Huperzine-a lipid micro-sphere preparation

A technology of huperzine A lipid and huperzine A, which is applied in the field of medicine, can solve problems such as difficult dissolution of huperzine A water, achieve the goal of no toxic side effects, reduce irritation and side effects, and improve cognitive function Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

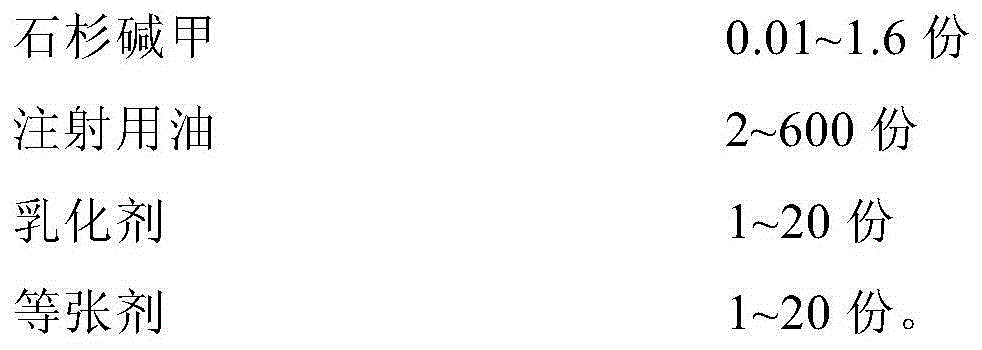

[0031] Example 1 : Huperzine A lipid microsphere preparation, including:

[0032]

[0033]

[0034] The preparation method of huperzine methyl lipid microsphere preparation:

[0035] (1) Preparation of the oil phase: Take 1g of hydrogenated egg yolk lecithin, add ethanol to dissolve it, add huperzine A and stir to dissolve it, evaporate the ethanol under reduced pressure, then add the remaining hydrogenated egg yolk lecithin and acetylated monoglyceride 1. Soybean oil, in a water bath at 70-80°C, stirring to make it dissolve, to obtain the oil phase;

[0036] (2) Preparation of the water phase: adding glycerin to water, stirring to dissolve it, and heating to 70-80°C to obtain the water phase;

[0037] (3) Preparation of colostrum: Add the oil phase in step (1) to the water phase in step (2), at a temperature of 70-80°C, disperse through high-speed shearing, the shearing speed is 2000rpm, and the time is 120 minutes. get colostrum;

[0038] (4) The colostrum is rapid...

Embodiment 2

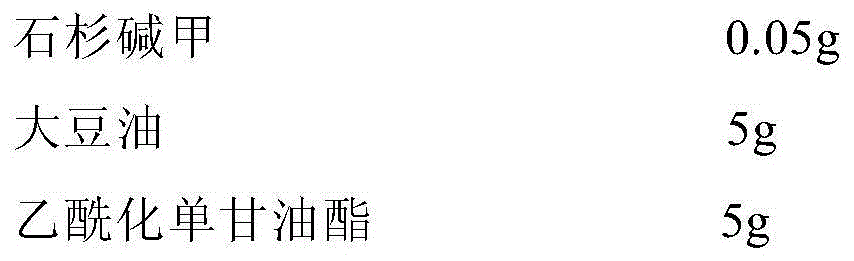

[0040] Example 2 : Huperzine A lipid microsphere preparation, including:

[0041]

[0042] The preparation method of huperzine methyl lipid microsphere preparation:

[0043] (1) Preparation of the oil phase: Take 0.5 g of soybean lecithin, add ethanol to dissolve it, add huperzine A and stir to dissolve it, evaporate the ethanol with nitrogen while stirring, then add the remaining soybean lecithin, soybean oil, acetyl Melt monoglyceride, bath in 70-80°C water, stir to dissolve, and obtain oil phase;

[0044] (2) Preparation of the water phase: adding trehalose into water, stirring to dissolve it, and heating to 70-80°C to obtain the water phase;

[0045] (3) Preparation of colostrum: Add the oil phase in step (1) to the water phase in step (2), at a temperature of 70-80°C, disperse through high-speed shearing, the shearing speed is 10000rpm, and the time is 120 minutes. get colostrum;

[0046](4) The colostrum is rapidly cooled to 15-40°C, homogenized by a high-pressur...

Embodiment 3

[0048] Example 3 : Huperzine A lipid microsphere preparation, including:

[0049]

[0050] The preparation method of huperzine methyl lipid microsphere preparation:

[0051] (1) Preparation of the oil phase: take 10 g of hydrogenated egg yolk lecithin, add ethanol to dissolve it, add huperzine A and stir to dissolve it, evaporate the ethanol with nitrogen while stirring, then add soybean lecithin, corn oil, acetylated mono Glyceride, in a water bath at 70-80°C, stir to dissolve to obtain an oil phase;

[0052] (2) Preparation of the water phase: adding sorbitol into water, stirring to dissolve it, and heating to 70-80°C to obtain the water phase;

[0053] (3) Preparation of colostrum: Add the oil phase in step (1) to the water phase in step (2), at a temperature of 70-80°C, disperse through high-speed shearing, the shearing speed is 5000rpm, and the time is 60 minutes. get colostrum;

[0054] (4) The colostrum is rapidly cooled to 15-40°C, homogenized by a high-pressur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com