Mode beam-splitting converter based on grating-assisted coupler

A converter and coupler technology, used in light guides, optics, instruments, etc., can solve the problems of careful control and small process tolerance, and achieve the effects of convenient low-cost manufacturing, high conversion efficiency, and no beat growth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

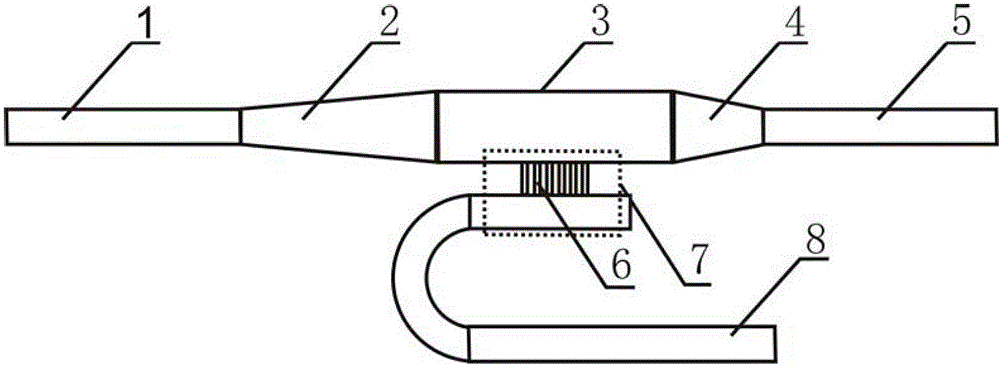

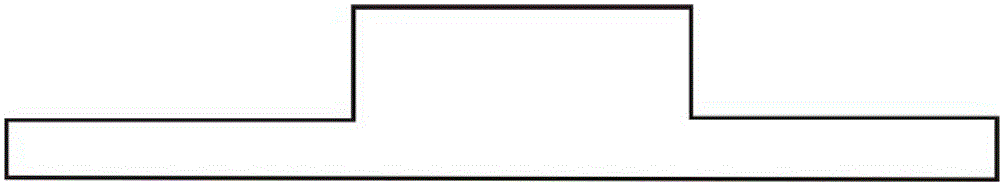

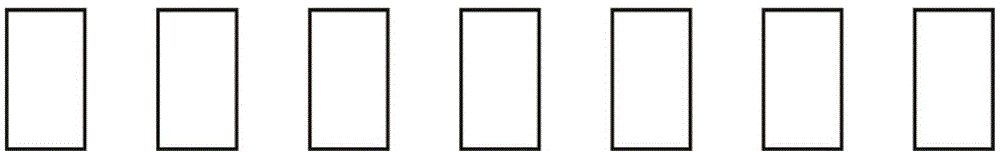

[0032] Such as figure 1 with Figure 4 As shown, the silicon-on-insulator (SOI) material with a thickness of 220nm on the top layer of silicon and a buried silicon dioxide layer of 2μm is used. After cleaning the wafer surface, perform deep ultraviolet lithography or electron beam direct writing lithography to obtain silicon etching. Mask, through silicon dry etching twice, a single-mode silicon ridge waveguide with a width of 450nm, a multi-mode ridge waveguide with a width of 850nm, a gradient ridge waveguide with a width of 450nm to 850nm, a length of 100um and a width of 850nm are produced. It is a graded ridge waveguide with a length of 450nm and a length of 50um, and the outer ridge height of the ridge waveguide is 60nm. Bragg waveguide gratings 6 are etched on one side of the bus multimode waveguide 3 and the drop single-mode waveguide 8 , the rectangular grating teeth are 100nm and 50nm respectively, and the period of the grating is 344nm.

[0033] The grating period...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com