Method for rapidly growing large-size high-purity semi-insulating silicon carbide single crystal

A silicon carbide single crystal, semi-insulating technology, applied in chemical instruments and methods, single crystal growth, crystal growth and other directions, can solve the problems of reducing Al, difficult to reduce, low production efficiency, etc., to improve productivity and reduce nitrogen content , the effect of increasing the resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

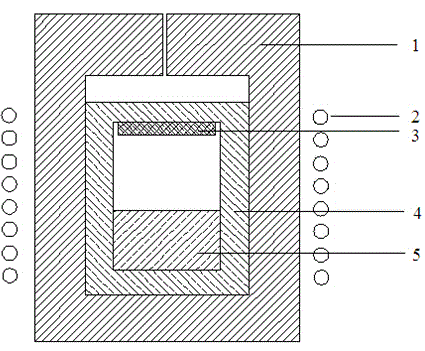

Image

Examples

Embodiment 1

[0016] A 3-inch silicon carbide single crystal is grown in an induction heating PVT SiC single crystal furnace, and the specific steps are as follows:

[0017] (1) Place the SiC source powder on the lower part of the graphite crucible, place the SiC seed crystal on the upper part of the graphite crucible, the diameter of the SiC seed crystal is 3 inches, the growth surface is the carbon surface, and the growth direction is on-axis;

[0018] (2) Place the assembled graphite crucible in a high-frequency induction heating furnace;

[0019] (3) Use a molecular pump to evacuate the high-frequency induction heating furnace until the vacuum degree in the growth chamber reaches 5×10 -5 Below mbar;

[0020] (4) Introduce H into the growth chamber 2 and CH 4 Mixed gas, the ratio of the two is 1 : 1. The gas flow rate is 10mL / min, and the feeding time is 30min;

[0021] (5) After an interval of 30 minutes, inject the same amount of replacement gas as in step (4);

[0022] (6) The t...

Embodiment 2

[0025] The specific implementation steps of this example are different from those of Example 1: Repeat step (5) in Example 1 four times, that is, repeat the filling of replacement gas five times in total. The rest of the steps in this example are the same as in Example 1. I won’t go into details here. A 6H high-purity semi-insulating silicon carbide single crystal with a length greater than 3 cm and a diameter greater than 3 inches was obtained. The growth rate was greater than 0.6 mm / h. After cutting, grinding, and polishing, the resistivity was greater than 10 8 Ω·cm, the nitrogen content in the wafer was tested with a secondary ion mass spectrometer IMS-4F, and the nitrogen content was lower than 9×10 16 atom / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap