Quantitative detection device and method for interface reaction degree of aluminum-carbon composite material

A carbon composite material and interfacial reaction technology, applied in the direction of measuring devices, material separation, and analysis of materials, can solve problems such as misjudgment, insufficient scale accuracy, and inability to directly observe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

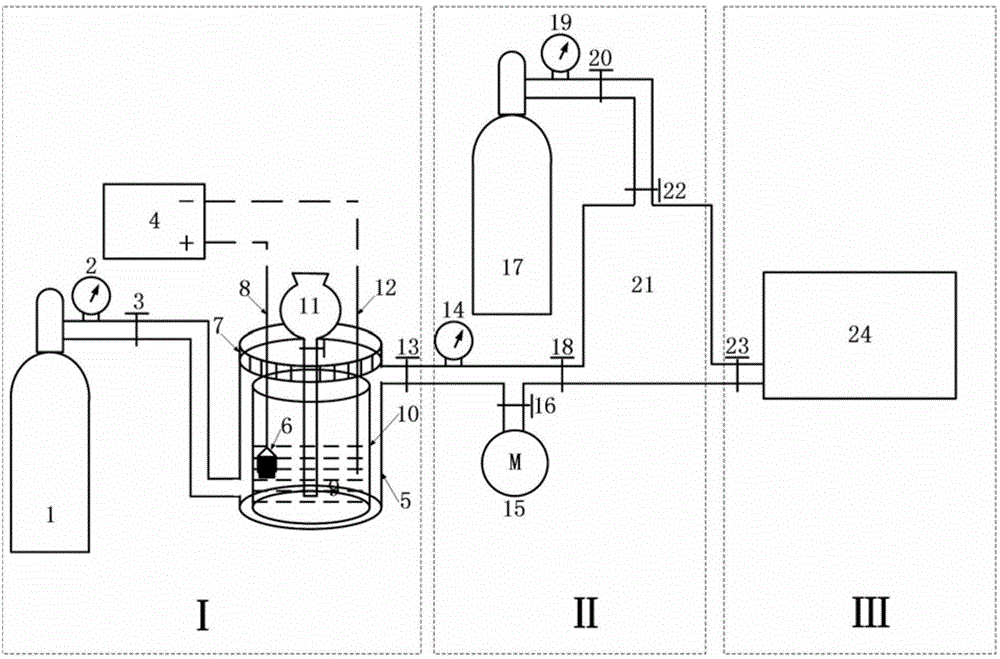

[0068] The CNT / Al composites with a mass fraction of 2% were prepared by powder metallurgy process and sintered at 570°C, 600°C, and 630°C for 2h, respectively.

[0069] (1) Cut thin slice samples of a certain size respectively, weigh their quality, and be clamped on the platinum electrode holder 8; open the vacuum mechanical pump 15 (open the third valve 16) before the reaction begins, exhaust the air in the device, wait After the vacuum reaches the requirement, close the vacuum mechanical pump 15 (close the third valve 16); open the auxiliary gas cylinder 1 (open the first valve 3), and feed nitrogen; repeat the operation twice to exhaust the air in the device.

[0070] (2) Open the separatory funnel 11 valves, inject 200mL sodium hydroxide solution into the glass beaker 10; turn on the DC power supply 4, the DC power supply 4 is set to a constant current mode, and the current is set to 2A to start the electrolysis reaction, the gas collection chamber 21 Collect the reaction...

Embodiment 2

[0085] Graphene / Al composites with a mass fraction of 2% were prepared by powder metallurgy process and sintered at 570°C, 600°C, and 630°C for 2h, respectively.

[0086] (1) Cut thin slice samples of a certain size respectively, weigh their quality, and the rod is clamped on the platinum electrode holder 8; open the vacuum mechanical pump 15 before the reaction starts, exhaust the air in the device, and close the vacuum after the vacuum degree reaches the requirement Mechanical pump 15; open the auxiliary gas cylinder 1, feed nitrogen; repeat the operation twice, and exhaust the air in the device.

[0087] (2) Open the valve of the separating funnel 11, inject 200mL of sodium hydroxide solution into the glass beaker 10; turn on the DC power supply 4, set the DC power supply 4 to a constant current mode, and set the current to 2A, start the electrolysis reaction, and collect the reaction to generate gas .

[0088] (3) After the thin slice sample is completely dissolved, turn ...

Embodiment 3

[0101] In order to verify the detection limit of the device of the present invention, a powder metallurgy process was used to prepare a limit sample of CNT / Al and graphene / Al with a mass fraction of 0.5%, and sintered at 640 ° C for 10 h to make carbon nanotubes and graphene react completely into Al 4 C 3 . Cut 0.5g sample and test with device of the present invention, the statistical result after 5 repeated tests is as shown in table 7:

[0102] Table 7 Test results of CNT / Al and graphene / Al extreme samples

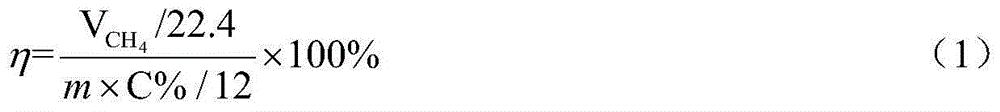

[0103] Material

[0104] The present invention utilizes the interface reaction product Al 4 C 3 The principle of the property of being easy to hydrolyze first accelerates the dissolution of the sample to be tested by means of an electrochemical reaction, and then analyzes the Al by gas chromatography. 4 C 3 CH produced by hydrolysis 4 The gas concentration is accurately tested, and the degree of interface reaction is finally calculated; the invention is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com