A kind of preparation method of modified polypropylene composite toughening material

A composite toughening material, polypropylene technology, applied in the field of polypropylene, can solve the problems of poor impact resistance and poor polypropylene toughness, and achieve the effect of increasing synergy, improving impact resistance, and improving modulus and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

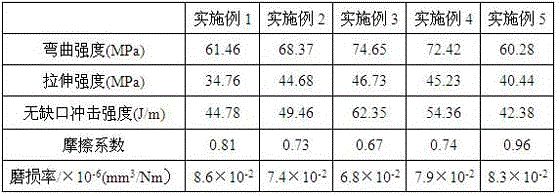

Examples

Embodiment 1

[0023] A method for preparing a modified polypropylene composite toughening material, comprising the following steps: step 1, taking water glass and an aqueous solution of ammonium pentaborate with a mass fraction of 10% according to a weight ratio of 1:1, mixing and stirring uniformly to obtain a mixed solution ,spare;

[0024] Step 2. Weigh the vulcanized rubber powder and the mixed solution prepared in step 1 according to the weight ratio of 1:2, and spray the vulcanized rubber powder and the mixed solution prepared in step 1 into the spray drying tower respectively to obtain microbeads. The beads are dried in a dryer at 300°C to obtain glass bead fillers for later use; wherein, the injection directions of the vulcanized rubber powder and the mixed solution are set oppositely; the inlet temperature of the drying tower is 420°C, and the outlet temperature is 160°C;

[0025] Step 3: Weigh the microcapsule powder, kaolin powder and absolute ethanol according to the weight rati...

Embodiment 2

[0032] A method for preparing a modified polypropylene composite toughening material, comprising the following steps: step 1, taking water glass and an aqueous solution of ammonium pentaborate with a mass fraction of 10% according to a weight ratio of 1:1, mixing and stirring uniformly to obtain a mixed solution ,spare;

[0033] Step 2. Weigh the vulcanized rubber powder and the mixed solution prepared in step 1 according to the weight ratio of 1:2, and spray the vulcanized rubber powder and the mixed solution prepared in step 1 into the spray drying tower respectively to obtain microbeads. The beads are dried in a dryer at 300°C to obtain glass microbead fillers for later use; wherein, the injection directions of the vulcanized rubber powder and the mixed solution are set opposite to each other; the inlet temperature of the drying tower is 400°C, and the outlet temperature is 150°C;

[0034] Step 3. Weigh the microcapsule powder, kaolin powder and absolute ethanol according t...

Embodiment 3

[0040] A method for preparing a modified polypropylene composite toughening material, comprising the following steps: firstly, according to the method of step 1 and step 2 of Example 2, glass microsphere fillers are prepared for use; secondly, according to who 2, step 3 and The method of step 4 is to prepare kaolin microcapsule powder for future use; thirdly, mix the silane coupling agent and potassium hexatitanate whiskers in a weight ratio of 2:100 to prepare whisker reinforcing materials for future use; fourth , take by weighing 70% polypropylene matrix, 4% maleic anhydride grafted polypropylene, 0.5% phosphite antioxidant and 1.5% simethicone oil respectively, according to the conditions of embodiment 2 step 6, prepare The mixture pellets are obtained for subsequent use; the 5th, the mixture pellets are added in the two-roll mill, the front roller temperature of the two-roll mill is set to 180°C, and the rear roller temperature is set to 175°C, and the mixture pellets are c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com