Natural preservative degradable food packaging paper and preparation method thereof

A food wrapping paper, natural antiseptic technology, applied in wrapping paper, wrapping paper, packaging, etc., can solve the problems of poor mechanical properties, limited moisture resistance, and insufficient application of edible packaging, etc., and achieve excellent antibacterial effect and long antibacterial time , unbreakable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

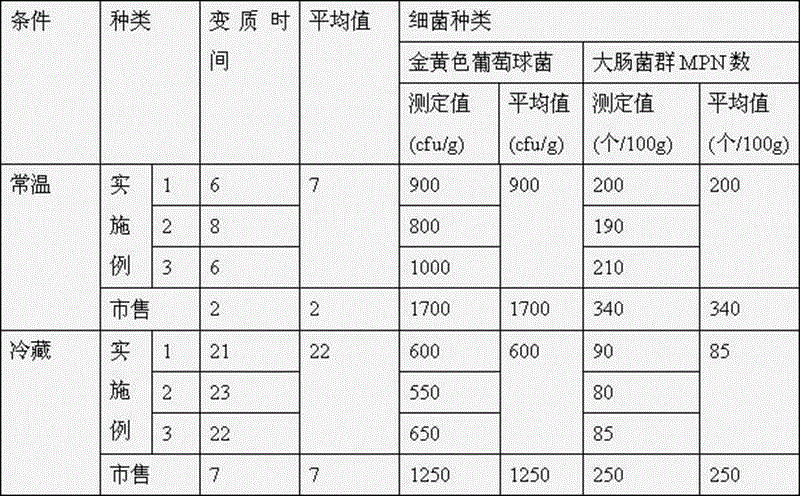

Examples

Embodiment 1

[0020] The preparation method of natural antiseptic and degradable food packaging paper comprises the following steps:

[0021] (1) Preparation of fiber layer: use rice straw or wheat straw as raw material, wash and soak in water containing baking soda for 3-5 days for degumming; add 600 parts of water and 4 parts of caustic soda for every 50 parts of straw, decoction of straw or wheat straw; dipped in dilute hydrochloric acid, washed with water, and dried; then crushed the treated straw or wheat straw for 25 minutes and passed through a 120-mesh sieve; mixed the crushed straw or wheat straw with talcum powder and agar gel 1. Add water to the starch glue and stir evenly, cool, store at room temperature and 0.15Mpa for 1.5h to obtain a film solution; use a coating rod to coat the film solution on a glass plate, and control the thickness of the wet film to 1-2mm; dry to obtain the fiber layer; the weight ratio of rice straw or wheat straw, agar glue, starch glue, talcum powder, ...

Embodiment 2

[0026] The preparation method of natural antiseptic and degradable food packaging paper comprises the following steps:

[0027] (1) Preparation of fiber layer: use rice straw or wheat straw as raw material, wash and soak in water containing baking soda for 5 days for degumming; add 500 parts of water and 3 parts of caustic soda for every 50 parts of straw, and degummed or wheat straw decocting; dipping in dilute hydrochloric acid, washing with water, and drying; then crushing the treated straw or wheat straw for 20 minutes, passing through a 100-mesh sieve; mixing the crushed straw or wheat straw with talcum powder, agar gel, starch Add water to the glue and stir evenly, cool, store at room temperature and 0.20Mpa for 1 hour to obtain a film solution; use a coating rod to coat the film solution on a glass plate, and control the wet film thickness to 1-2mm; dry to obtain a fiber layer; straw Or the weight ratio of wheat straw, agar glue, starch glue, talcum powder, and water is...

Embodiment 3

[0032] The preparation method of natural antiseptic and degradable food packaging paper comprises the following steps:

[0033] (1) Preparation of fiber layer: use rice straw or wheat straw as raw material, wash and soak in water containing baking soda for 3 days for degumming; add 700 parts of water and 5 parts of caustic soda for every 50 parts of straw, and degummed or wheat straw decocting; dipping in dilute hydrochloric acid, washing with water, and drying; then crushing the treated straw or wheat straw for 30 minutes, passing through a 150-mesh sieve; mixing the crushed straw or wheat straw with talcum powder, agar gel, starch Add water to the glue and stir evenly, cool, store at room temperature and 0.10Mpa for 2 hours to obtain a film solution; use a coating rod to coat the film solution on a glass plate, and control the wet film thickness to 1-2mm; dry to obtain a fiber layer; straw Or the weight ratio of wheat straw, agar glue, starch glue, talcum powder, and water i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com