High-temperature-resistant anti-aging electric power insulation material and production method thereof

An insulating material, anti-aging technology, applied in rubber insulators, organic insulators, plastic/resin/wax insulators and other directions, can solve the problem of aging resistance not meeting the expected requirements, insufficient mechanical strength and heat resistance, unfavorable promotion and use, etc. problems, to achieve the effect of improving fusion efficiency and fusion quality, high mechanical performance, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

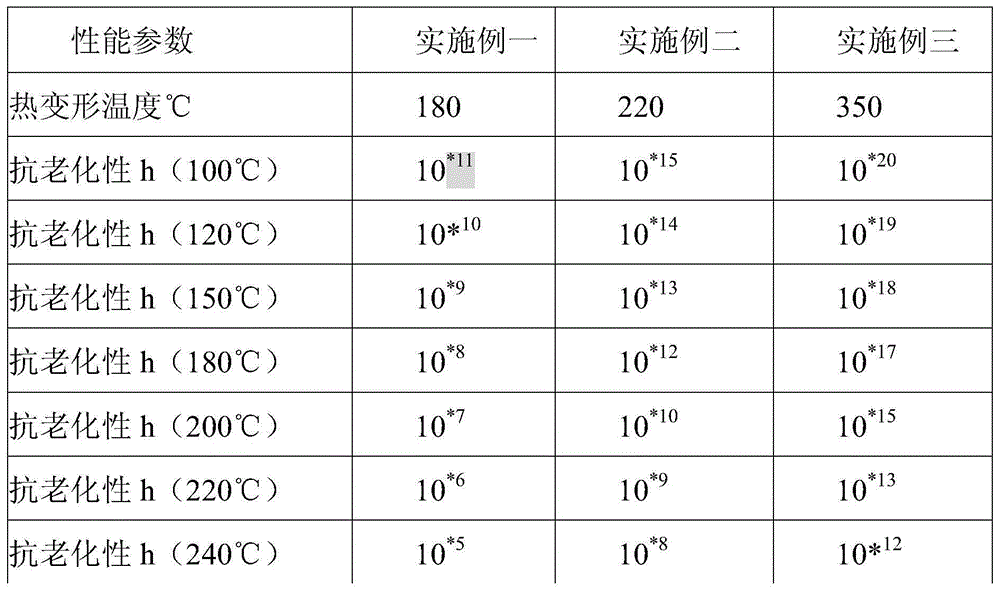

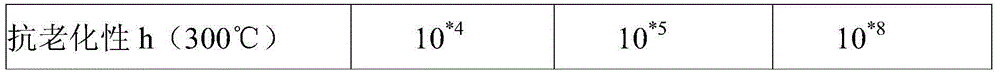

Embodiment 1

[0049] A high temperature and anti-aging electrical insulation material, including EPDM rubber, plasticizer, chloroplatinic acid, rubber softening oil, lubricant, ceramic powder, graphite powder, quartz sand, clay, magnesite, dolomite , lime powder, pine oil, silica gel, silicon nitride powder, glass fiber, polyvinyl chloride, polyvinyl alcohol, polycarbonate, sodium succinate, polydimethylsiloxane and hydroxyethyl cellulose, in parts by weight The ratio configuration is: EPDM rubber 30, plasticizer 12, chloroplatinic acid 2, rubber softening oil 10, lubricant 1, ceramic powder 20, graphite powder 15, quartz sand 8, clay 2, magnesite 4, Dolomite 42, lime powder 20, pine oil 5, silica gel 10, silicon nitride powder 12, glass fiber 25, polyvinyl chloride 50, polyvinyl alcohol 60, polycarbonate 40, sodium succinate 20, polydimethylsiloxane Oxane 32 and hydroxyethyl cellulose 15, the length of the glass fiber is preferably 3mm, the pore volume of the silica gel is 0.4ml / g, and the...

Embodiment 2

[0088] A high temperature and anti-aging electrical insulation material, the material formula is configured according to the weight ratio: EPDM rubber 50, plasticizer 20, chloroplatinic acid 5, rubber softening oil 15, lubricant 2, ceramic powder 36 , graphite powder 25, quartz sand 18, clay 20, magnesite 30, dolomite 50, lime powder 38, pine oil 20, silica gel 35, silicon nitride powder 20, glass fiber 30, polyvinyl chloride 55, polyvinyl alcohol 90. Polycarbonate 45, sodium succinate 30, polydimethylsiloxane 45 and hydroxyethyl cellulose 50, the length of the glass fiber is preferably 5mm, the pore volume of the silica gel is 0.5ml / g, The average pore size is 4nm, and the other aspects and manufacturing steps are the same as in Example 1.

Embodiment 3

[0090] A high temperature and anti-aging electrical insulation material, the material formula is configured according to the weight ratio: EPDM rubber 40, plasticizer 16, chloroplatinic acid 3.5, rubber softening oil 12.5, lubricant 1.5, ceramic powder 28 , graphite powder 20, quartz sand 13, clay 11, magnesite 17, dolomite 46, lime powder 29, pine oil 12.5, silica gel 22.5, silicon nitride powder 16, glass fiber 27.5, polyvinyl chloride 52.5, polyvinyl alcohol 75. Polycarbonate 42.5, sodium succinate 25, polydimethylsiloxane 38.5 and hydroxyethyl cellulose 27.5, the length of the glass fiber is preferably 4mm, the pore volume of the silica gel is 0.45ml / g, The average pore size is 3.5nm, and the other aspects and manufacturing steps are the same as those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com