Preparation method of Cu nanoparticle-loaded ordered mesoporous carbon catalyst

A nanoparticle and catalyst technology, which is applied in the field of preparation of ordered mesoporous carbon-supported Cu nanoparticle catalysts, can solve the problems of grain growth, catalytic activity reduction, and catalytic activity decline, and achieve high activity, high reactivity, good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

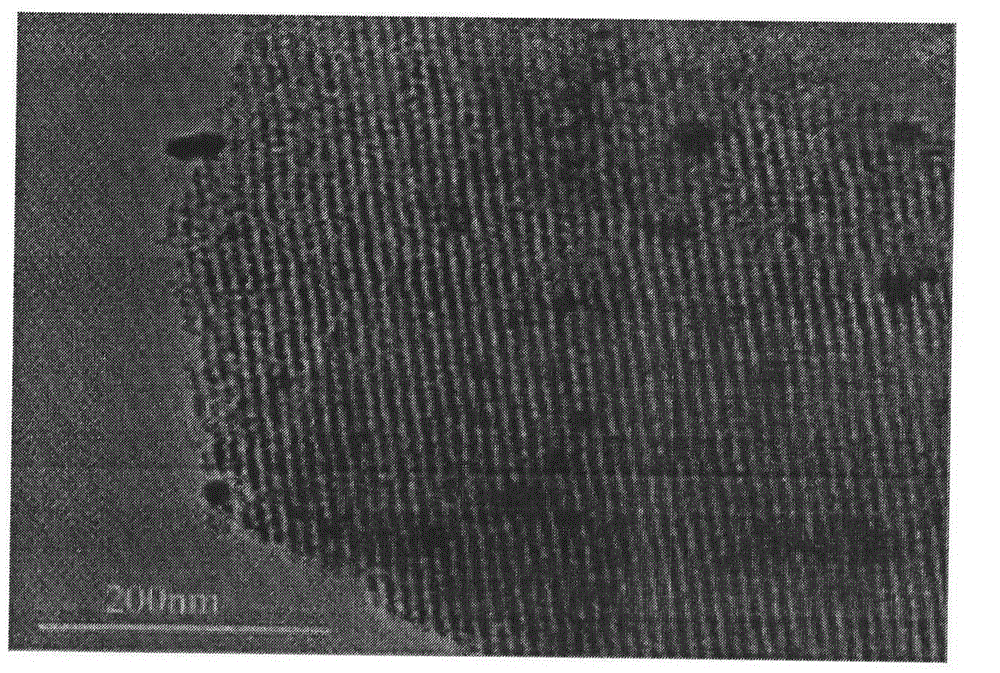

[0025] Add 3.2g of tri-block copolymer F127 into 32g of ethanol, stir magnetically at room temperature until completely dissolved. Dissolve 8g of 25% resole phenolic resin (phenol / formaldehyde) in ethanol and 4mL with 0.08g Cu(NO 3 ) 2 ·3H 2 O (copper nitrate trihydrate) ethanol solution was slowly added to the above solution and stirred for 2h. After stirring, the solution was allowed to stand at room temperature for 4 hours, the supernatant liquid was discarded, and the viscous sol in the lower layer was placed in a blast drying oven, and the temperature was set at 85°C for 24 hours. After drying, the sample was placed in a nitrogen-protected tube furnace, and the temperature was raised to 350°C at a heating rate of 1°C / min, kept at a constant temperature for 3 hours, and then raised to 900°C at a heating rate of 3°C / min, and kept at a constant temperature for 2 hours , and finally, the sample dropped to room temperature under the protection of nitrogen to obtain Cu-OMC c...

Embodiment 2

[0029] At 40°C, 0.06g Cu(CH3 COO) 2 ·H 2 O and 3.2g triblock copolymer F127 were added to 16g ethanol, stirred for 30min until completely dissolved. Slowly add 8g of 25% ethanol solution of resole phenolic resin (resorcinol / formaldehyde) into the above solution and stir for 2h, spread the solution evenly on a watch glass, evaporate the solvent for 4h at 30°C, and place the sample Place it in a blast drying oven, heat polymerization at 100°C for 24h. Then, the sample was placed in a nitrogen-protected tube furnace, and the temperature was raised to 350 °C at a heating rate of 1 °C / min, kept at a constant temperature for 3 h, then raised to 800 °C at a heating rate of 5 °C / min, and kept at a constant temperature for 2 h, and finally , the sample dropped to room temperature under the protection of nitrogen to obtain Cu-OMC catalyst.

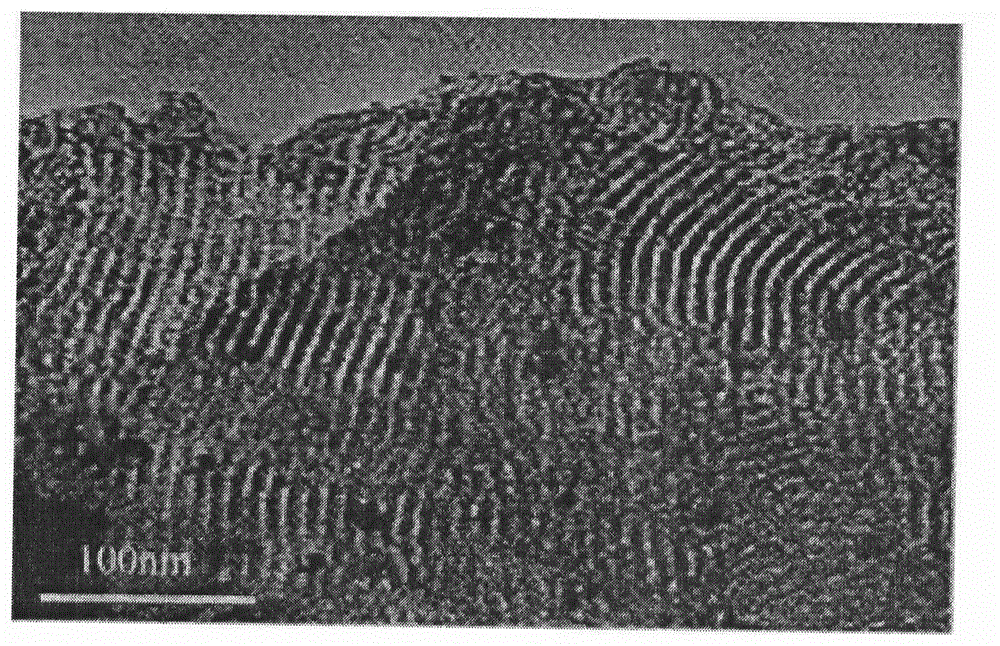

[0030] The transmission electron microscope test results of the catalyst are as follows: figure 2 . It can be seen that the Cu-OMC catalyst h...

Embodiment 3

[0033] Add 3.2g of tri-block copolymer F127 into 32g of ethanol, stir magnetically at room temperature until completely dissolved. 8 g of 25% ethanol solution of resole phenolic resin (phenol / formaldehyde) and 4 mL of ethanol solution dissolved with 0.08 g of copper oxalate were slowly added to the above solution in turn and stirred for 2 h. After stirring, the solution was allowed to stand at room temperature for 4 hours, the supernatant liquid was discarded, and the viscous sol in the lower layer was placed in a blast drying oven, and thermally polymerized at 85° C. for 24 hours. Then, the sample was placed in a nitrogen-protected tube furnace, raised to 300°C at a heating rate of 1°C / min, kept at a constant temperature for 3 hours, and then raised to 600-900°C at a constant temperature of 2-3°C / min. Keep it for 2-3h, and finally, the sample is lowered to room temperature under the protection of nitrogen to obtain Cu-OMC catalyst.

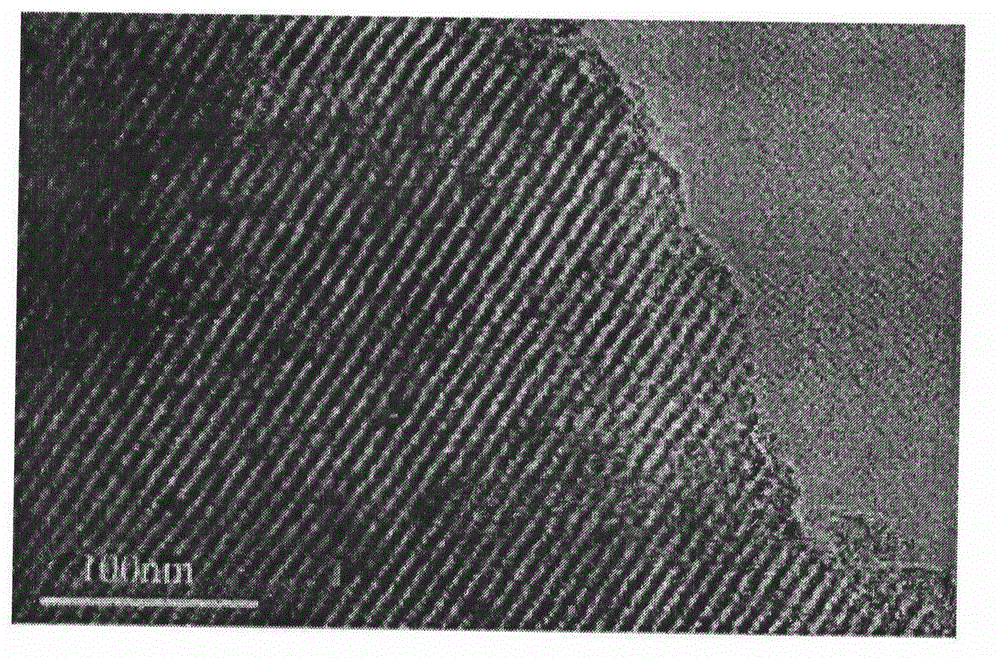

[0034] The transmission electron microsco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com