Method for modifying indium tin oxide electrochemiluminescence reaction electrodes

A technology of indium tin oxide and light-emitting electrodes, which is applied in the field of modification of indium tin oxide electrochemiluminescent reaction electrodes, can solve problems such as affecting the prospect and instability of indium tin oxide electrodes, and achieves good effect, low cost and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

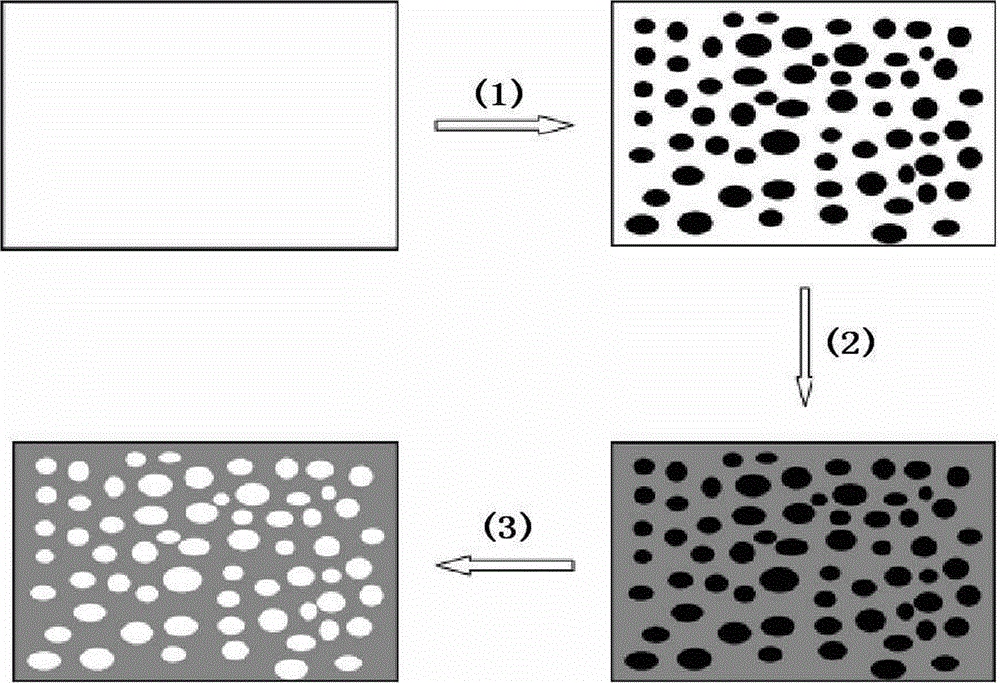

[0016] Indium tin oxide surface treatment: put the indium tin oxide electrode in 1% Triton X-100, absolute ethanol, and ultrapure water for ultrasonic cleaning for 20 min, and then use a volume ratio of deionized water: 30% hydrogen peroxide: 24 %Ammonia water=5:1:1 The mixed solution was boiled for 30 minutes to activate the surface of the indium tin oxide electrode. Ultrapure water was used to ultrasonically clean again for 20 min, and then the surface of the electrode was blown dry with dry nitrogen and treated at 110 °C for 30 min.

specific Embodiment 2

[0017] Ink dot spraying: Put indium tin oxide into the inkjet machine at room temperature, set the inkjet dot diameter (ink dot diameter range: 0.1 micron to 100 micron) and dot pitch (ink dot diameter range: 0.1 micron to 100 micron microns). Using UV ink (trimethylolpropane triacrylate 50%, dimethylphenylacetamide 12%, isopropylthioxanthone 1%, ethyl p-dimethylaminobenzoate 1%, toluene 25%, polymethyl methacrylate 10%, coloring agent 1%). The indium tin oxide electrodes covered by ink dots need to be dried in an oven immediately. The drying temperature is 80±5°C for 10-15 minutes. In this process, it is necessary to accurately control the drying conditions. If the temperature is too high or the time is too long, it will easily lead to difficulty in developing and difficult to remove the film. After drying, the electrodes are air-cooled or naturally cooled. The dried electrode needs to be gold-plated within 24 hours.

specific Embodiment 3

[0018] Cyanide-free gold plating process: Solution A: 0.5-2.5 grams of gold trichloride (AuCl 3 ) use distilled water to make a solution with a gold content of 20% to 25%, and then use 50% potassium hydroxide solution to neutralize the pH value to be 8 to 10;

[0019] Solution B: Dissolve 20-30 grams of ammonium sulfite in 50-60 mL of hot distilled water;

[0020] Preparation of gold plating solution: slowly add solution A to solution B and keep stirring, heat the mixed solution to 55-60°C until the solution becomes colorless and transparent, add 10-15 grams of potassium citrate, adjust the pH value to 8.5, and dilute to 100mL;

[0021] Temperature: 45~65℃;

[0022] Cathode current density: 0.1~0.8 A / dm 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com