A method for simultaneously preparing fumonisin b1, b2 and b3 standard substances

A technology of fumonisins and standard products, applied in the preparation of test samples, etc., can solve the problems of small amount of samples processed at one time, expensive scientific research, low recovery rate, etc., and achieve low preparation cost, strong repeatability, The effect of high purity standard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1 Preparation of Fumonisins B1, B2, B3 Standards

[0039] 1. Sample extraction

[0040] The dried fumonisin-contaminated rice samples (random commercially available rice, screened out fumonisin-contaminated samples) were pulverized in a solid grinder and filtered through a 1 mm pore size mesh sieve. Take 200±0.01g of the sample powder and place it in a 2000mL jar, add 1000mL of acetonitrile-water (50:50, v / v) solution, place on a shaker at 150rpm and shake overnight, then filter with whatma5 filter paper. The filter cake was resuspended with 1000 mL of acetonitrile-water (50:50, v / v), shaken at 150 rpm for 2 h, and filtered. The two filtrates were combined and concentrated in a rotary evaporator at 40° C. until the content of acetonitrile in the extract was about 10% (v / v).

[0041] 2. Solid phase extraction column purification

[0042] Take 20mL of the extract and place it in a 50mL centrifuge tube, add 10mL of n-hexane, centrifuge at 3000r / min for 10min, di...

Embodiment 1

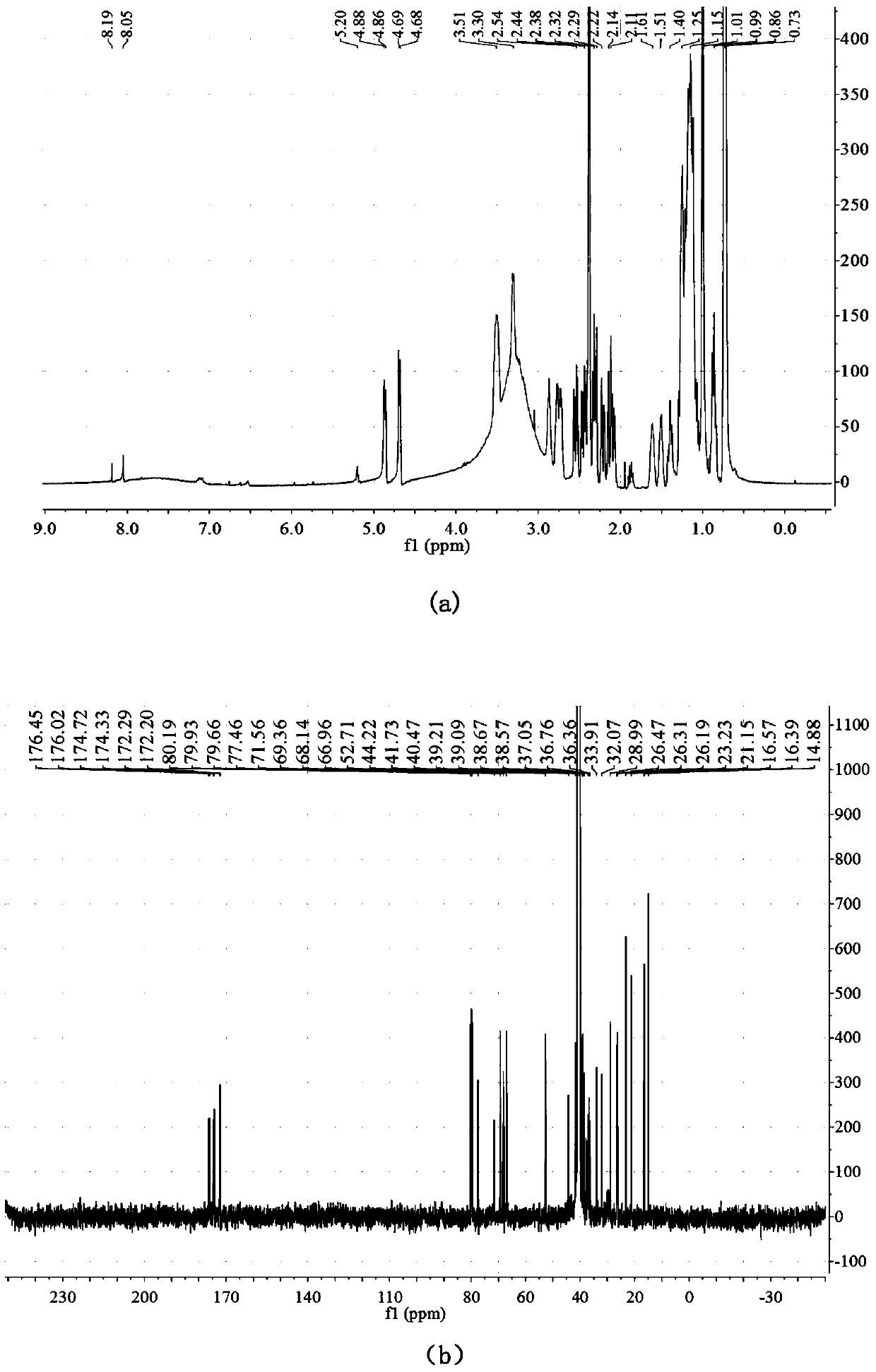

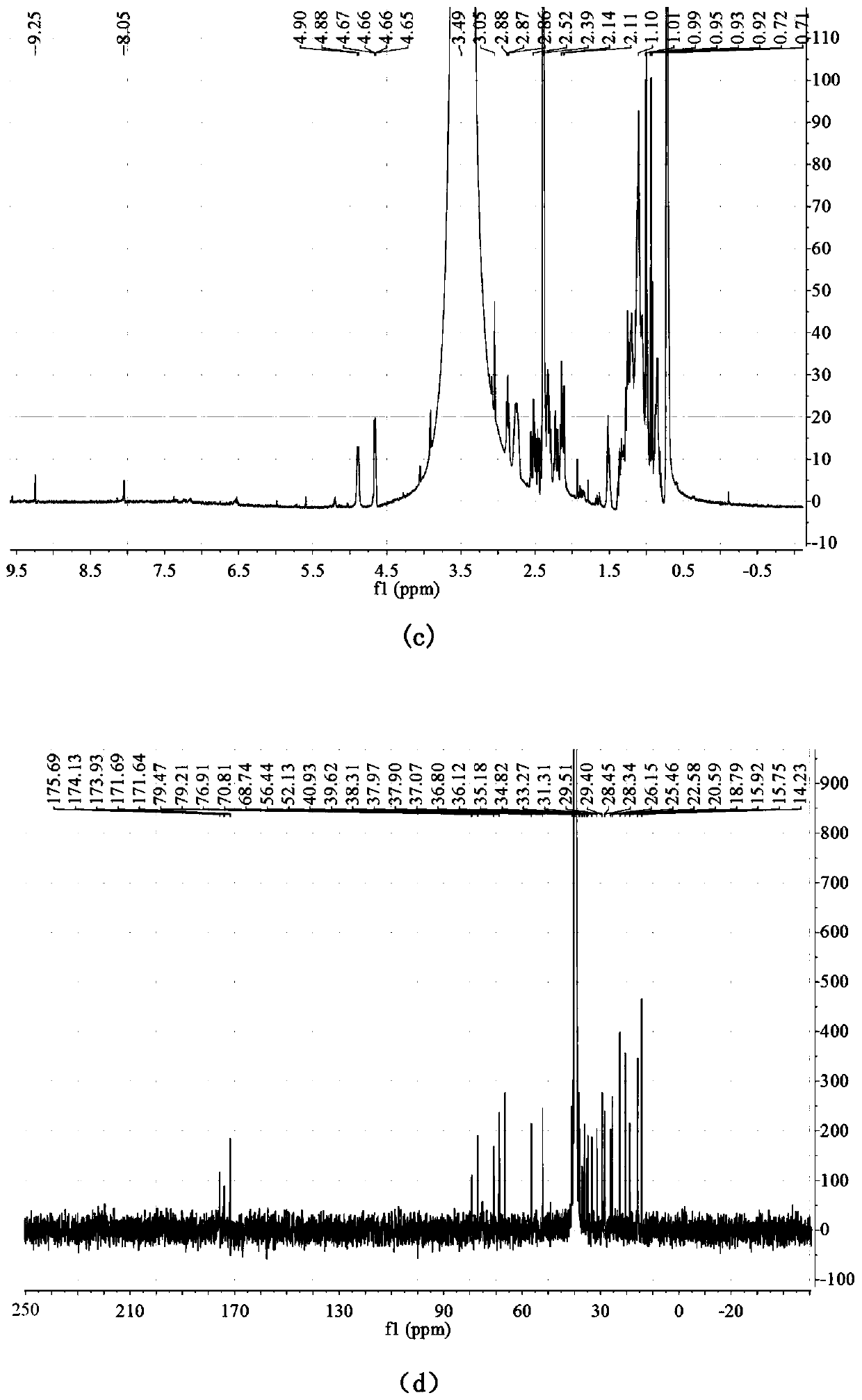

[0059] Carry out qualitative analysis and purity measurement to embodiment one preparation three kinds of standard products

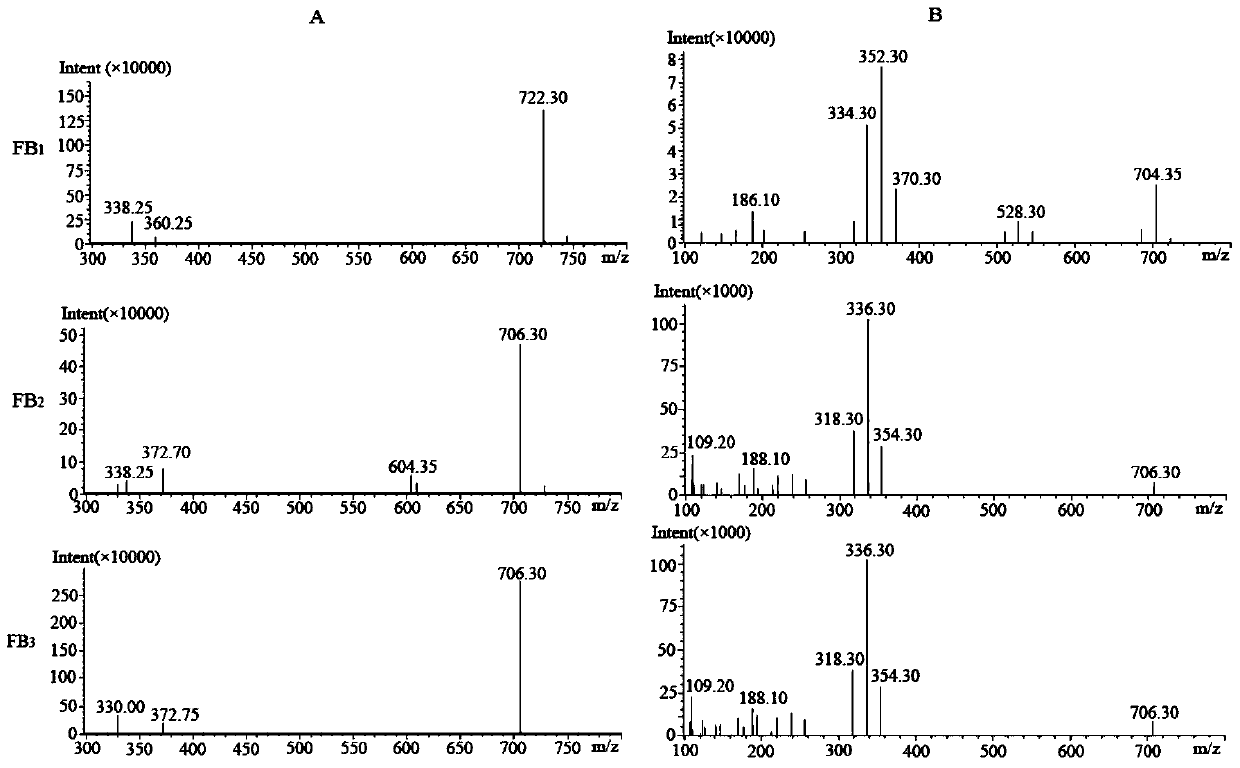

[0060] 1 Qualitative analysis by liquid chromatography mass spectrometry (LC-MS / MS)

[0061] LC-MS / MS conditions: Thermo C18 chromatographic column (2.1mm×100mm, 5μm); mobile phase A is methanol, mobile phase B is aqueous solution containing 0.1% formic acid (v / v); gradient elution: 0~1mim, 50%B~50%B; 1-7min, 50%B~100%B; 7~8min, 100%B~100%B; 8~8.2min, 100%B~50%B; 8.2~9.0min, 50% B to 50% B; flow rate 300 μL / min; injection volume 5 μL; column temperature 30°C. Fragmentation voltage is 1.5V; spray voltage is 3.5kV; atomization air pressure adopts electrospray ESI ion source (both positive and negative ions are used), scanning force is 3500Pa; capillary temperature is 350°C; sheath air pressure is 45Pa; auxiliary air pressure is 15Pa. The scanning range is m / z300~800; the collision voltage of product ion fragments is 30eV.

[0062] Get FB 1 , FB 2 , F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com