Vanadium titano-magnetite tailing glass-ceramic and preparation method thereof

A technology of vanadium-titanium magnetite and glass-ceramics, which is applied in the field of glass-ceramics and its preparation, can solve problems such as economic losses, resource waste, and large reserves, and achieve reduced production costs, neat and tight crystal grains, and safety and environmental issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

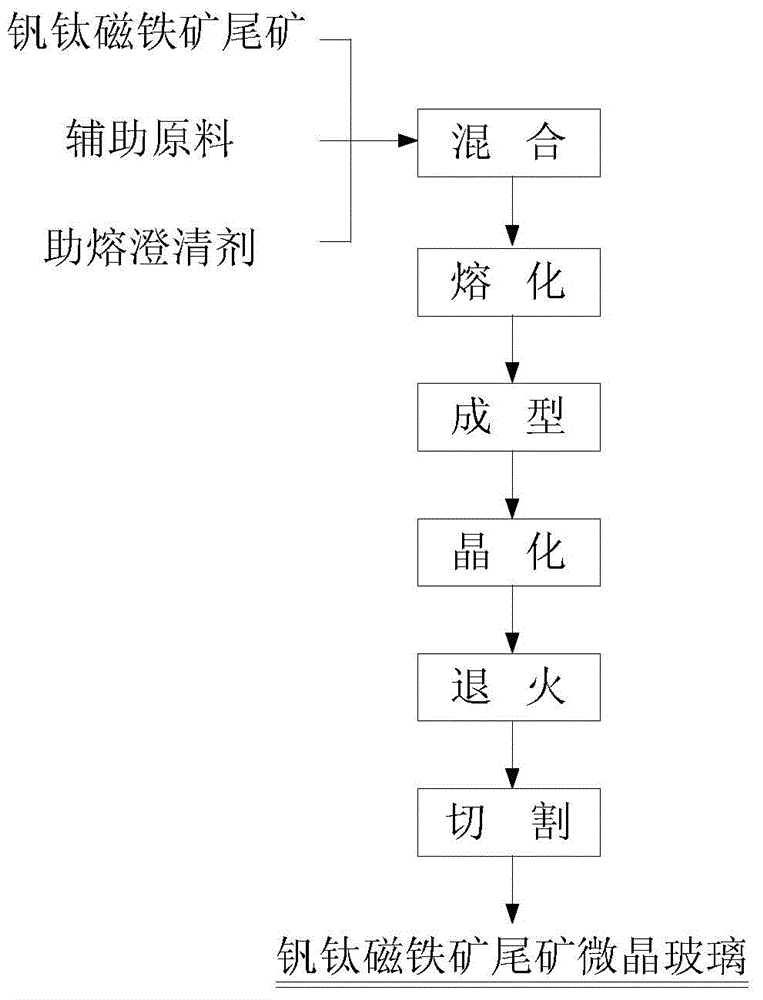

[0029] A vanadium-titanium magnetite tailings glass-ceramic and a preparation method thereof, comprising the following steps:

[0030] (1) Dry and pulverize the tailings of vanadium-titanium magnetite, accurately weigh 65.0kg of tailings, 16.6kg of quartz sand (SiO 2 ), 4.7kg alumina (Al 2 o 3 ), 6.4kg magnesium oxide (MgO), 6.2kg sodium carbonate (Na 2 CO 3 ), 4.4kg calcium carbonate (CaCO 3 ), 0.8kg chromium trioxide (Cr 2 o 3 ), 2.0kg fluorite (CaF 2 ), 2.2kg sodium nitrate (NaNO 3 ). The vanadium-titanium magnetite tailings, auxiliary raw materials and flux clarifying agent are put into the mixer and mixed evenly to form the basic batch of glass-ceramics.

[0031] (2) Put the basic batch material of glass-ceramic into a melting furnace for melting at a melting temperature of 1470° C. for 1.5 hours. After the melt is homogenized and clarified, a qualified molten glass is obtained.

[0032] (3) Pour the molten glass into the mold, and send it into the crystallizati...

Embodiment 2

[0036] A vanadium-titanium magnetite tailings glass-ceramic and a preparation method thereof, comprising the following steps:

[0037] (1) Dry and pulverize the vanadium-titanium magnetite tailings, accurately weigh 60.0kg tailings, 19.2kg quartz sand (SiO 2 ), 5.2kg alumina (Al 2 o 3 ), 6.7kg magnesium oxide (MgO), 6.5kg sodium carbonate (Na 2 CO 3 ), 5.7kg calcium carbonate (CaCO 3 ), 0.8kg chromium trioxide (Cr 2 o 3 ), 2.0kg fluorite (CaF 2 ), 2.2kg sodium nitrate (NaNO 3 ). The vanadium-titanium magnetite tailings, auxiliary raw materials and flux clarifying agent are put into the mixer and mixed evenly to form the basic batch of glass-ceramics.

[0038] (2) Put the basic batch material of glass-ceramic into a melting furnace for melting at a melting temperature of 1470° C. for 1.5 hours. After the melt is homogenized and clarified, a qualified molten glass is obtained.

[0039] (3) Pour the molten glass into the mold, and send it into the crystallization furnac...

Embodiment 3

[0043] A vanadium-titanium magnetite tailings glass-ceramic and a preparation method thereof, comprising the following steps:

[0044] (1) Dry and pulverize the vanadium-titanium magnetite tailings, accurately weigh 55.0kg tailings, 21.7kg quartz sand (SiO 2 ), 5.7kg alumina (Al 2 o 3 ), 6.9kg magnesium oxide (MgO), 6.7kg sodium carbonate (Na 2 CO 3 ), 0.3kg potassium carbonate (K 2 CO 3 ), 7.0kg calcium carbonate (CaCO 3 ), 0.8kg chromium trioxide (Cr 2 o 3 ), 2.0kg fluorite (CaF 2 ), 2.2kg sodium nitrate (NaNO 3 ). The vanadium-titanium magnetite tailings, auxiliary raw materials and flux clarifying agent are put into the mixer and mixed evenly to form the basic batch of glass-ceramics.

[0045] (2) Put the basic batch material of glass-ceramics into a high-temperature furnace for melting at a melting temperature of 1470° C. for 1.5 hours. After the melt is homogenized and clarified, a qualified glass liquid is obtained.

[0046] (3) Pour the molten glass into th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com