A kind of anaerobic treatment method of livestock and poultry manure

A technology for anaerobic treatment of livestock and poultry manure, which is applied in the field of resource and energy utilization of livestock and poultry manure, can solve the problems of reduced net gas production and low solid content, and achieve increased solid content, high solid content, The effect of low hygiene risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

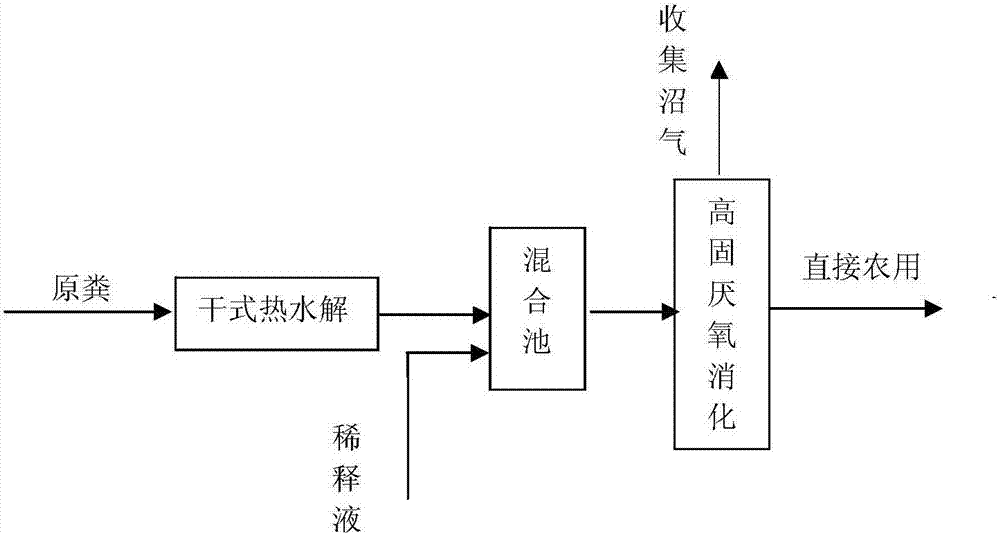

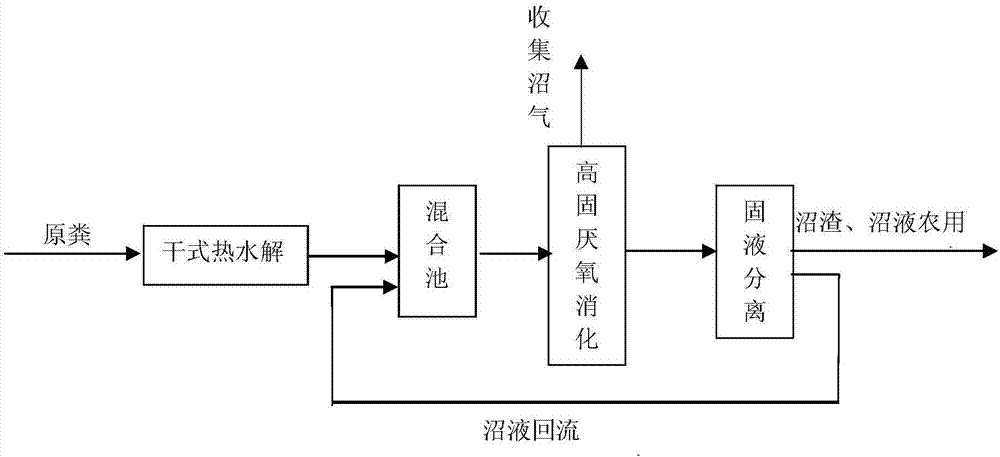

Method used

Image

Examples

Embodiment 1

[0017] Example 1: Pig manure with a solid content rate of 25.6% is directly put into the thermal hydrolysis tank for dry low-temperature thermal hydrolysis, the heating temperature is 70°C, and the solid residence time is 1 day; the feces after dry low-temperature thermal hydrolysis After diluting to a solid content rate of 12%, carry out anaerobic digestion, the reaction temperature is 35 ° C, the solid residence time is 14 days, and the methane yield is 284.4 mL / g (as CH 4 / VS), which is 49.7% higher than that of raw manure.

Embodiment 2

[0018] Example 2: Chicken manure with a solid content rate of 28.6% is directly put into the thermal hydrolysis tank for dry low-temperature thermal hydrolysis, the heating temperature is 70°C, and the solid residence time is 3 days; the feces after dry low-temperature thermal hydrolysis After diluting to a solid content rate of 13.7%, carry out anaerobic digestion, the reaction temperature is 37 ° C, the solid residence time is 18 days, and the methane yield is 296.3 mL / g (as CH 4 / VS), which is 55.9% higher than that of raw manure.

Embodiment 3

[0019] Example 3: Cow dung with a solid content of 25.2% is directly put into the thermal hydrolysis tank for dry low-temperature thermal hydrolysis, the heating temperature is 70°C, and the solid residence time is 3 days; the feces after dry low-temperature thermal hydrolysis After diluting to a solid content rate of 14.8%, carry out anaerobic digestion, the reaction temperature is 58 ° C, the solid residence time is 14 days, and the methane yield is 309.2 mL / g (as CH 4 / VS), which is 82.7% higher than that of raw manure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com