Process for synthesizing biurea by adopting semicarbazide

A semicarbazide and biuret technology, applied in the field of biuret synthesis, can solve the problems of low utilization rate of raw materials, low product yield, long reaction time, etc., and achieve the effects of low acidity, high conversion rate and little equipment corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

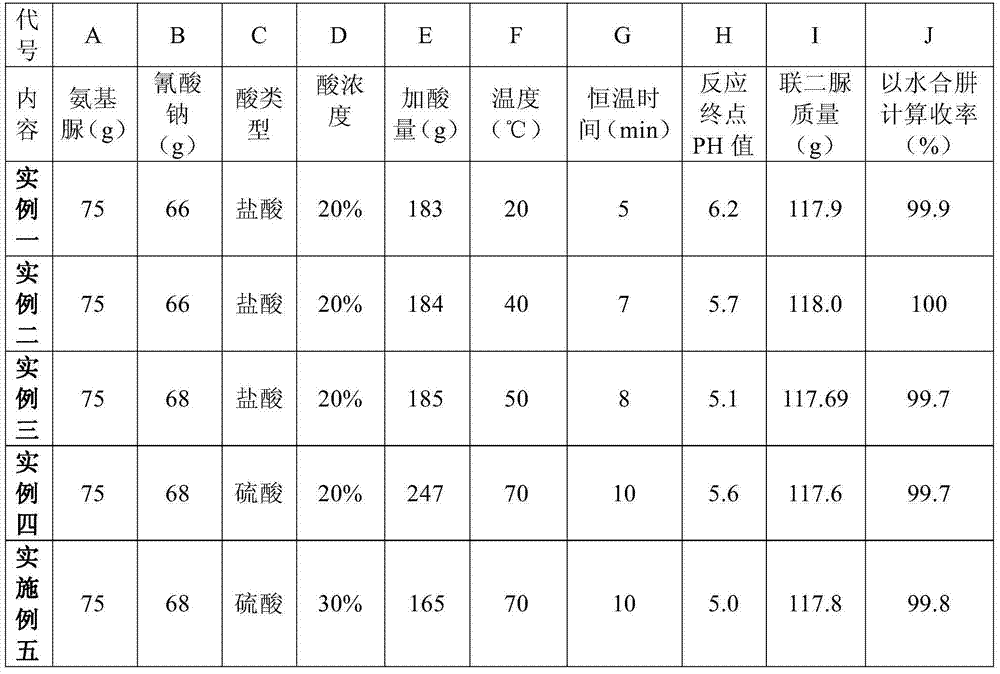

Examples

Embodiment 1

[0031] First weigh 75g of semicarbazide, then weigh 66g of sodium cyanate, add both into a three-necked flask filled with 200mL of water, stir until the solution is clear, keep the solution temperature at 20°C, weigh 183g of 20% hydrochloric acid solution drop by drop Add it to the above mixture, stir while adding, and continue stirring for 5 minutes after the addition of hydrochloric acid is complete, then filter, wash and dry.

Embodiment 2

[0033] First weigh 75g of semicarbazide, then weigh 66g of sodium cyanate, add both into a three-necked flask filled with 200mL of water, stir until the solution is clear, keep the solution temperature at 40°C, weigh 184g of 20% hydrochloric acid solution drop by drop Add to the above mixture, stir while adding, and continue to stir for 7 minutes after the addition of hydrochloric acid is complete, then filter, wash and dry.

Embodiment 3

[0035] First weigh 75g of semicarbazide, then weigh 68g of sodium cyanate, add both into a three-necked flask filled with 200mL of water, stir until the solution is clear, keep the solution temperature at 50°C, weigh 185g of 20% hydrochloric acid solution drop by drop Add it to the above mixture, stir while adding, and continue stirring for 8 minutes after the addition of hydrochloric acid is complete, then filter, wash and dry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com