Steel shell of alkaline zinc-manganese battery and alkaline zinc-manganese battery

A technology of zinc-manganese batteries and steel shells, which is applied to battery pack parts, battery boxes/covers, and battery box/cover materials, etc., which can solve the problems of limited coverage density and protection ability, reduced battery storage power, and reduced adhesion, etc. problems, to achieve the effect of inhibiting battery performance degradation, inhibiting swelling and peeling, and increasing coverage density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

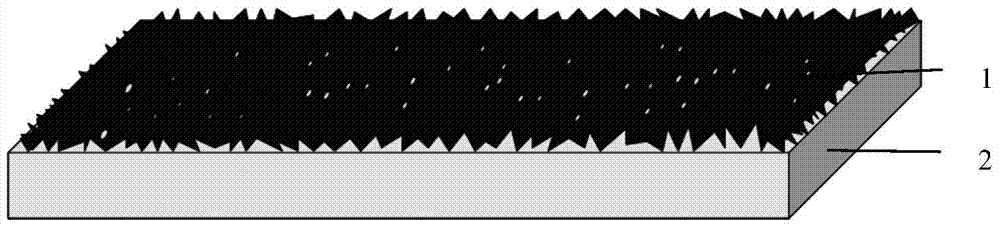

[0040] The steel casing of the alkaline zinc-manganese battery of the present invention is modified by a graphene coating, and its preparation method comprises the following steps:

[0041] a provide a steel shell;

[0042] Steel shells can be pre-nickel-plated steel shells or post-nickel-plated steel shells, which are punched from steel strips; the pre-nickel-plated steel shells are first punched with nickel-plated steel strips and then punched into fixed-shaped open steel shells and then passed through It is obtained by cleaning; after the nickel-plated steel shell is a wire, the steel strip is punched into an open steel shell with a fixed shape, and then it is obtained through degreasing, electroplating, and cleaning; It is sufficient to limit the purpose of the invention;

[0043] B uniformly disperse graphene, conventional conductive agent, binding agent and a small amount of additives such as stabilizer, neutralizer and defoamer in solvent to obtain mixed slurry;

[00...

Embodiment 1

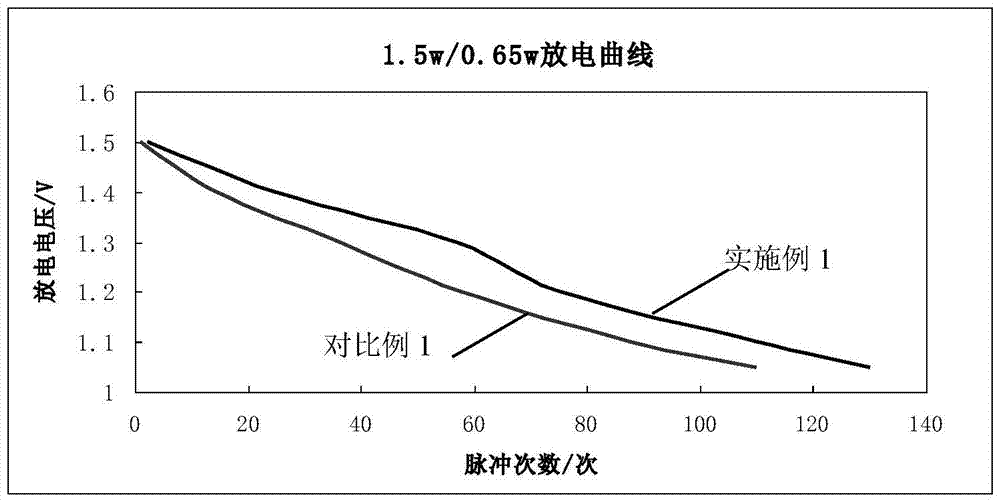

[0064] Obtain graphene material by graphite oxide reduction method, the thickness of graphene material is 10 nanometers, and specific surface area is 2500㎡ / g, and area is 0.01 micron, with 49wt% graphene, 50wt% carbon black, 1wt% CMC binding agent and A small amount of dispersant sodium dodecylsulfonate is dispersed in water, and the mixed slurry is obtained by ultrasonic dispersion; the above mixed slurry is sprayed and dried on the inner wall of the steel shell, and finally the alkalinity of the graphene-modified conductive coating is obtained. The steel case of the zinc-manganese battery, the graphene modified coating load of the steel case is 0.6mg / piece, and the thickness of the conductive coating is 1 micron; then insert the positive electrode ring into the steel case, insert the separator paper accordingly, and inject the zinc paste , insert the current collector composed of copper nails, negative electrode bottom and sealing ring, crimp and shape the seal to obtain the ...

Embodiment 2

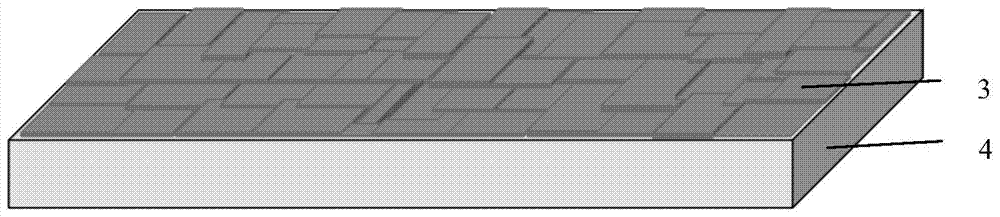

[0066] Obtain graphene material by physical method, the thickness of graphene material is 100 nanometers, and specific surface area is 10㎡ / g, and area is 10 microns, and 98wt% graphene, 1wt% acetylene black, 1wt% polyvinylidene fluoride binder And a small amount of dispersant sodium dodecylsulfonate is dispersed in water, and the mixed slurry is obtained through ultrasonic dispersion; the above mixed slurry is sprayed and dried on the inner wall of the steel shell, and finally the alkali of the graphene-modified conductive coating is obtained. The steel case of the non-toxic zinc-manganese battery, the thickness of the conductive coating is 20 microns; then the positive electrode ring is embedded in the steel case, and the separator paper is inserted accordingly, the zinc paste is injected, and the current collector composed of copper nails, negative electrode bottom and sealing ring is inserted. , crimping and shaping to get the LR6 battery. The test method is the same as in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com