Device and method for producing silane by disproportionated reaction distillation of trichlorosilane

A technology of trichlorosilane and disproportionation reaction, applied in the direction of silicon hydride, etc., can solve the problems of high operating pressure of silane purification tower, high cost of condensing refrigerant at the top of the tower, and difficult process realization, so as to save high-quality cooling capacity and increase operation The effect of pressure, reducing equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

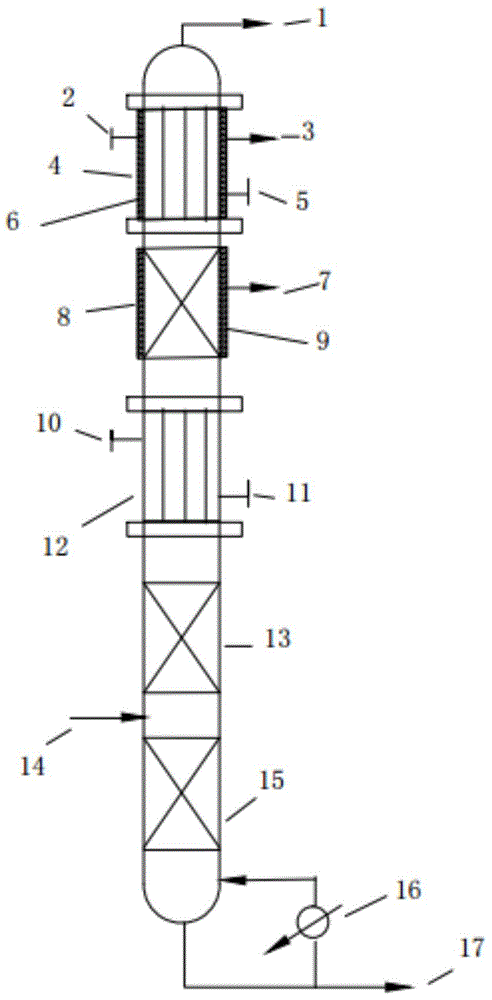

[0040] The TCS raw material is pumped into the disproportionation reaction rectification tower, and the middle part of the tower is filled with two sections of catalyst with a total structure of 8m. The catalyst is A21, which is made of basic anion exchange resin packed in a corrosion-resistant cloth bag, and the wire mesh corrugated packing is spaced into rolls. It plays the role of reactive distillation, and the number of plates in the column rectification section and stripping section is 10. The temperature at the top of the control tower is between -40°C, and circulating water is used to condense in the tower, and the temperature in the control tower is about 0°C. The operating pressure of the disproportionation reaction distillation tower is controlled at 500Kpa, the temperature of the tower bottom is about 110°C, the temperature of the middle reaction section increases gradually from top to bottom, and the temperature of the reaction section is controlled between 50-100°C...

example 2

[0042] The TCS raw material is pumped into the disproportionation reaction rectification tower, and the middle part of the tower is filled with a catalyst with a total structure of 8m in two sections. The catalyst is A100, which is made of basic anion exchange resin packed in a corrosion-resistant cloth bag, and is rolled into a roll with a wire mesh corrugated packing. It plays the role of reactive distillation, and the number of plates in the column rectification section and stripping section is 10. The temperature at the top of the control tower is between -40°C, and circulating water is used to condense in the tower, and the temperature in the control tower is about 0°C. The operating pressure of the disproportionation reaction distillation tower is controlled at 500Kpa, the temperature of the tower bottom is about 110°C, the temperature of the middle reaction section increases gradually from top to bottom, and the temperature of the reaction section is controlled between 5...

example 3

[0044] The TCS raw material is pumped into the disproportionation reaction rectification tower, and the middle part of the tower is filled with two sections of catalyst with a total structure of 8m. The catalyst is A21, which is made of basic anion exchange resin packed in a corrosion-resistant cloth bag, and the wire mesh corrugated packing is spaced into rolls. It plays the role of reactive distillation, and the number of plates in the column rectification section and stripping section is 100. The temperature at the top of the control tower is between -40°C, and circulating water is used to condense in the tower, and the temperature in the control tower is about 0°C. The operating pressure of the disproportionation reaction distillation tower is controlled at 500Kpa, the temperature of the tower bottom is about 110°C, the temperature of the middle reaction section increases gradually from top to bottom, and the temperature of the reaction section is controlled between 50-100°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com