Method for determining element content in ferroalloy and pretreatment method for its sample

A technology of sample pretreatment and element content, which is applied in the preparation of test samples, measuring devices, instruments, etc., can solve the problems of complex melting operation, high cost of chemical reagents, protracted process, etc., so as to achieve easy mastery and operation , less consumption of pharmaceutical reagents, less reaction conditions and less demanding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

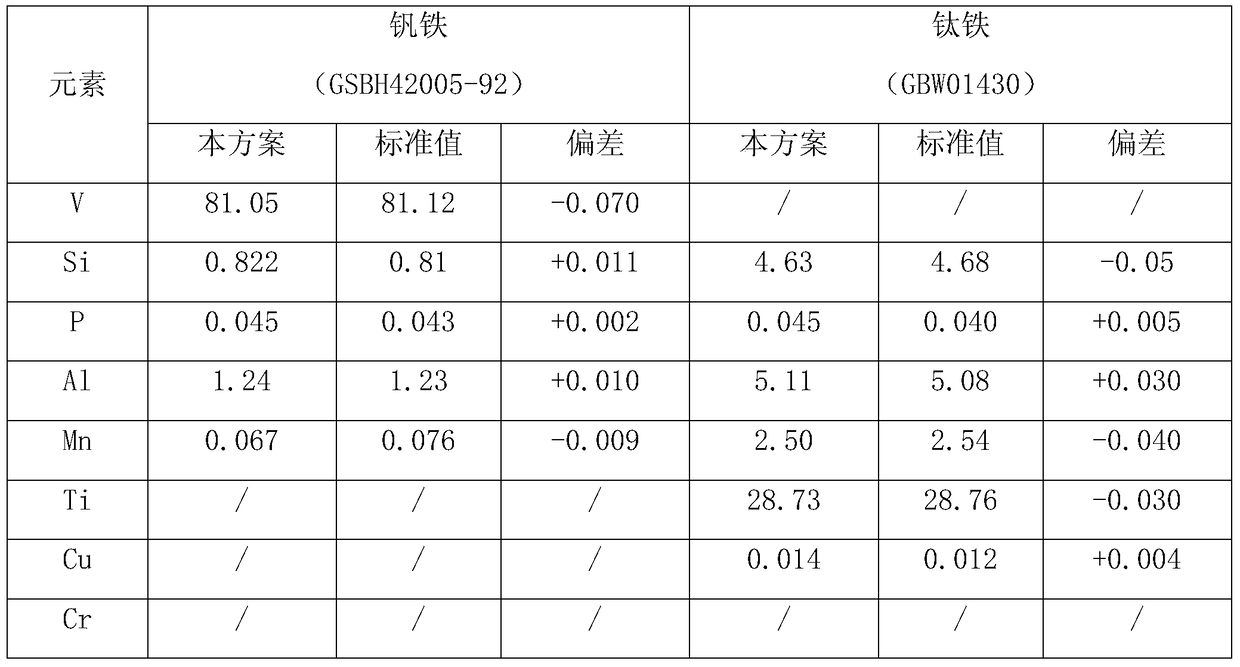

[0041] Embodiment 1 adopts the inventive method to measure the content of each element in ferrovanadium ferroalloy

[0042] Alkaline mixed flux is formulated according to anhydrous sodium carbonate: anhydrous boric acid=1:1 composition ratio, namely weighing 500g anhydrous sodium carbonate and 500g boric acid are mixed together and crushed, ground and mixed, and the amount of flux is sample quality 10 times. Weigh 5.0g of alkaline mixed flux and 0.5g of the ferrovanadium sample to be tested and mix them evenly in filter paper, wrap and fold the filter paper and place them in a graphite-bottomed crucible, and melt and react in a muffle furnace at 900°C for 25 minutes.

[0043] The melted and digested ferrovanadium sample was cooled to remove the attached graphite powder, crushed, ground, mixed and sieved with a 0.125mm sieve with a tungsten carbide mortar, and the molten sample was reprocessed to prepare a powder state. The basic mixed flux prepared by the above-mentioned anhy...

Embodiment 2

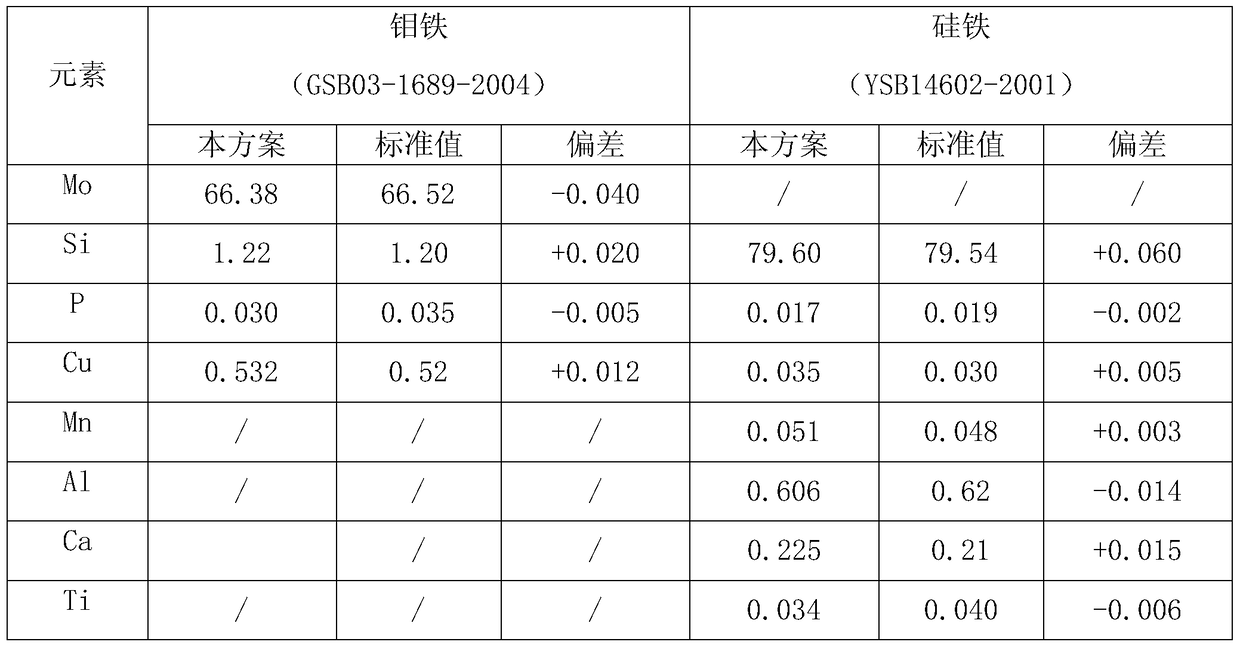

[0045] Embodiment 2 adopts the inventive method to measure the content of each element in ferro-niobium ferroalloy

[0046] Except for the following differences, all the others adopt the same method as in Example 1 to carry out the preparation of powder tablets and the determination of elemental components in Example 2: the detection object of Example 2 is a niobium-iron alloy sample; Anhydrous sodium carbonate: anhydrous boric acid=2:1 composition ratio preparation, promptly weigh 1000g anhydrous sodium carbonate and 500g boric acid and mix together and crush, grind and mix, and flux consumption is 20 times of sample quality; Take 20.0g of mixed flux and 1.0g of ferroniobium sample to be tested, and melt at 1000°C for 20min. The powder compression condition is 10s under the pressure of 18 tons. The results of the content of each element in the alloy are shown in Table 4.

Embodiment 3

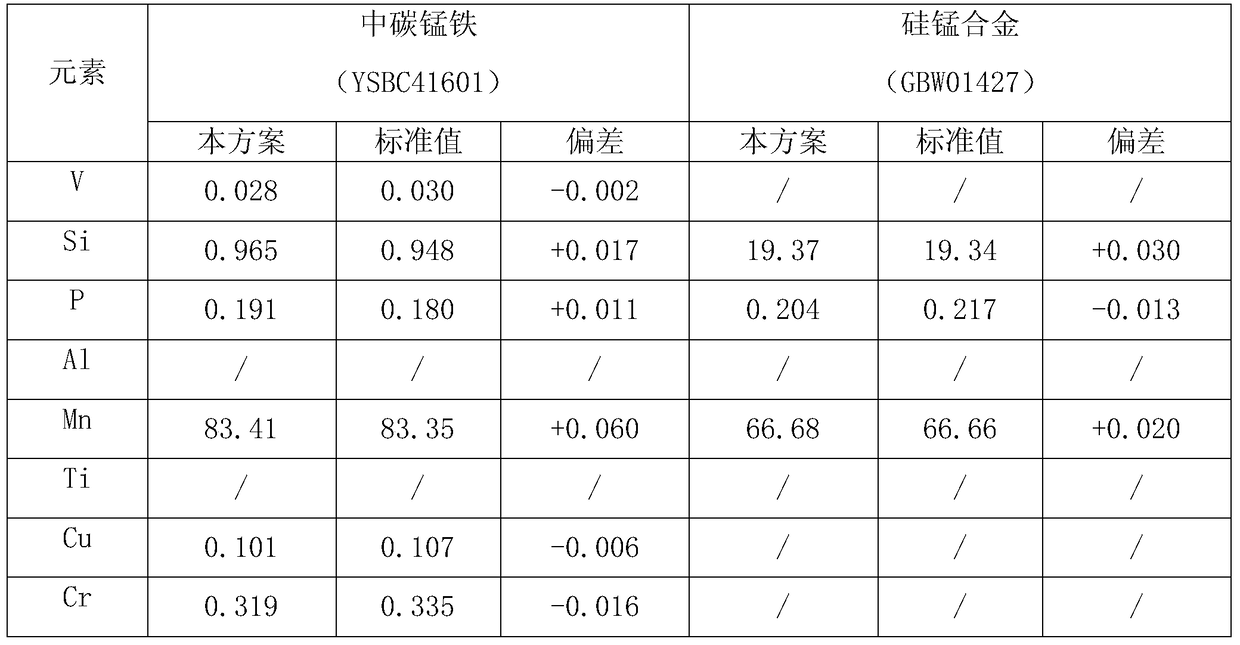

[0047] Embodiment 3 adopts the inventive method to measure the content of each element in ferrosilicon class ferroalloy

[0048] Except for the following differences, all the others adopt the same method as in Example 1 to carry out the powder tablet preparation and element composition determination of Example 3: the detection object of Example 3 is a ferrosilicon-like ferroalloy sample; Anhydrous sodium carbonate: anhydrous boric acid = 1:1 composition ratio, the amount of flux is 15 times the mass of the sample; weigh 15.0g of the mixed flux and 1.0g of the ferroniobium sample to be tested, and melt at 950°C for 22min. The powder compression condition is 8s under the pressure of 16 tons. The results of the content of each element in the alloy are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com