Simple preparation method for one-piece high load copper base catalyst

A copper-based catalyst and high-loading technology, which is applied in the preparation of hydroxyl compounds, chemical instruments and methods, and the preparation of organic compounds. Weak carrier interaction, affecting the hydrogenation activity life of the catalyst, etc., to achieve the effect of improving stability and service life, more active sites, and higher loading capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

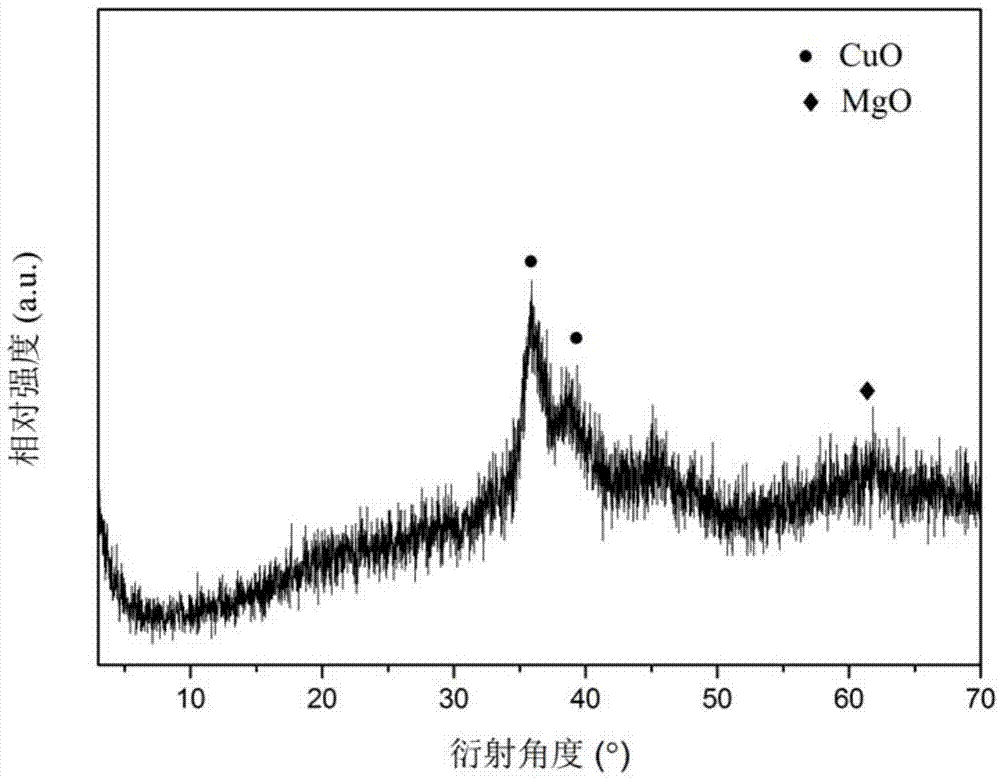

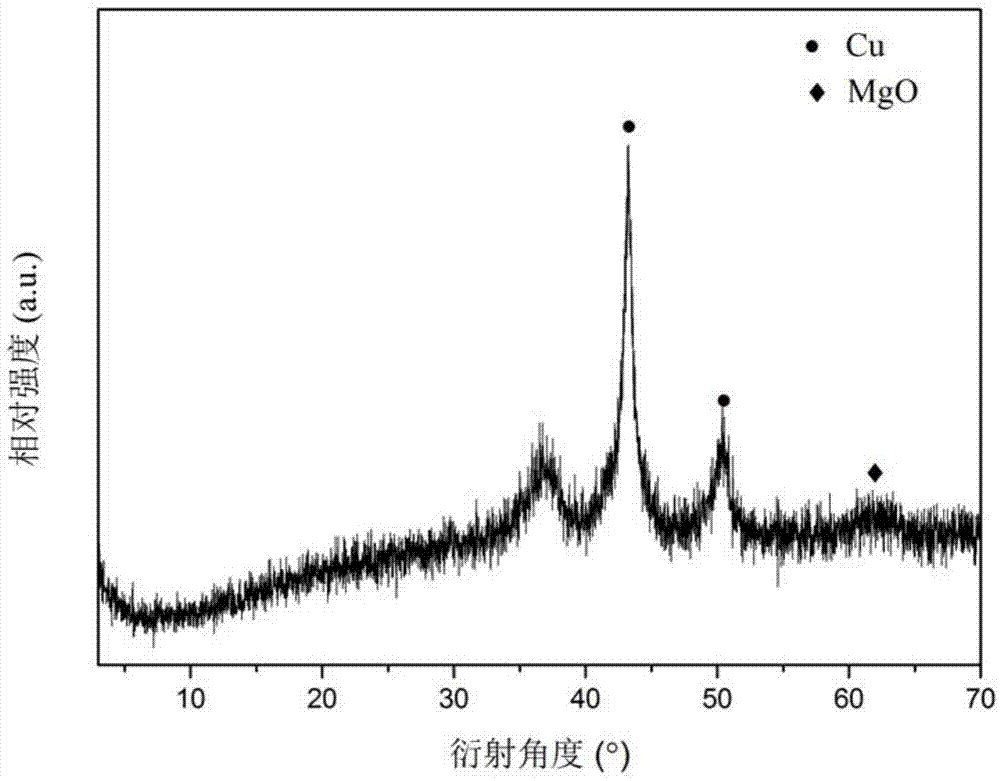

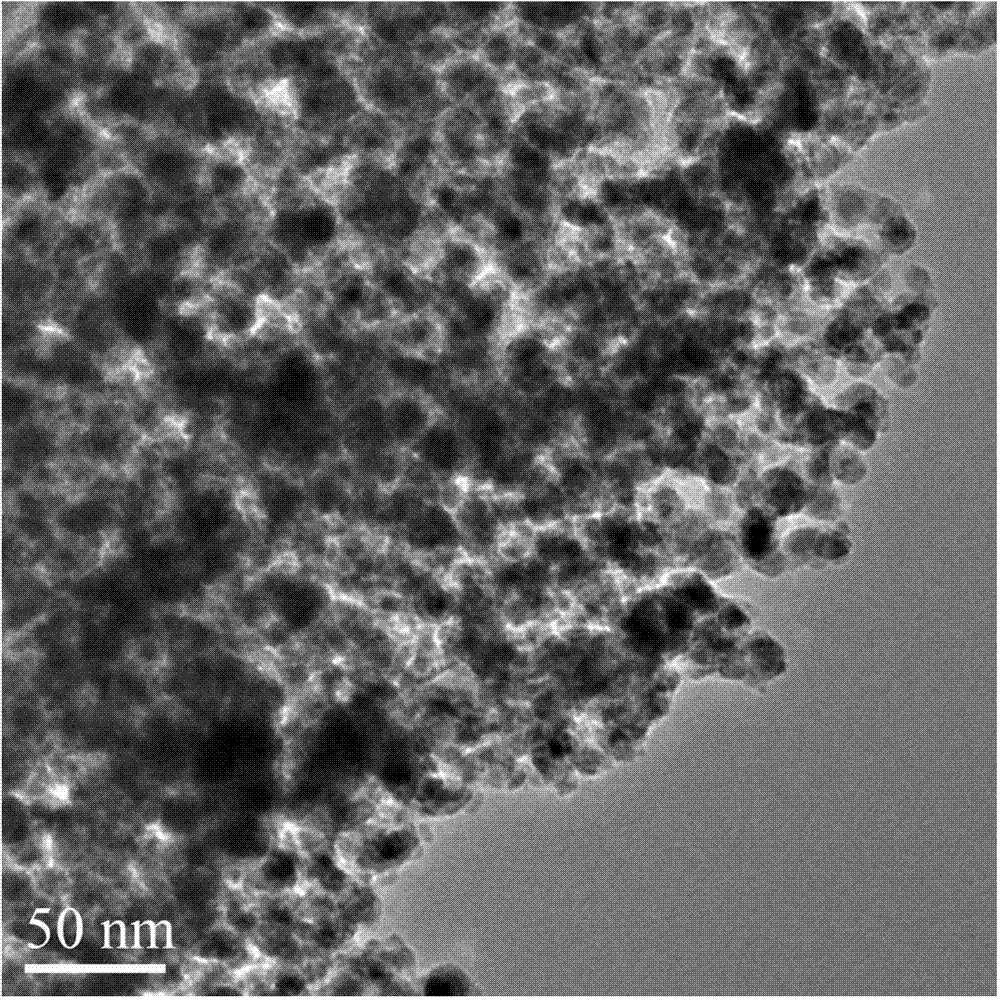

[0022] Accurately weigh Cu(NO 3 ) 2 ·6H 2 O, Mg(NO 3 ) 2 ·6H 2 O is prepared into a mixed salt solution with deionized water, and Cu in the solution 2+ The molar concentration is 0.5mol / L, Mg 2+ The molar concentration is 0.3mol / L. Sodium hydroxide and sodium carbonate were dissolved in deionized water to prepare a mixed alkaline solution, wherein the molar concentration of sodium hydroxide was 0.8 mol / L, and the molar concentration of sodium carbonate was 0.4 mol / L. Pour an equal volume of 100ml mixed salt solution and mixed alkaline solution into the colloid mill at the same time, stir at a speed of 3000 rpm for 8 minutes, then wash with deionized water for 5 times, and then add it to a 500ml three-necked bottle together with 250ml water crystallized at 70°C for 12 hours, and then cooled to room temperature naturally. After filtration, washing, and drying at 60°C for 18 hours to obtain hydroxide nanoparticles, the prepared catalyst precursor was placed in a muffle fu...

Embodiment 2

[0025] Accurately weigh Cu(NO 3 ) 2 ·6H 2 O, Mg(NO 3 ) 2 ·6H 2 O, prepare mixed salt solution with deionized water, Cu in the solution 2+ The molar concentration is 0.55mol / L, Mg 2+The molar concentration is 0.25mol / L. Dissolve sodium hydroxide and sodium sodium carbonate in deionized water to prepare a mixed alkaline solution, wherein the molar concentration of sodium hydroxide is 0.90 mol / L, and the molar concentration of sodium carbonate is 0.45 mol / L. Pour an equal volume of 100ml mixed salt solution and mixed alkaline solution into the colloid mill at the same time, stir at a speed of 5000 rpm for 6 minutes, then wash with deionized water for 4 times, and then add it to a 500ml three-necked bottle together with 250ml water crystallized at 70°C for 24 hours, and then cooled to room temperature naturally. After filtering, washing, and drying at 90°C for 30 hours to obtain hydroxide nanoparticles, the prepared catalyst precursor was placed in a muffle furnace, and th...

Embodiment 3

[0028] Accurately weigh Cu(NO 3 ) 2 ·6H 2 O, Mg(NO 3 ) 2 ·6H 2 O, prepare mixed salt solution with deionized water, Cu in the solution 2+ The molar concentration is 0.6mol / L, Mg 2+ The molar concentration is 0.2mol / L. Dissolve sodium hydroxide and sodium carbonate in deionized water to prepare a mixed alkaline solution, wherein the molar concentration of sodium hydroxide is 1.0 mol / L, and the molar concentration of sodium carbonate is 0.5 mol / L. Pour an equal volume of 100ml mixed salt solution and mixed alkaline solution into the colloid mill at the same time, stir at a speed of 6000 rpm for 10 minutes, then wash with deionized water for 3 times, and then add it to a 500ml three-necked bottle together with 250ml water crystallized at 80°C for 48 hours, and then cooled to room temperature naturally. After filtering, washing, and drying at 100°C for 24 hours to obtain hydroxide nanoparticles, the prepared catalyst precursor was placed in a muffle furnace, and the temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com