Method for performing electrolytic treatment on high-concentration ammonia nitrogen wastewater by using three-dimensional electrodes

A three-dimensional electrode, ammonia nitrogen wastewater technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of high purification efficiency of catalytic oxidation method, secondary pollution of stripping gas, Ammonia nitrogen removal efficiency is low and other problems, to overcome the effect of small effective area, improve removal rate, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

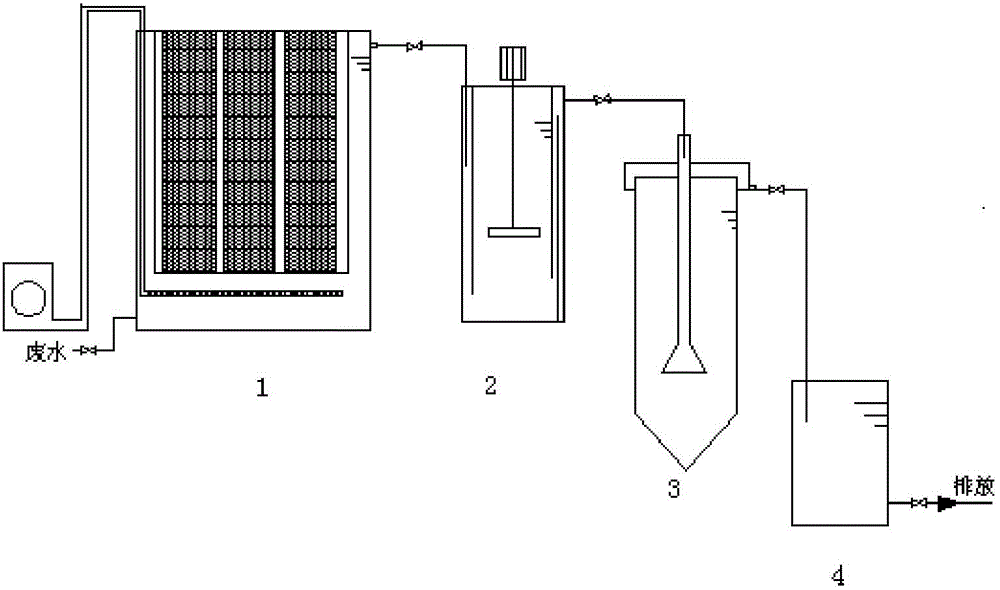

[0025] A method for electrolytically treating high-concentration ammonia-nitrogen wastewater with a three-dimensional electrode of the present invention is used for certain high-ammonia-nitrogen wastewater. NH 3 -N 2000~3000mg / L, pH 0.82. First, three-dimensional electrode electrolytic treatment is carried out, the anode is titanium-plated steel plate, the cathode is steel plate, the particle electrode particles are iron-based catalysts, the size is 2.0cm, the filling amount is 75%, and the reaction is 2h. At this time, the wastewater after three-dimensional electrode electrolytic treatment NH 3 -N 51 mg / L, pH 4.5. The wastewater treated by three-dimensional electrode electrolysis undergoes flocculation reaction, adding sodium hydroxide to adjust the pH of the wastewater to 9, and reacting for 15 minutes. At this time, the wastewater NH after flocculation treatment 3 -N 25mg / L. After the flocculation reaction and dosing, the wastewater enters the vertical flow reaction sed...

Embodiment 2

[0027] A method for electrolytically treating high-concentration ammonia-nitrogen wastewater with a three-dimensional electrode of the present invention is used for certain high-ammonia-nitrogen wastewater. NH 3 -N 2000~3000mg / L, pH 0.65. First, three-dimensional electrode electrolytic treatment is carried out, the anode is titanium-plated steel plate, the cathode is steel plate, the particle electrode particles are iron-based catalysts, the size is 2.0cm, the filling amount is 75%, and the reaction is 2h. At this time, the wastewater after three-dimensional electrode electrolytic treatment NH 3 -N 51 mg / L, pH 4.8. The wastewater treated by three-dimensional electrode electrolysis undergoes flocculation reaction, adding sodium hydroxide to adjust the pH of the wastewater to 9, and reacting for 15 minutes. At this time, the wastewater NH after flocculation treatment 3 -N 20mg / L. After the flocculation reaction and dosing, the wastewater enters the vertical flow reaction sed...

Embodiment 3

[0029] A method for treating high-concentration ammonia-nitrogen wastewater by three-dimensional electrolysis of the present invention is used for certain high-ammonia-nitrogen wastewater. NH 3 -N 2000~3000mg / L, pH 0.78. First, three-dimensional electrode electrolytic treatment is carried out, the anode is titanium-plated steel plate, the cathode is steel plate, the particle electrode particles are iron-based catalysts, the size is 2.0cm, the filling amount is 75%, and the reaction is 2h. At this time, the wastewater after three-dimensional electrode electrolytic treatment NH 3 -N 51 mg / L, pH 5.2. The wastewater treated by three-dimensional electrode electrolysis undergoes flocculation reaction, adding sodium hydroxide to adjust the pH of the wastewater to 9, and reacting for 15 minutes. At this time, the wastewater NH after flocculation treatment 3 -N 21mg / L. After the flocculation reaction and dosing, the wastewater enters the vertical flow reaction sedimentation tank fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com