A probiotic and a processing method thereof

A processing method and technology of prebiotics, applied in the field of prebiotics and its processing, to achieve the effects of improved moisture absorption and heat resistance, improved heat resistance, and convenient storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Melting: Add isomaltooligosaccharide 90 powder into pure water at 45°C, stir and dissolve to make the concentration reach 80%.

[0033] (2) Add trehalose and stir: Add trehalose that has completely melted, stir and mix at 45°C for 60 minutes.

[0034] (3) Homogenization treatment: High-pressure homogenization treatment is carried out by a high-pressure homogenizer at a pressure of 40 mpa, so that the isomalto-oligosaccharide and trehalose form a fully uniform emulsion.

[0035] (4) Centrifugal spray drying: The homogenized emulsion is dried by a centrifugal spray dryer at a drying temperature of 160°C and a drying time of 20 seconds to obtain 90 powder microcapsules of isomaltooligosaccharide with a moisture content of less than 6%.

[0036] (5) Packing: Use polyethylene edible plastic bags to pack into different specifications of 0.1-25kg, and heat seal the bags.

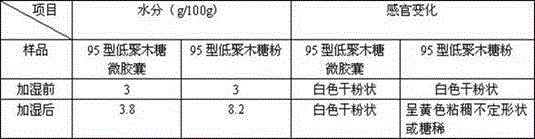

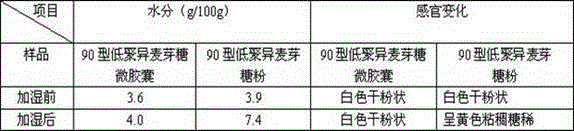

[0037]After the microencapsulated isomaltooligosaccharide granules are made, the moisture absorption...

Embodiment 2

[0042] Pure aqueous solution of isomalto-oligosaccharide and fructo-oligosaccharide syrup, trehalose and sodium starch octenyl succinate----keep warm and stir to dissolve----high pressure homogenization----vacuum belt drying----micro Encapsulated Compound Prebiotics----Packaging

[0043] (1) Syrup mixing: Stir and heat isomalto-oligosaccharide and fructo-oligosaccharide syrup in a hot and cold tank to 80°C to make them fully mixed.

[0044] (2) Adding trehalose and sodium starch octenyl succinate: Add the completely dissolved aqueous solution of trehalose and sodium starch octenyl succinate, and stir and mix at 80°C for 30 minutes.

[0045] (3) Homogenization treatment: High-pressure homogenization treatment is carried out by a high-pressure homogenizer at a pressure of 25mpa to form a fully uniform emulsion.

[0046] (4) Vacuum belt drying: The homogenized emulsion is dried by a vacuum bag dryer at a drying temperature of 100°C, a vacuum of 50-80 KPa, a drying time of 30 min...

Embodiment 3

[0053] The difference between embodiment 5 and embodiment 1 is that the selection of core material and wall material is different, and the proportion of core material and wall material in raw materials is different. Other production processes and technical indicators are basically the same. A prebiotic, specifically isomaltooligosaccharide, is used in an amount of 50%, and trehalose is used as a packaging material, and the amount used is 50%, that is, core material: wall material = 1:1.

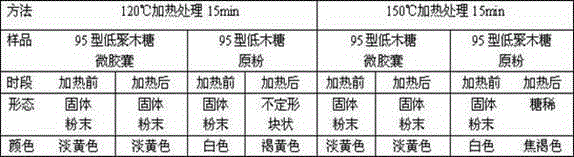

[0054] In the foregoing embodiments, commonly used prebiotics: such as fructo-oligosaccharides, xylo-oligosaccharides, isomalto-oligosaccharides, lactulose, inulin, polydextrose, breast milk oligosaccharides, and galacto-oligosaccharides are easy to absorb moisture and are intolerant Thermal prebiotics, after embedding treatment, have significantly reduced hygroscopicity and significantly increased heat resistance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com