Method for extracting manganese from composite manganese ore composed of multiple phases containing manganese

A composite manganese ore and multi-phase technology, applied in the direction of photography technology, equipment, photography auxiliary technology, etc., can solve the problems of no scientific and reasonable development of new manganese ore resources, no research on manganese ore resources, multi-component components, etc., to achieve power Low consumption, reduced energy consumption, and high reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

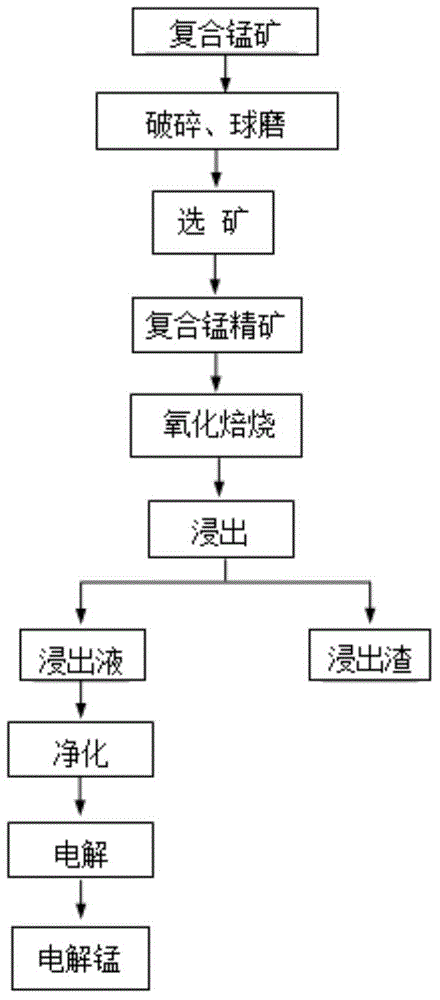

[0045] like figure 1 As shown, a kind of method for extracting manganese from the composite manganese ore of manganese-containing multi-phase composition, its steps are:

[0046] (1) Dry the composite manganese ore composed of manganese-containing multi-phase composition, and then, after crushing and ball milling, obtain composite mineral material less than 150 meshes, and adopt magnetic separation method to beneficiate the composite manganese concentrate to obtain composite manganese concentrate.

[0047] (2) adding the composite manganese concentrate of manganese-containing multi-phase composition into the dense moving bed, the dense moving bed is equipped with a temperature control system, a gas flow control system and a waste gas absorption system, and in the dense moving bed The direction of the gas flow in the interior is reversed to the direction of the material movement, and then the oxygen-enriched air with a pressure of 0.12Mpa is introduced into the dense moving be...

Embodiment 2

[0052] like figure 1 As shown, a kind of method for extracting manganese from the composite manganese ore of manganese-containing multi-phase composition, its steps are:

[0053] (1) Dry the composite manganese ore containing manganese multi-phase composition, and then, after crushing and ball milling, obtain composite mineral material less than 150 meshes, and adopt magnetic separation method to beneficiate the ore to obtain composite manganese concentrate.

[0054] (2) adding the composite manganese concentrate of manganese-containing multi-phase composition into the dense moving bed, the dense moving bed is equipped with a temperature control system, a gas flow control system and a waste gas absorption system, and in the dense moving bed The direction of the gas flow inside is opposite to the direction of the material movement, and then the pressure is 0.11Mpa oxygen-enriched air into the dense moving bed, and the constant temperature oxidation roasting is carried out at a...

Embodiment 3

[0059] like figure 1 As shown, a kind of method for extracting manganese from the composite manganese ore of manganese-containing multi-phase composition, its steps are:

[0060] (1) Dry the composite manganese ore composed of manganese-containing multi-phase composition, and then, after crushing and ball milling, obtain composite mineral material less than 150 meshes, and adopt magnetic separation method to beneficiate the composite manganese concentrate to obtain composite manganese concentrate.

[0061] (2) adding the composite manganese concentrate of manganese-containing multi-phase composition into the dense moving bed, the dense moving bed is equipped with a temperature control system, a gas flow control system and a waste gas absorption system, and in the dense moving bed The direction of the gas flow in the interior is reversed to the direction of the material movement, and then the oxygen-enriched air with a pressure of 0.11Mpa is introduced into the dense moving be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com