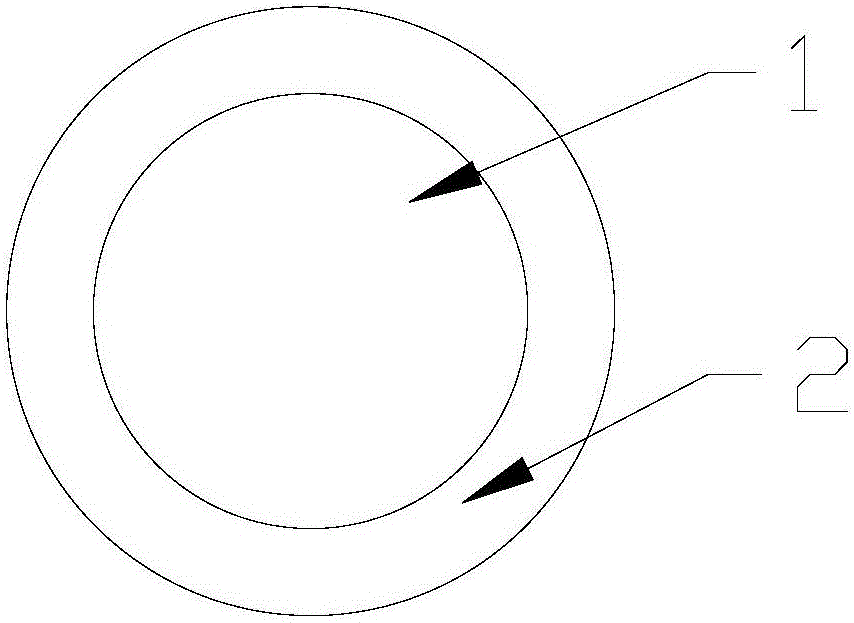

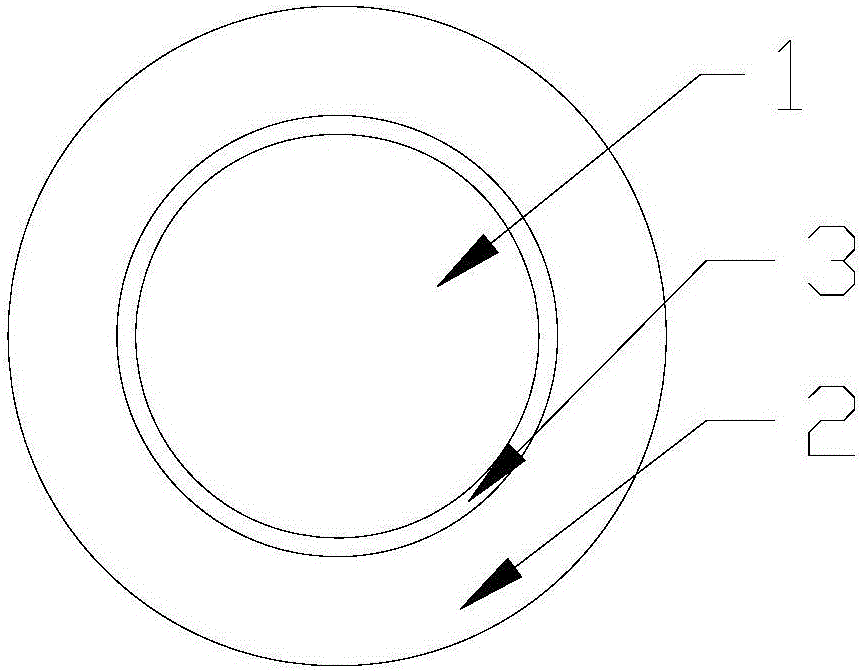

Aerial insulated cable cross linked polyethylene insulation material containing graphene and cable

An overhead insulated cable and cross-linked polyethylene technology, which is applied in the direction of insulated cables, power cables with shielding layers/conductive layers, insulated conductors, etc., can solve problems such as poor heat dissipation, low thermal conductivity, and increased transmission power loss. Achieve the effect of improving service life, good heat dissipation, and improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1, Cross-linked polyethylene insulation material for overhead insulated cables containing graphene, consisting of the following parts by mass: 80 parts of low-density polyethylene, 20 parts of linear low-density polyethylene, and the thermal conductive agent graphene 0.05, auxiliary Thermal conductive agent aluminum nitride 5 parts, silane coupling agent vinyl trimethoxysilane 0.5 part, antioxidant 1010 0.2 part, antioxidant 300# 0.01 part, plasticizer dibutyl tin dilaurate 0.03 part, initiator DCP 0.03 parts.

Embodiment 2

[0044] Example 2, Cross-linked polyethylene insulation material for overhead insulated cables containing graphene, composed of the following parts by mass: 90 parts of low-density polyethylene, 10 parts of linear low-density polyethylene, and 3.5 of graphene oxide as the thermal conductive agent. Auxiliary heat transfer agent 1 part aluminum nitride, 3 parts silane coupling agent vinyl trimethoxysilane, 0.1 part antioxidant 1010, 0.01 part antioxidant 300#, plasticizer 0.15 part dibutyl tin dilaurate, initiator 0.15 copies of DCP.

Embodiment 3

[0045] Example 3, cross-linked polyethylene insulation material for overhead insulated cables containing graphene, consisting of the following parts by mass: 85 parts of low-density polyethylene, 15 parts of linear low-density polyethylene, 0.5 of the thermal conductive agent graphene, auxiliary Thermal conductive agent 3 parts aluminum nitride, silane coupling agent vinyl trimethoxy silane 1 part, antioxidant 1010 0.1 part, antioxidant 300# 0.01 part, plasticizer dibutyl tin dilaurate 0.1 part, initiator DCP 0.1 part.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com