Bis(methylsiloxy)ferrocene tricarbon ester monomer and preparation method thereof

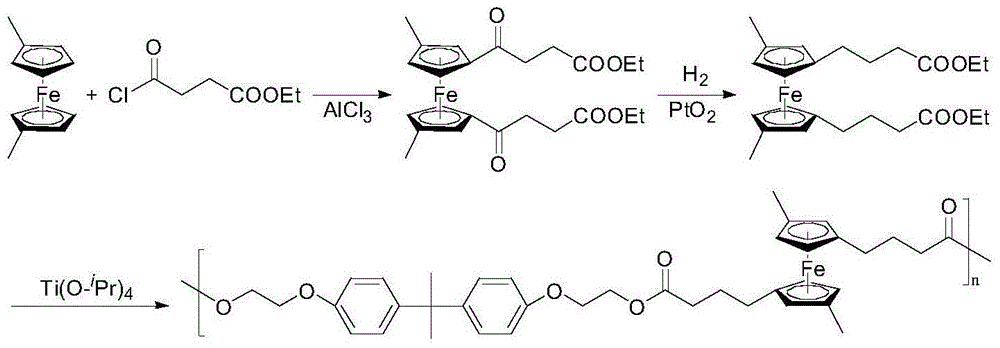

A technology of bismethylsiloxytricarbonate ferrocene and siloxytricarbonate ferrocene is applied in the field of preparation of bismethylsiloxytricarbonate ferrocene monomer, which can solve the problem of expensive raw materials , Harsh preparation conditions, limited sources of raw materials, etc., to achieve the effect of wide source of raw materials, simple and easy preparation, and low price of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

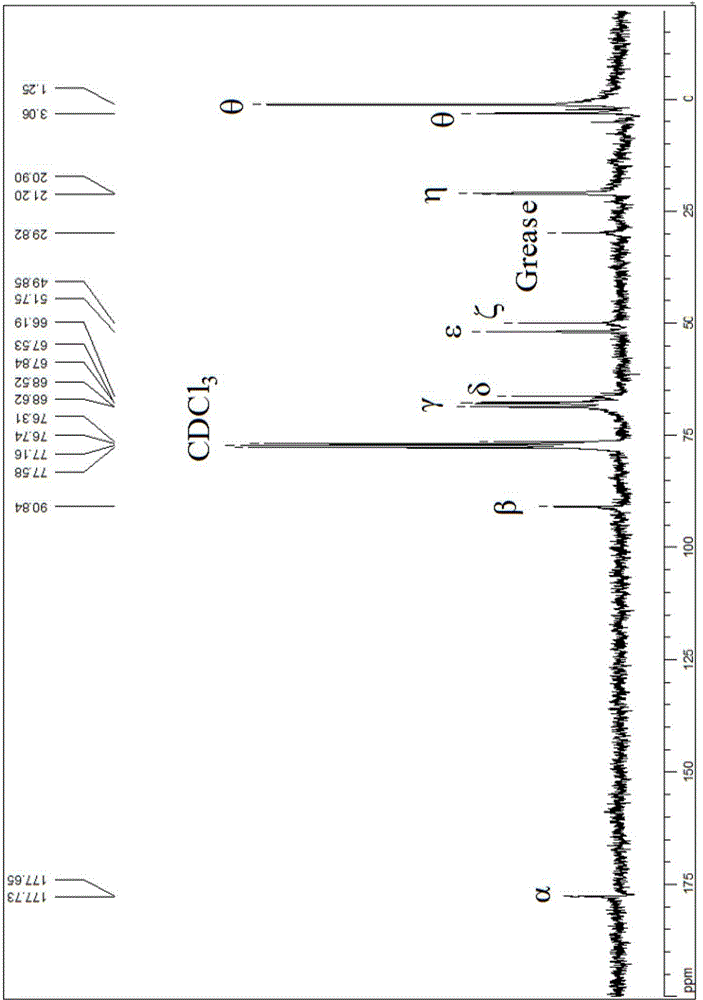

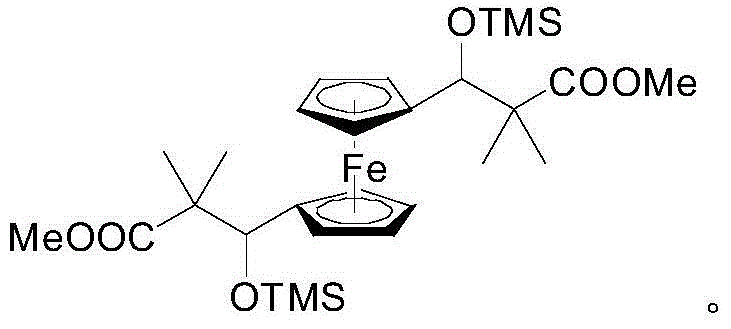

[0024] Dissolve 6.684 g of dialdehyde ferrocene (27.6 mmol) and 11.8 mL of 1-methoxy-1-(trimethylsilyloxy)-2-methyl-1-propene (55.3 mmol) in 100.0 mL of anhydrous dichloromethane ) in the dry Schlenk bottle of 250mL, under the protection of dry nitrogen, quickly drop 0.768g MgI 2 (2.8mmol) in 50.0mL ether solution, after stirring at room temperature for 6.0 hours, 10.0mL saturated NaHCO was added dropwise 3 Quenched, separated to obtain the bottom organic layer, removed the volatile solvent and dried in vacuo, further used 200 mesh to 300 mesh silica gel as the carrier, and used petroleum ether and ethyl acetate as the eluent to obtain the first fraction 5.929g 1 , 1'-bis(2-methoxycarbonyl-2-methyl-1-trimethylsilyloxy-propyl)ferrocene, the yield was 38.3%. Its chemical structure is:

[0025]

[0026] see attached figure 1 , which are respectively the compound (1,1'-bis(2-methoxycarbonyl-2-methyl-1-trimethylsilyloxy-propyl)ferrocene) prepared in this example 13 C NMR ...

Embodiment 2

[0029] Dissolve 6.873 g of dialdehyde ferrocene (28.4 mmol) and 18.2 mL of 1-methoxy-1-(trimethylsilyloxy)-2-methyl-1-propene (85.2 mmol) in 100.0 mL of anhydrous dichloromethane ) in the dry Schlenk bottle of 250mL, under the protection of dry nitrogen, add 1.580g MgI dropwise rapidly 2 (5.7mmol) in 50.0mL ether solution, after stirring at room temperature for 6.0 hours, 10.0mL saturated NaHCO was added dropwise 3 Quenched, separated to obtain the bottom organic layer, removed the volatile solvent and dried in vacuum, further used 200-300-mesh silica gel as a carrier, and used petroleum ether and ethyl acetate as eluents for gradient elution to obtain the first fraction 7.060g 1 , 1'-bis(2-methoxycarbonyl-2-methyl-1-trimethylsilyloxy-propyl)ferrocene, the yield was 42.1%.

[0030] Compound (1,1'-bis(2-methoxycarbonyl-2-methyl-1-trimethylsilyloxy-propyl)ferrocene) prepared in this example 1 H NMR spectrum (400MHz, CDCl 3 ,ppm) and 13 C NMR spectrum (300MHz, CDCl 3 , ppm) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com