Probiotics double-layered microcapsule and manufacturing method thereof

A technology of microcapsules and probiotics, applied in the biological field, can solve the problems of easy water loss, bacterial cell death, etc., and achieve the effects of low cost of raw materials, good storage performance, and significant water loss resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] 1) Experimental method

[0053] Determine the level range of each factor through single factor experiment, and then pass L 9 (3 4 ) Orthogonal experiments to screen the best double-layer microcapsules. After obtaining the best formula, carry out property comprehensive experiments (simulating gastric acid resistance, enteric coating, storage experiments) and conduct comparisons to remove its properties;

[0054] Preparation of microcapsules: mix bacterial powder and wall material raw materials, add deionized water, and emulsify with 200Bar high pressure for 10 minutes. The resulting emulsion was quickly dropped into CaCl 2 The solution (solidified solution) was left to solidify for 20 minutes. Implant chitosan with CaCl after collecting washed capsules 2 The solution was formed into a film for 20 minutes, collected and washed again to obtain double-layer microcapsules;

[0055] (1) Single factor experiment of microcapsule preparation:

[0056] The experiment deter...

Embodiment 2

[0088] Embodiment 2 Effect experiment of each wall material on embedding rate

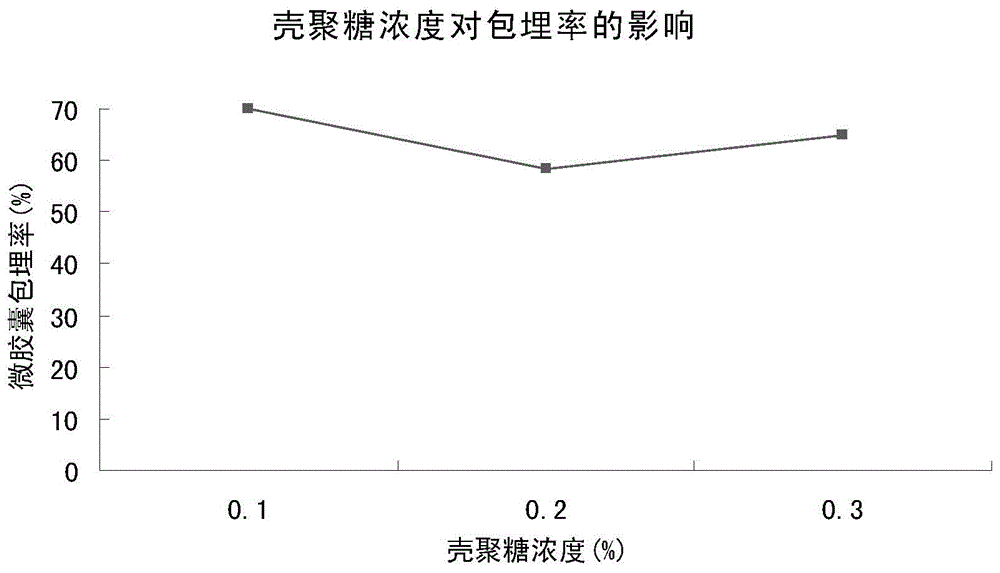

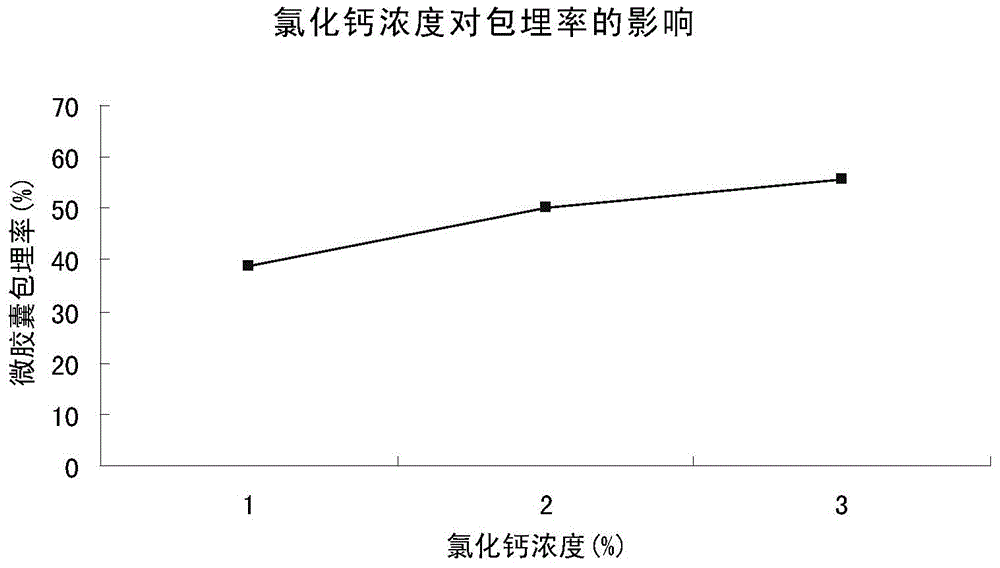

[0089] 1. Set each wall material separately for single factor experiment

[0090] In this experiment, the sodium alginate in the inner capsule is set as a constant: 2% sodium alginate, CaCl 2 2%, off

[0091] Fat milk powder 3%, lactose 4%, chitosan 0.2%;

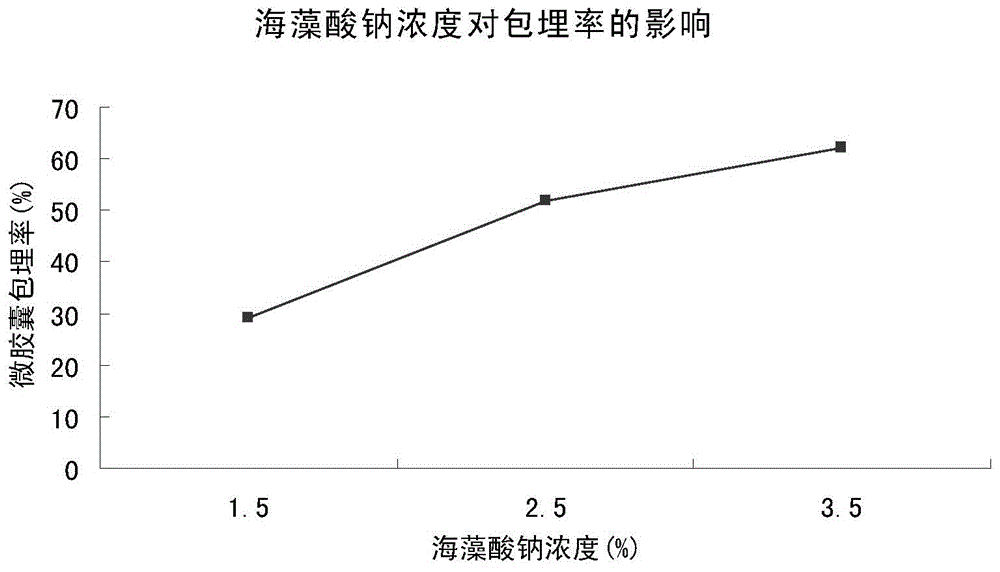

[0092]The results showed that: when the concentration of sodium alginate was too low, bacteria could not be effectively embedded, and the obtained capsules were soft, non-spherical, with tail-like structures, or even flocculent precipitates, which did not meet the experimental requirements. and when the concentration is too high, the viscosity of the bacteria emulsion is too high, homogenization is difficult, and the resulting capsule texture is too hard to be easily uncapsulated. During the orthogonal experiment in the present invention, the sodium alginate level is adjusted to: 2%, 2.5% , 3%;

[0093] Set sodium alginate as a variable: the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com