Solid-phase synthesis method of ziconotide by segment process

A technology of ziconotide and solid-phase synthesis, which is applied in the preparation methods of peptides, chemical instruments and methods, peptides, etc., can solve the problems of long synthesis cycle, many intermediate steps, complicated operations, etc., and is beneficial to industrial large-scale production. , the effect of shortening the synthesis cycle and reducing the difficulty of purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

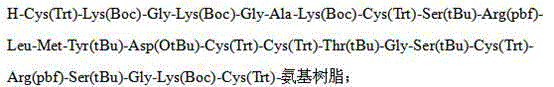

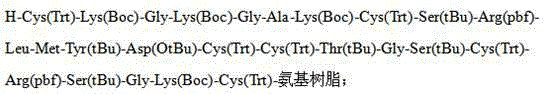

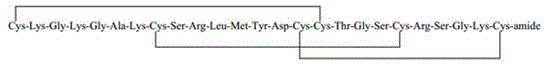

Image

Examples

Embodiment 1

[0068] Example 1: Synthesis of Fmoc-Cys(Trt)-Rink Amide Resins

[0069] Accurately weigh 20.0g of Rink Amide resin (sub=0.33mmol / g) into a synthesis column, wash twice with 160mL DMF, add 160mL DCM to swell for 30min, filter out DCM, wash twice with 160mL DMF; add 20 %piperidine / DMF solution 160ml deprotected twice, reacted for 10min and 15min respectively; then washed twice with 100ml DMF, DCM, DMF respectively; filtered off DMF, added Fmoc-Cys(Trt)-OH / DIC / HOBT Mix the DMF solution [weigh 7.73g (13.2mmol) Fmoc-Cys(Trt)-OH and 1.96g (14.52mmol) HOBT in a conical flask, add 100mL DMF solution and stir to dissolve, add 2.25 ml (14.52mmol) DIC, activated for 3min]; react for 2h, remove the reaction liquid, wash twice with 160mL DMF, add 120mL end-capping reagent (24ml acetic anhydride, 20.4ml pyridine, 75.6mL DCM) to react for 2h, filter off with suction The reaction solution was washed 3 times with DMF, DCM and methanol respectively, and after vacuum drying, 22.06g of Fmoc-Cys...

Embodiment 2

[0070] Example 2: Synthesis of Fmoc-Cys(Trt)-Rink Amide-AM Resins

[0071] Accurately weigh 20.0g of Rink Amide-AM resin (sub=0.32mmol / g) into the synthesis column, wash twice with 160mL DMF, add 160mL DCM to swell for 30min, filter out the DCM, and wash twice with 160mL DMF; Add 160ml of 20% piperidine / DMF solution for deprotection twice, react for 10min and 15min respectively; then wash twice with 100ml DMF, DCM, DMF respectively; filter off DMF, add Fmoc-Cys(Trt)-OH / DIC / Mixed DMF solution of HOBT [weigh 3.75g (6.4mmol) Fmoc-Cys(Trt)-OH and 0.95g (7.04mmol) HOBT in a conical flask, add 100mL DMF solution and stir to dissolve, at low temperature (0°C) Add 1.09ml (7.04mmol) DIC, activate for 3min]; react for 2h, remove the reaction solution, wash twice with 160mL DMF, add 120mL end-capping reagent (24ml acetic anhydride, 20.4ml pyridine, 75.6mL DCM) to react for 2h, pump out The reaction solution was filtered off, washed three times with DMF, DCM, and methanol, and dried i...

Embodiment 3

[0072] Example 3: Synthesis of Fmoc-Gly-CTC Resins

[0073] Weigh 70.0g (sub=1.00mmol / g) of CTC resin and place it in a synthesis column, wash twice with 420mL DMF, add 420mL DCM to swell for 30min; after filtering off DCM, add 41.62g of Fmoc-Gly-OH DCM solution 250ml, add DIPEA 25.45ml at low temperature (0°C), react for 60min, remove the reaction solution, add DCM / CH 3 420ml of OH / DIPEA (volume ratio 17:2:1) mixed solution was capped for 30min; then washed 3 times with DMF, DCM, and methanol respectively, and vacuum-dried to obtain 86.50g of Fmoc-Gly-CTC Resins; the degree of substitution was 0.80mmol / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com