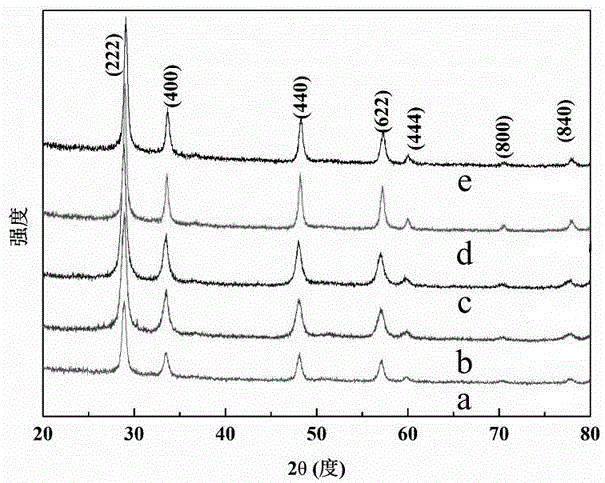

Preparation method and use of yttrium-doped bismuth stannate nanocrystallines

A technology of bismuth stannate and nanocrystals is applied in the field of inorganic nano-semiconductor material synthesis, which can solve the problem of high cost and achieve the effects of low cost, convenient mass production and reduced energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

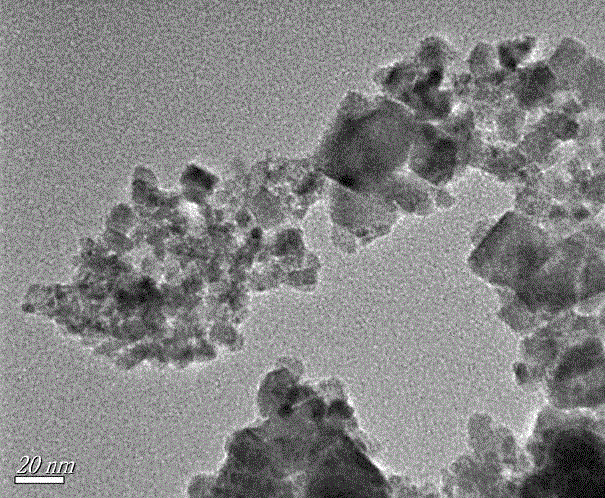

Embodiment 1

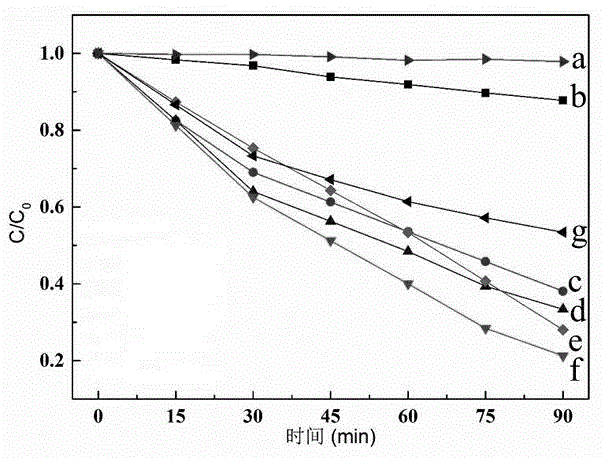

[0032] Take by weighing 1.94028g bismuth nitrate (Bi(NO 3 ) 3 ?5H 2 O) was dissolved in 10mL 1M dilute nitric acid to obtain mixed solution A; 1.13896g sodium stannate (Na 2 SnO 6 ?4H 2 O) Dissolve in 10ml double-distilled water to obtain an aqueous solution of sodium stannate, transfer the aqueous solution of sodium stannate into mixed solution A to obtain mixed solution B, adjust to pH=12 with NaOH solution. Transfer the mixed solution B with pH=12 into a 50mL polytetrafluoroethylene-lined reactor, and keep the temperature at 180°C for 24h. The product was alternately centrifuged and washed with water and ethanol, and dried in vacuum at 60° C. for 12 hours to obtain bismuth stannate nanocrystals.

[0033] Get 0.05g of the bismuth stannate nanocrystals prepared in this example and add them into a 100mL photocatalytic reactor containing 10mg / L tetracycline aqueous solution, and stir in the dark at room temperature for 30 minutes to reach adsorption-desorption equilibrium;...

Embodiment 2

[0035] Take by weighing 1.92087g bismuth nitrate (Bi(NO 3 ) 3 ?5H 2 O) and 0.00766g yttrium nitrate (Y(NO 3 ) 3 ·6H 2 O) was dissolved in 10mL 1M dilute nitric acid to obtain mixed solution A; 1.12757g sodium stannate (Na 2 SnO 6 ?4H 2O) Dissolve in 10ml double distilled water to obtain an aqueous solution of sodium stannate, transfer the aqueous solution of sodium stannate into the above mixed solution A to obtain a mixed solution B, and ultrasonically stir the mixed solution B until it becomes a milky white mixed solution , adjusted to pH=12 with NaOH solution. Transfer the mixed solution with pH=12 into a 50mL polytetrafluoroethylene-lined reactor, and keep the temperature at 180°C for 24h. The product was alternately centrifuged and washed with water and ethanol, and dried in vacuum at 60° C. for 12 hours to obtain yttrium-doped bismuth stannate nanocrystals.

[0036] The yttrium-doped bismuth stannate nanocrystals prepared in this example were used for photocatal...

Embodiment 3

[0038] Take by weighing 1.88207g bismuth nitrate (Bi(NO 3 ) 3 ?5H 2 O) and 0.02298g yttrium nitrate (Y(NO 3 ) 3 ·6H 2 O) was dissolved in 10mL 1M dilute nitric acid to obtain mixed solution A; 1.10479g sodium stannate (Na 2 SnO 6 ?4H 2 O) be dissolved in 10ml double-distilled water to obtain an aqueous solution of sodium stannate, transfer the aqueous solution of sodium stannate to mixed solution A to obtain mixed solution B, and ultrasonically stir mixed solution B until it becomes a milky white mixed solution, Adjust to pH=12 with NaOH solution. Transfer the mixed solution with pH=12 into a 50mL polytetrafluoroethylene-lined reactor, and keep the temperature at 180°C for 24h. The product was alternately centrifuged and washed with water and ethanol, and dried in vacuum at 60° C. for 12 hours to obtain yttrium-doped bismuth stannate nanocrystals.

[0039] The yttrium-doped bismuth stannate nanocrystals prepared in this example were used for photocatalytic degradation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com