Method for industrially preparing medium-chain triglyceride

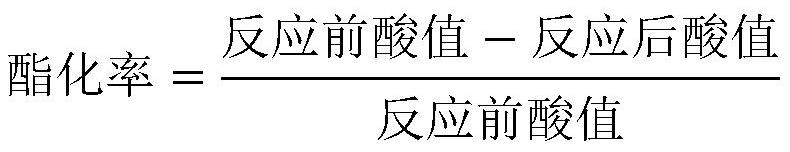

A medium-carbon chain triglyceride and a technology for carbon-chain triglycerides are applied in the field of industrialized preparation of medium-carbon chain triglycerides, can solve the problems of many side reactions, dehydration, and high investment costs, and reduce production costs, yield and The effect of high esterification rate and time shortening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

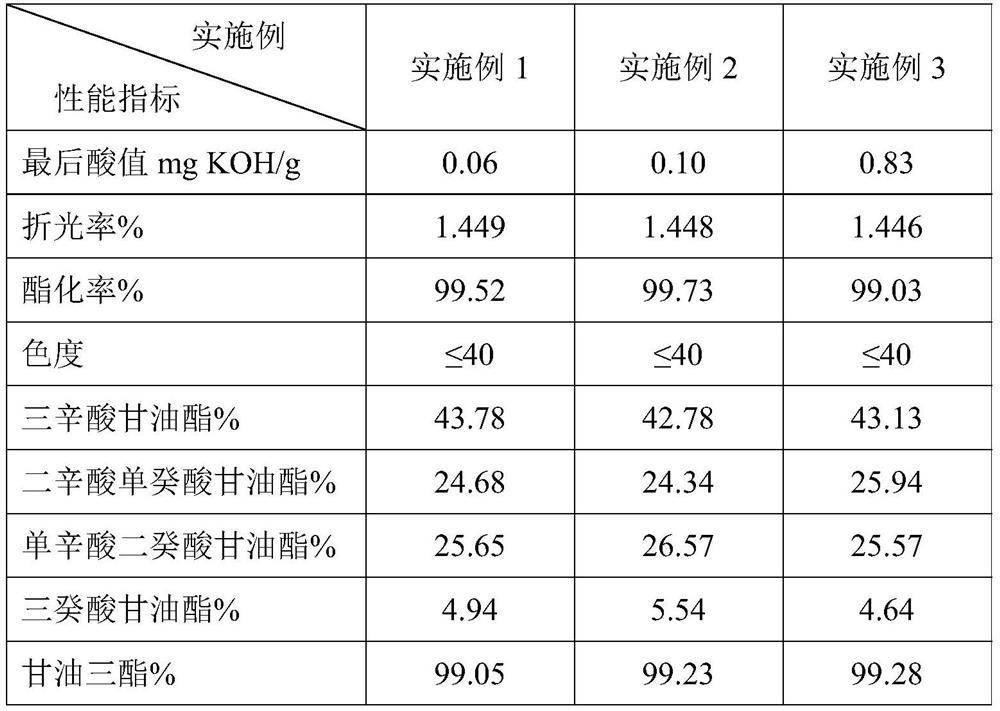

Embodiment 1

[0046] The present embodiment has prepared a kind of caprylic acid-capric triglyceride, and specific process is:

[0047](1) Measure 3kg of industrial grade glycerin, 12kg of caprylic acid and 6kg of capric acid respectively through a meter, and transport each raw material into the esterification reactor through a vacuum pump; simultaneously open the heating device, the vacuum device and the stirring device of the esterification reactor, Control the pressure of the reactor to -0.1MPa, and the stirring speed to 100r / min; when the temperature of the material system in the reactor rises to 70°C-90°C, keep stirring for 20 minutes in this state to remove the air carried in the raw material Moisture and other volatile gases are added with a catalyst (the mass of p-toluenesulfonic acid accounts for 45%, and the mass of hypophosphorous acid accounts for 55%). The mass of the catalyst is 0.7% of the total mass of raw materials. Carry out three-stage programmatic temperature rise and de...

Embodiment 2

[0051] The present embodiment has prepared a kind of caprylic acid-capric triglyceride, and specific process is:

[0052] (1) Measure 3kg of industrial grade glycerin, 9kg of caprylic acid and 6kg of capric acid respectively through a meter, and transport each raw material into the esterification reactor through a vacuum pump; simultaneously open the heating device, vacuum device and stirring device of the esterification reactor, Control the pressure of the reactor to -0.1MPa, and the stirring speed to 100r / min; when the temperature of the material system in the reactor rises to 70°C to 80°C, keep stirring for 20 minutes in this state to remove the air carried in the raw materials Moisture and other volatile gases are added with a catalyst (the mass of p-toluenesulfonic acid accounts for 40%, and the mass of hypophosphorous acid accounts for 60%). The mass of the catalyst is 1.0% of the total mass of raw materials. Carry out three-stage programmed temperature rise and depressu...

Embodiment 3

[0056] The present embodiment has prepared a kind of caprylic acid-capric triglyceride, and specific process is:

[0057] (1) Measure 4kg of industrial grade glycerin, 11kg of caprylic acid and 9kg of capric acid respectively through a meter, and transport each raw material into the esterification reactor through a vacuum pump; simultaneously open the heating device, the vacuum device and the stirring device of the esterification reactor, Control the pressure of the reactor to -0.1MPa, and the stirring speed to 90r / min; when the temperature of the material system in the reactor rises to 80°C to 90°C, keep stirring for 20 minutes in this state to remove the air carried in the raw materials Moisture and other volatile gases are added with a catalyst (the mass of p-toluenesulfonic acid accounts for 50%, and the mass of hypophosphorous acid accounts for 50%). The mass of the catalyst is 0.4% of the total mass of raw materials. Carry out three-stage programmed temperature rise and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com