Encapsulation structure and encapsulation method of optoelectronic device

A technology of optoelectronic devices and packaging methods, which is applied in the field of optoelectronics, can solve the problems of device performance degradation, stability degradation, black spots, etc., and achieve the effects of excellent device performance, extended device life, and good curing agent properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

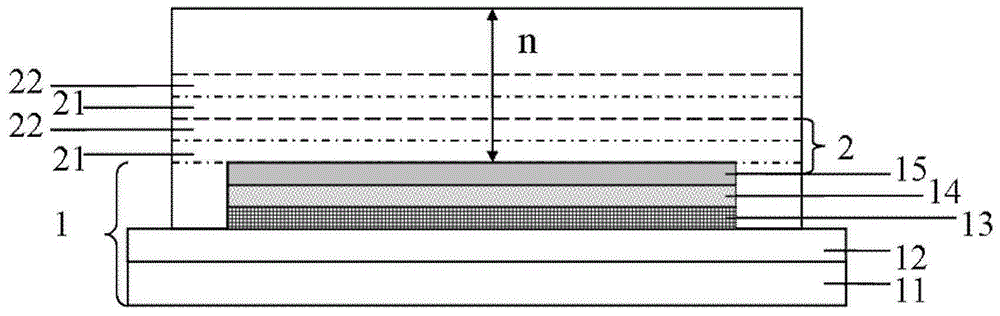

[0035] Such as figure 1 As shown, 1 is an organic electroluminescent device, the anode layer 12 is ITO, and the hole transport layer 13 is N,N'-bis(naphthylidene-1-yl)-N,N'-bis(phenyl) - benzidine (NPB), electron transport layer 14 is 1,3,5-(triN-phenyl-2-benzimidazole-2) benzene 41 (TPBi), cathode layer 15 is Mg:Ag alloy, inorganic package Material layer 21 is Al 2 o 3 , the UV-curable resin layer 22 includes 70% shellac, 15% reaction diluent and 15% triarylsulfur-type hexafluoroantimony salt, the number of cycles n is 20, and the device structure is:

[0036] Glass substrate / ITO / NPB(50nm) / TPBi(30nm) / Mg:Ag(200nm) / [Al 2 o 3 (200nm) / UV curable resin (100nm)] 20

[0037] The preparation method is as follows:

[0038] ①Use detergent, acetone solution, ethanol solution and deionized water to ultrasonically clean the substrate and dry it with nitrogen;

[0039] ②Transfer the clean substrate to the high vacuum evaporation chamber, and keep the pressure of the organic cavity ...

Embodiment 2

[0046] Such as figure 1 As shown, 1 is an organic electroluminescent device, the anode layer 12 is ITO, and the hole transport layer 13 is N,N'-bis(naphthylidene-1-yl)-N,N'-bis(phenyl) - benzidine (NPB), electron transport layer 14 is 1,3,5-(triN-phenyl-2-benzimidazole-2) benzene 41 (TPBi), cathode layer 15 is Mg:Ag alloy, inorganic package Material layer 21 is Al 2 o 3 , the UV-curable resin layer 22 includes 82% shellac, 10% reaction diluent and 8% triarylsulfur-type hexafluoroantimony salt, the number of cycles n is 16, and the device structure is:

[0047] Glass substrate / ITO / NPB(50nm) / TPBi(30nm) / Mg:Ag(200nm) / [Al 2 o 3 (200nm) / UV curable resin (100nm)] 16

[0048] The preparation method is similar to Example 1.

Embodiment 3

[0050] Such as figure 1 As shown, 1 is an organic electroluminescent device, the anode layer 12 is ITO, and the hole transport layer 13 is N,N'-bis(naphthylidene-1-yl)-N,N'-bis(phenyl) - benzidine (NPB), electron transport layer 14 is 1,3,5-(triN-phenyl-2-benzimidazole-2) benzene 41 (TPBi), cathode layer 15 is Mg:Ag alloy, inorganic package Material layer 21 is Al 2 o 3 , the UV-curable resin layer 22 includes 85% shellac, 10% reaction diluent and 5% triarylsulfur hexafluoroantimony salt, the number of cycles n is 12, and the device structure is:

[0051] Glass substrate / ITO / NPB(50nm) / TPBi(30nm) / Mg:Ag(200nm) / [Al 2 o 3 (200nm) / UV curable resin (100nm)] 12

[0052] The preparation method is similar to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com