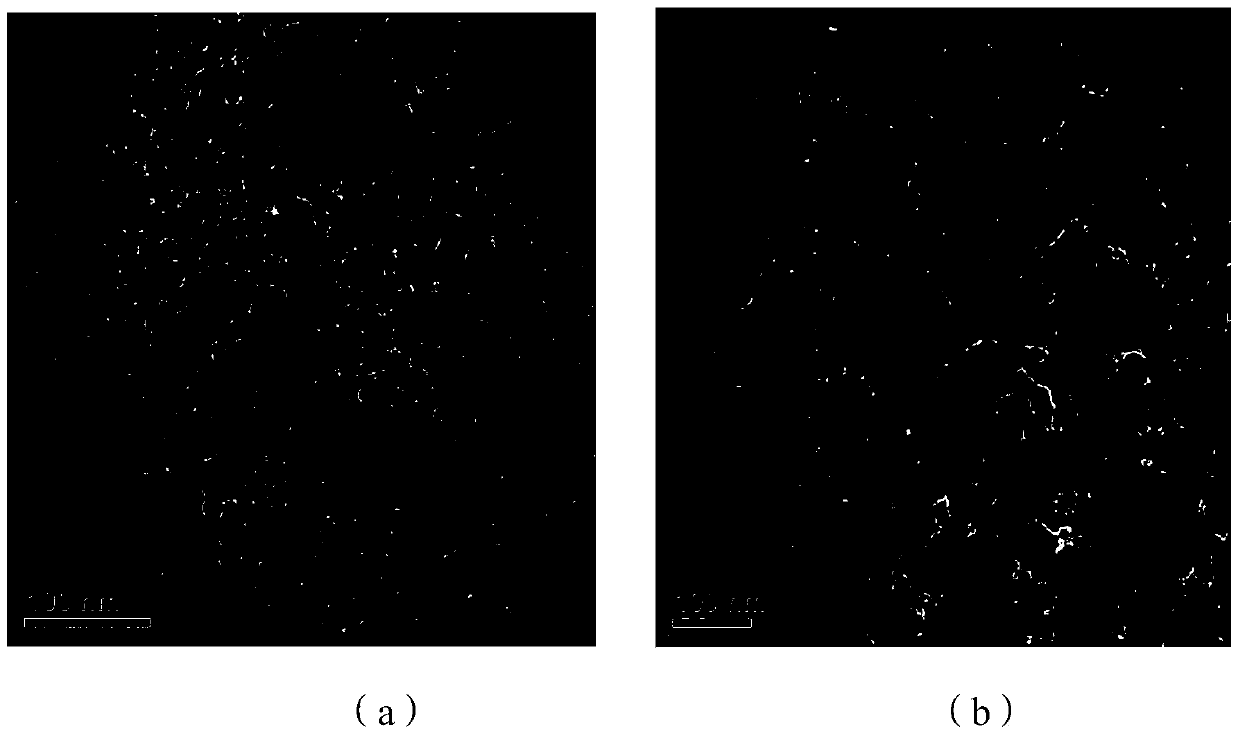

[0053] Add 0.02mol of iron powder and 0.02mol of citric acid into 60ml of deionized water, stir magnetically at a constant temperature of 60°C until the iron powder is completely dissolved into a dark green transparent solution; add 0.02mol of lithium carbonate and 0.02mol of Dissolve citric acid in 60mL of deionized water, stir magnetically for 2h at room temperature; disperse 0.02mol of nano-silica in 30ml of deionized water, and disperse ultrasonically for 2h; mix the above three solutions, stir well at room temperature for 4h to obtain dispersion Uniform solution; the mixed solution was evaporated to dryness with magnetic stirring at a constant temperature of 80°C to obtain a precursor; the above precursor was pre-decomposed at 220°C for 16 hours; the pre-decomposed product was moved into a high-temperature atmosphere furnace, protected by argon or nitrogen After sintering at 600°C for 4 hours, and cooling to room temperature with the furnace, a single-phase and uniform car...

Embodiment 2

[0055] Add 0.02mol of iron powder and 0.02mol of ascorbic acid into 60ml of deionized water, stir magnetically at a constant temperature of 60°C until the iron powder is completely dissolved into a dark green transparent solution; add 0.02mol of lithium hydroxide and 0.02mol of Dissolve ascorbic acid in 60mL deionized water, stir magnetically for 2h at room temperature; disperse 0.02mol nano-silica in 30ml deionized water, and disperse ultrasonically for 2h; mix the above three solutions, stir well at room temperature for 4h to obtain uniform dispersion solution; the mixed solution was evaporated to dryness with magnetic stirring at a constant temperature of 60°C to obtain a precursor; the above precursor was pre-decomposed at 200°C for 20 hours; the pre-decomposed product was moved into a high-temperature atmosphere furnace, under the protection of argon or nitrogen After sintering at 600°C for 4 hours, and cooling to room temperature with the furnace, a single-phase and unifo...

Embodiment 3

[0057] Add 0.02mol of iron powder and 0.02mol of formic acid into 60ml of deionized water, stir magnetically at a constant temperature of 60°C until the iron powder is completely dissolved into a dark green transparent solution; add 0.02mol of lithium acetate and 0.02mol of formic acid Dissolve in 60mL of deionized water, stir magnetically for 2h at room temperature; disperse 0.02mol of nano-silica in 30ml of deionized water, and disperse ultrasonically for 2h; mix the above three solutions, stir thoroughly at room temperature for 4h to obtain a uniformly dispersed solution; the mixed solution was evaporated to dryness with magnetic stirring at a constant temperature of 100°C to obtain a precursor; the above precursor was pre-decomposed at 260°C for 6 hours; the pre-decomposed product was moved into a high-temperature atmosphere furnace, and placed in After sintering at 600°C for 4 hours, and cooling to room temperature with the furnace, a single-phase and uniform carbon-coated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com