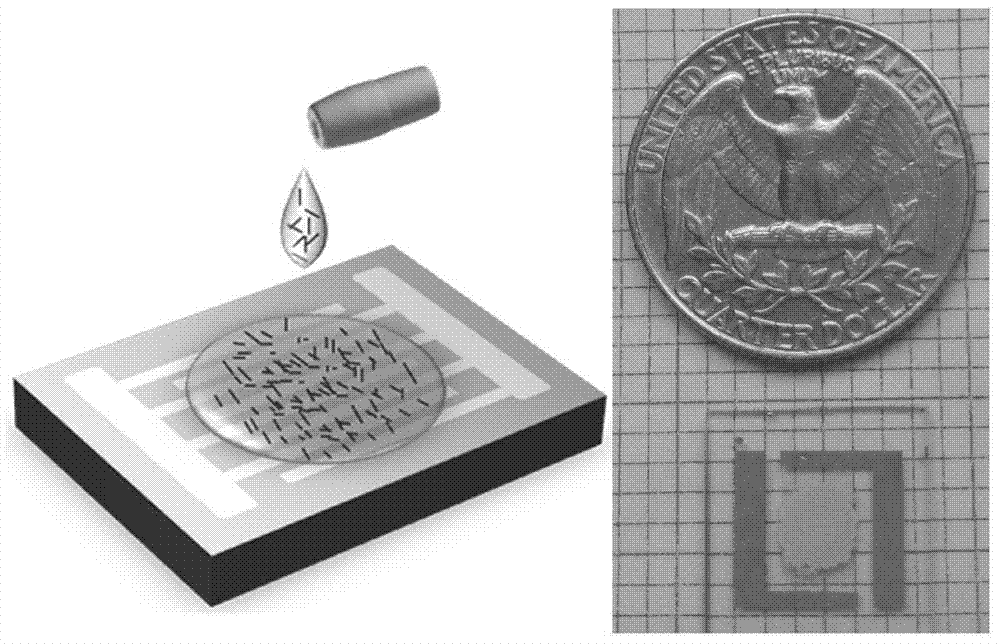

Molybdenum oxide nanobelt/graphene composite material and application of composite material in aspect of preparation of hydrogen-sensitive element

A technology of composite materials and sensitive components, applied in the direction of nanotechnology, nanotechnology, material resistance, etc., can solve the problems of repeatability and poor reliability, and achieve the effects of high controllability, short preparation cycle and high output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

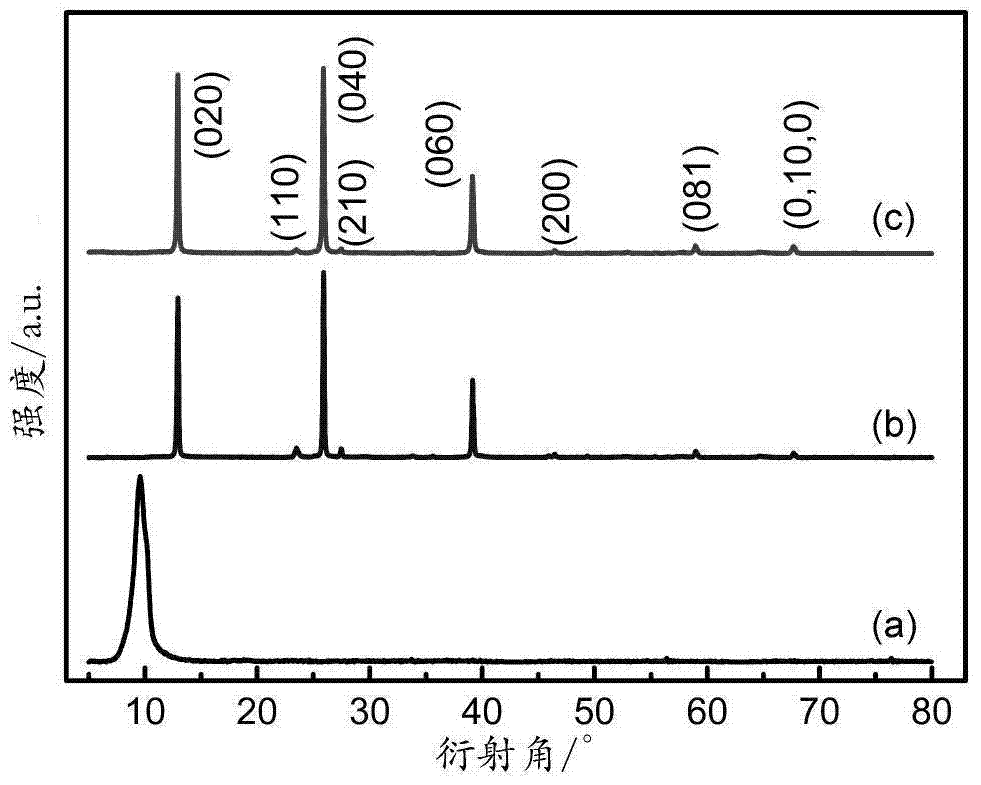

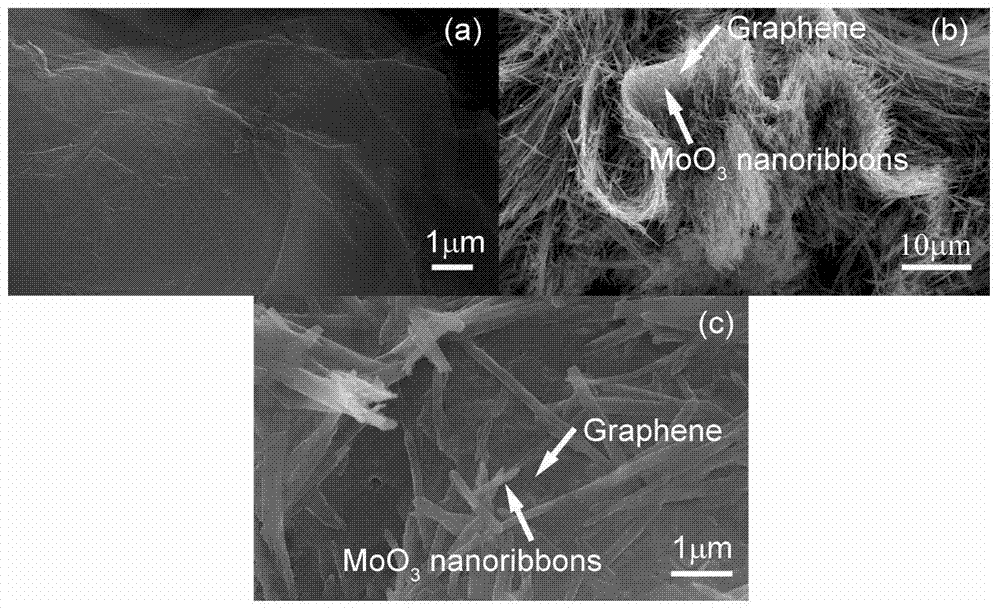

[0047] A preparation method of molybdenum oxide nanobelt / graphene composite material, comprising the steps of:

[0048] Step A: Preparation of Graphene Oxide

[0049] a1) Weigh 3.0g of graphite powder and 18.0g of potassium permanganate into a 1000ml beaker, stir for 10min with a glass rod, and mix well to obtain a solid mixed powder;

[0050] a2) Measure 360ml of concentrated sulfuric acid with a mass fraction of 98% and 40ml of concentrated phosphoric acid with a mass fraction of 65%, respectively, and add them to the beaker containing the solid mixed powder as described in step a1), stir magnetically for 30 minutes, and mix well to obtain a mixed liquid;

[0051] a3) Put the beaker containing the mixed liquid described in step a2) into a 50°C water bath, continue to stir, and keep warm for 12 hours to obtain a viscous liquid mixed product;

[0052] a4) Mix 10ml of hydrogen peroxide with a mass fraction of 30% and 500ml of distilled water respectively, then magnetically st...

Embodiment 2

[0076] A preparation method of molybdenum oxide nanobelt / graphene composite material, comprising the steps of:

[0077] Step A: Preparation of Graphene Oxide

[0078] Graphene oxide adopts the graphene oxide prepared by embodiment 1;

[0079] Step B: Preparation of molybdenum oxide nanoribbons / graphene composites

[0080] b1) In a 50ml reaction container, measure 0.75ml of the graphene oxide dispersion prepared in step A, measure 33ml of deionized water, stir and disperse evenly, and obtain a diluted dispersion;

[0081] b2) Slowly add 6.25ml of concentrated nitric acid with a mass fraction of 65% to the diluted dispersion obtained in step b1), continue to stir and mix evenly to obtain a mixed acid solution, the concentration of nitric acid in the mixed acid solution is 2.5mol / L ;

[0082] b3) Add 2.4195g of sodium molybdate (Na 2 MoO 4 2H 2 O), stirring slowly to fully dissolve the sodium molybdate, mixing evenly to obtain a mixed reaction solution, the concentration of...

Embodiment 3

[0097] A preparation method of molybdenum oxide nanobelt / graphene composite material, comprising the steps of:

[0098] Step A: Preparation of Graphene Oxide

[0099] Graphene oxide adopts the graphene oxide prepared in embodiment 1.

[0100] Step B: Preparation of molybdenum oxide nanoribbons / graphene composites

[0101] b1) In a 50ml reaction vessel, measure 0.5ml of the graphene oxide dispersion prepared in step A, measure 33.25ml of deionized water, stir and disperse evenly to obtain a diluted dispersion;

[0102] b2) Slowly add 6.25ml of concentrated nitric acid with a mass fraction of 65% to the diluted dispersion obtained in step b1), continue to stir and mix evenly to obtain a mixed acid solution, the concentration of nitric acid in the mixed acid solution is 2.5mol / L ;

[0103] b3) Add 2.4195g of sodium molybdate (Na 2 MoO 4 2H 2 O), stirring slowly to fully dissolve the sodium molybdate, mixing evenly to obtain a mixed reaction solution, the concentration of mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com