Preparation method of functional additive-containing lithium ion battery

A technology of lithium-ion batteries and additives, applied in battery electrodes, secondary batteries, circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

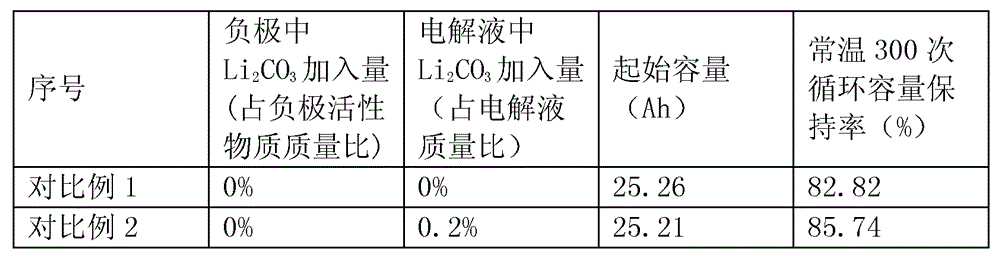

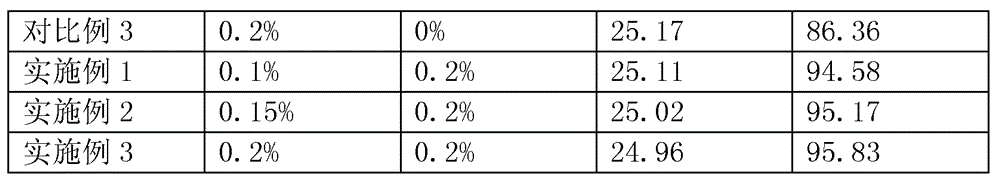

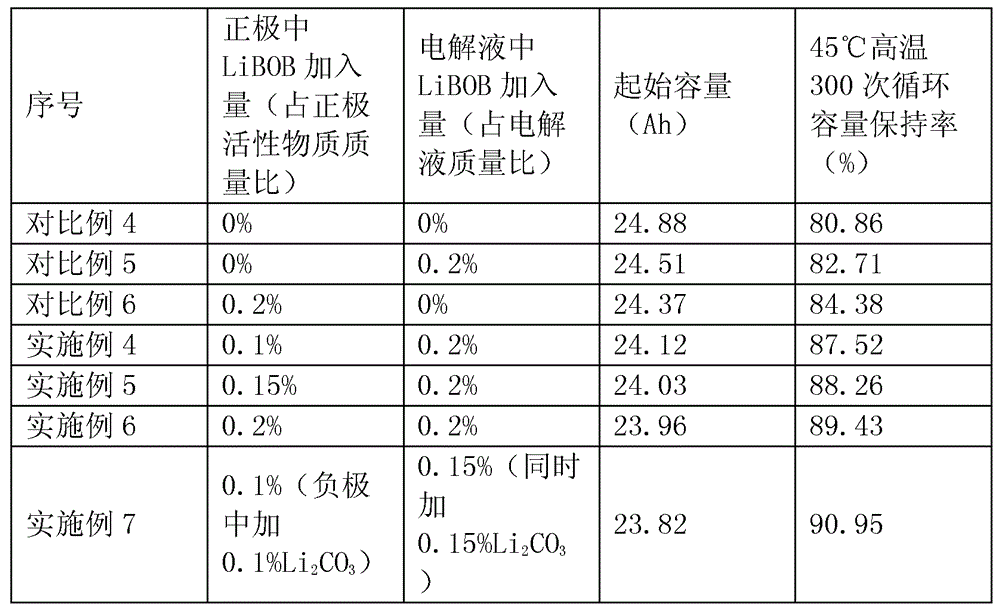

Embodiment 1

[0026] Negative electrode preparation: will be 0.1% lithium carbonate (Li 2 CO 3 ) Add additives to cellulose sodium (CMC) aqueous solution (hereinafter referred to as negative electrode glue), stir evenly, then add conductive agent, active material graphite, and binder in a certain proportion, stir evenly to form a slurry, and then coat to obtain negative electrode .

[0027] Positive electrode preparation: Conductive agent, positive electrode active material nickel cobalt lithium manganese oxide Li (Ni 0.5 co 0.2 mn 0.3 )O 2 Adding in a certain proportion to an N-methylpyrrolidone (NMP) solution containing a binder, uniformly stirring to obtain a positive electrode slurry, and then coating to obtain a positive electrode.

[0028] Electrolyte preparation: The electrolyte is dissolved lithium hexafluorophosphate (LiPF 6 ) of ethylene carbonate-ethyl methyl carbonate (EC-EMC) mixed solution, in which adding 0.2% Li with respect to the electrolyte mass ratio 2 CO 3 addit...

Embodiment 2

[0031]The steps of embodiment 2 are basically the same as in embodiment 1, except that the Li 2 CO 3 The mass ratio of additives relative to the active substance is 0.15%.

Embodiment 3

[0033] The steps of Example 3 are basically the same as in Example 1, except that the Li in the negative electrode glue is added 2 CO 3 The mass ratio of additives relative to the active substance is 0.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com