Gastrodin nasal starch microspheres with bioadhesive properties and preparation method thereof

A technology of starch microspheres and bioadhesion, applied in the direction of medical preparations containing active ingredients, organic active ingredients, drug combinations, etc., can solve the problems of increasing patient pain, large dosage, low drug concentration, etc., and achieve local safety Good sex, high drug loading, less adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

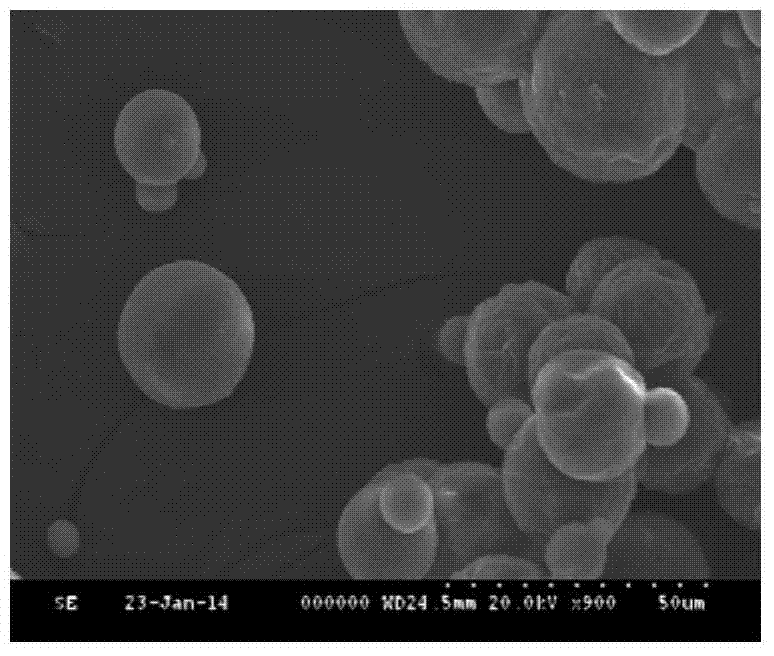

Embodiment 1

[0033] (1) Preparation of the water phase: Weigh 4.5 g of starch, dissolve it in 10 mL of 0.1 g / mL sodium hydroxide aqueous solution, prepare a starch solution with a starch concentration of 45 wt%, and let it stand for 30 minutes to remove air bubbles to obtain the water phase.

[0034] (2) Preparation of the oil phase: Weigh 2.0 g of gastrodin and disperse it in 1 mL of ethyl acetate to obtain the oil phase.

[0035] (3) Preparation of O / W colostrum: slowly add the oil phase into the water phase at room temperature, and stir in the same direction at a speed of 1000 rpm to obtain 9.0 mL of O / W colostrum.

[0036] (4) Preparation of microspheres: preheat 100mL liquid paraffin containing 3.5g Span80 to 40°C, add the above-mentioned colostrum into it, and stir and emulsify in the same direction at 1000rpm for 20min; then add the crosslinking agent epichlorohydrin (ECH) 5.1mL, after cross-linking at 40°C for 4h, centrifuge, pour off the upper oil phase; ) washing, drying under r...

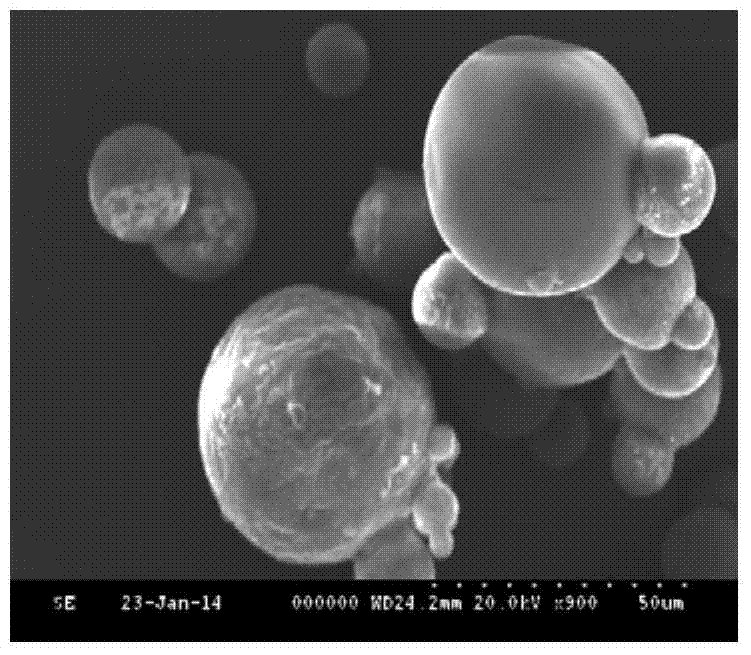

Embodiment 2

[0043] (1) Preparation of the water phase: Weigh 3.0 g of starch, dissolve it in 10 mL of 0.05 g / mL sodium hydroxide aqueous solution, prepare a starch solution with a starch concentration of 30 wt%, and let it stand for 30 minutes to remove air bubbles to obtain the water phase.

[0044] (2) Preparation of the oil phase: weigh 2.0 g of gastrodin and disperse it in 0.8 mL of ethyl acetate to obtain the oil phase.

[0045] (3) Preparation of O / W colostrum: slowly add the oil phase into the water phase at room temperature, and stir in the same direction at a speed of 800 rpm to obtain 10.0 mL of O / W colostrum.

[0046] (4) Preparation of microspheres: Preheat 80 mL of liquid paraffin containing 2.8 g of Span80 to 40 °C, add the above-mentioned colostrum into it, and stir and emulsify in the same direction at a speed of 1400 rpm for 30 min, then add the cross-linking agent epichlorohydrin (ECH) 3mL, after cross-linking at 40°C for 4h, centrifuge and pour off the upper oil phase, ...

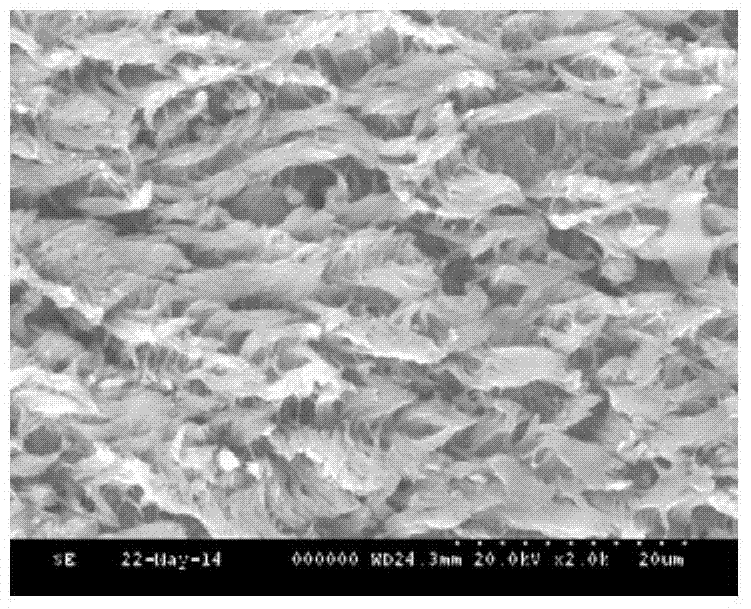

Embodiment 3

[0053] (1) Preparation of the water phase: Weigh 30 g of starch, dissolve it in 100 mL of 0.1 g / mL sodium hydroxide aqueous solution, prepare a starch solution with a starch concentration of 30 wt%, and let it stand for 30 minutes to remove air bubbles to obtain the water phase.

[0054] (2) Preparation of the oil phase: Weigh 30 g of gastrodin and disperse it in 15 mL of ethyl acetate to obtain the oil phase.

[0055] (3) Preparation of O / W colostrum: slowly add the oil phase into the water phase at room temperature, and stir in the same direction at a speed of 1200 rpm to obtain 100 mL of O / W colostrum.

[0056] (4) Preparation of microspheres: Preheat 1000mL liquid paraffin containing 20.0g Span80 to 40°C, add the above-mentioned colostrum into it and stir and emulsify in the same direction at a rate of 1400rpm for 40min, then add the crosslinking agent epichlorohydrin ( ECH) 51mL, after cross-linking at 40°C for 3h, centrifuge, pour off the upper oil phase, and wash the lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com