Heat and corrosion resistant vacuum bottle with long service life

A corrosion-resistant, thermos bottle technology, applied in the direction of gas/liquid distribution and storage, fixed-capacity gas storage tanks, mechanical equipment, etc., can solve the problems of heat resistance and weak corrosion resistance, to increase corrosion resistance, improve resistance Thermal properties, effects of improving thermal oxygen resistance and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

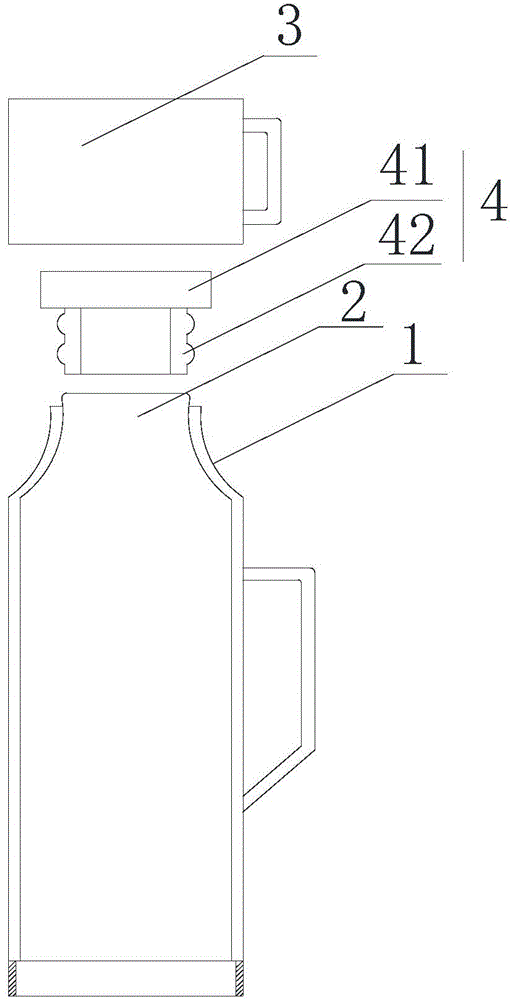

[0019] refer to figure 1 , a heat-resistant and corrosion-resistant thermos bottle with a long service life, including a bottle body 1, an inner tank 2, an upper cover assembly 3, and a heat preservation plug 4; the inner tank 2 is placed in the bottle body 1, and the upper cover assembly 3 is fastened to the bottle body 1 at the top, the insulation plug 4 is connected with the opening of the liner 2; wherein the insulation plug 4 includes a base 41 and a sealing sleeve 42, the sealing sleeve 42 is sealed and connected with the side wall of the base 41, and the sealing sleeve 42 is made of silicon rubber.

[0020] The raw materials of silicone rubber include by weight: 30 parts of methyl vinyl silicone oil, 4 parts of vinyl trimethoxysilane, 1 part of vinyl triethoxysilane, 1,3-divinyl dimethyl disiloxane 2 parts of alkanes, 0.5 parts of cyclic vinyl siloxane, 0.007 parts of titanium chelate, 0.0002 parts of dibutyltin dilaurate, 1.5 parts of phthalates, 1 part of isophthalate...

Embodiment 2

[0022] refer to figure 1 , a heat-resistant and corrosion-resistant thermos bottle with a long service life, including a bottle body 1, an inner tank 2, an upper cover assembly 3, and a heat preservation plug 4; the inner tank 2 is placed in the bottle body 1, and the upper cover assembly 3 is fastened to the bottle body 1 at the top, the insulation plug 4 is connected with the opening of the liner 2; wherein the insulation plug 4 includes a base 41 and a sealing sleeve 42, the sealing sleeve 42 is sealed and connected with the side wall of the base 41, and the sealing sleeve 42 is made of silicon rubber.

[0023] The raw materials of silicone rubber include by weight: 50 parts of methyl vinyl silicone oil, 2 parts of vinyl trimethoxysilane, 3 parts of vinyl triethoxysilane, 1,3-divinyl dimethyl disiloxane 1 part of alkanes, 1.5 parts of cyclic vinyl siloxane, 0.003 parts of titanium chelate, 0.0009 parts of dibutyltin dilaurate, 0.5 parts of phthalates, 3 parts of isophthalat...

Embodiment 3

[0025] refer to figure 1 , a heat-resistant and corrosion-resistant thermos bottle with a long service life, including a bottle body 1, an inner tank 2, an upper cover assembly 3, and a heat preservation plug 4; the inner tank 2 is placed in the bottle body 1, and the upper cover assembly 3 is fastened to the bottle body 1 at the top, the insulation plug 4 is connected with the opening of the liner 2; wherein the insulation plug 4 includes a base 41 and a sealing sleeve 42, the sealing sleeve 42 is sealed and connected with the side wall of the base 41, and the sealing sleeve 42 is made of silicon rubber.

[0026] The raw materials of silicone rubber include by weight: 40 parts of methyl vinyl silicone oil, 3.6 parts of vinyl trimethoxysilane, 2 parts of vinyl triethoxysilane, 1,3-divinyl dimethyl disiloxane 1.8 parts of alkanes, 1 part of cyclic vinyl siloxane, 0.006 parts of titanium chelate, 0.0005 parts of dibutyltin dilaurate, 1.3 parts of phthalates, 2 parts of isophthal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com