Preparation method of pyraclostrobin microcapsules

A technology of pyraclostrobin and microcapsules, which is applied in the field of pesticides, can solve the problems that the drug effect is difficult to last to the plants, the duration of the effect is short, and the workload is heavy, so as to reduce the number of application times, improve the safety, and improve the production process. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

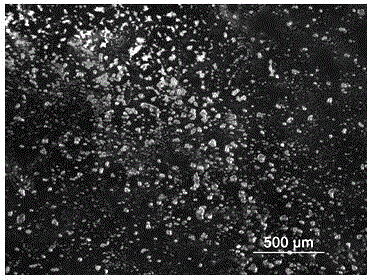

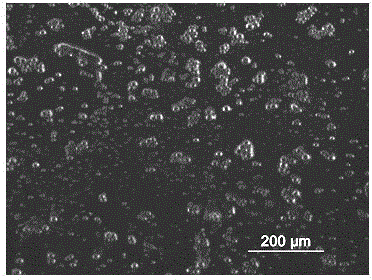

Image

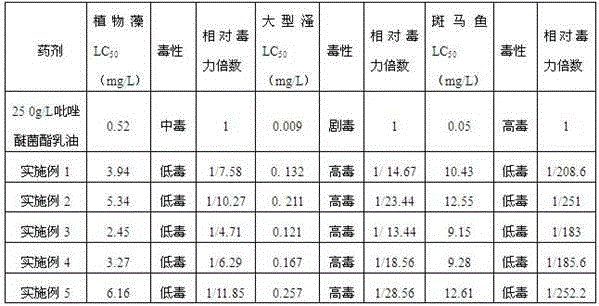

Examples

Embodiment 1

[0034] The preparation method of 25% pyraclostrobin microcapsule suspension comprises steps:

[0035] 1) Add 26.32 g of 95% pyraclostrobin technical substance into 10 g of xylene to fully dissolve, then add 3.15 g of toluene diisocyanate and 1.55 g of PEG 600, stir well, and use it as the oil phase;

[0036] 2) 0.2 g tristyrylphenol polyoxyethylene ether (emulsifier), 3 g calcium lignosulfonate (dispersant) and 0.1 g polyvinyl alcohol (colloidal protective agent) were uniformly mixed with 53.54 g water as the water phase;

[0037] 3) The oil phase is mixed with the water phase, and sheared and emulsified by a high-speed homogenizer to obtain a stable O / W emulsion;

[0038] 4) Transfer the O / W emulsion to a flask, stir at a speed of 200 rpm, raise the temperature to 65°C, react for 4 hours, adjust the pH value to 6-6.5 with citric acid; add 2 g of ethylene glycol, 0.14 g The xanthan gum was evenly stirred to obtain 25% pyraclostrobin microcapsule suspension.

Embodiment 2

[0039] Embodiment 2, embodiment 3, embodiment 4 respectively change " toluene diisocyanate " in embodiment 1 into " diphenylmethane diisocyanate ", " isophorone diisocyanate " and " hexamethylene diisocyanate ", other unchanged, prepare 25% pyraclostrobin microcapsule suspension respectively.

[0040] The pyraclostrobin microcapsule suspension prepared in Example 2 has an encapsulation rate ≥ 93%, a particle size range of 0.4-15 μm, a suspension rate ≥ 92%, persistent foaming (after 1 min) ≤ 20 mL, and a pH value of 6.0 -6.5, heat storage and freeze-thaw stability qualified.

Embodiment 5

[0042]The preparation method of 10% pyraclostrobin microcapsules water-dispersible granules, the steps are:

[0043] 1) Add 42.11 g of 95% pyraclostrobin technical substance into 16 g of xylene to fully dissolve, then add 3.55 g of diphenylmethane diisocyanate and 1.25 g of PEG 1000, stir well, and use it as the oil phase;

[0044] 2) 0.50g of fatty alcohol polyoxyethylene ether (emulsifier), 3g of sodium lignosulfonate (dispersant) and 0.1g of polyvinyl alcohol (colloidal protective agent) are uniformly mixed with 55g of water as the water phase;

[0045] 3) The oil phase is mixed with the water phase, and sheared and emulsified by a high-speed homogenizer to obtain a stable O / W emulsion;

[0046] 4) Transfer the O / W emulsion to a flask, stir at a speed of 200 rpm, heat up to 65°C, react for 4 hours, adjust the pH value to 6-6.5 with acetic acid, mix with 286.69g kaolin, 32g lignosulfonic acid Calcium, 8g NNO, 4g sodium lauryl sulfate and 4g ammonium chloride were uniformly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com