Preparation method of composite antibacterial dressing loaded with silver sulfadiazine

A silver sulfadiazine and compound antibacterial technology, which is applied in the field of biomedical materials, can solve the problems of unfavorable wound healing, uneven application, easy pollution and deterioration, etc., and achieve a good humid environment, avoid secondary trauma, and good biocompatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

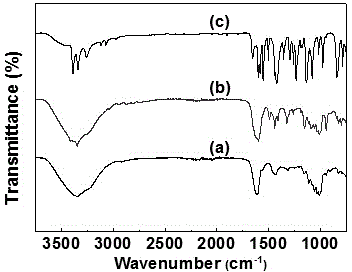

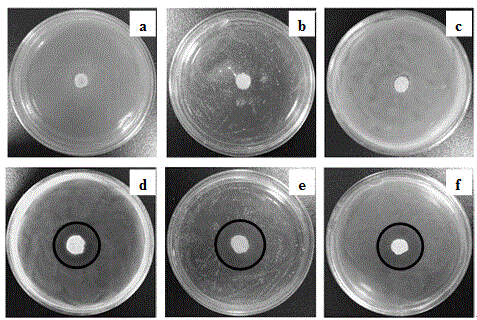

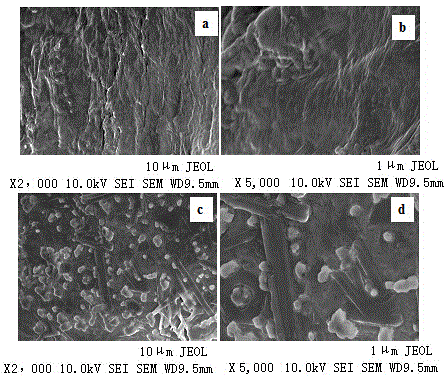

Image

Examples

Embodiment 1

[0034]Prepare 100 mL of seed culture with yeast extract (5 g / L), glucose (5 g / L), potassium dihydrogen phosphate (1 g / L), magnesium sulfate heptahydrate (15 g / L) and peptone (5 g / L) respectively base and 200mL of fermentation medium without adjusting the pH. Put the seed medium and fermentation medium into a sterilizing pot at a temperature of 121°C and a pressure of 0.1MPa, and sterilize for 20 minutes. After the culture medium is cooled, add ethanol (20mL / L). The activated Acetobacter xylinum was inoculated into the seed medium, and cultured in a shaker at 30° C. and 160 rpm / min for 24 h. According to the inoculum amount of 6% (volume ratio, within the range of 5-10%), inoculate the seed culture solution into the fermentation medium and shake it well to mix it evenly, and then culture it statically at 30±2°C for 1-2 weeks. A milky white bacterial cellulose film was obtained. Rinse the residues on the surface of bacterial cellulose with deionized water, soak in 0.1M NaOH so...

Embodiment 2

[0036] The method is the same as in Example 1, the difference is that the bacterial cellulose homogeneous suspension and sodium alginate solution are mixed with a mass ratio of 1:1 to generate a gel, then stirred evenly with silver sulfadiazine, then ultrasonically degassed, and solidified , and finally freeze-dried in vacuum at -80°C to obtain a silver-sulfadiazine-loaded composite antibacterial dressing.

Embodiment 3

[0038] The method is the same as in Example 1, the only difference is that 0.8mg silver sulfadiazine is added to the mixed gel of 5g bacterial cellulose and sodium alginate, the weight ratio of silver sulfadiazine is 0.016%, after stirring evenly, ultrasonic degassing Processing, solidification, and finally vacuum freeze-drying at -80°C to obtain a silver sulfadiazine-loaded composite antibacterial dressing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com