Moisturizer suitable for being used on oily skin and preparation method thereof

A technology of oily skin and moisturizing cream, applied in the field of skin care products, can solve the problems of strong irritation, difficulty in fat-soluble salicylic acid, and impact on safety, and achieve strong adsorption, fine and stable paste, and good oil control effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

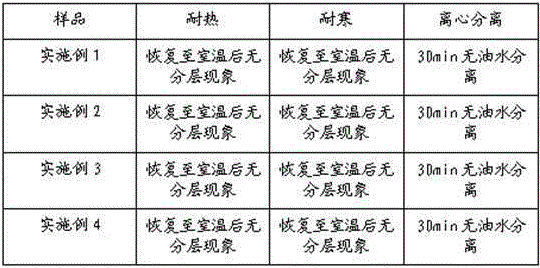

Examples

Embodiment 1

[0019] (1) Product formula (based on 100 parts by total weight of components)

[0020] 5 parts of isooctyl palmitate, 2 parts of polydimethylsiloxane, 5 parts of squalane, 1 part of cetearyl alcohol, 2 parts of fatty alcohol polyoxyethylene ether, 1.5 parts of glyceryl monostearate, 3 parts of glycerin, 1 part of sodium carboxymethyl starch, 2 parts of Vivapur CS 9 FM natural lignocellulose powder, 0.2 part of methylparaben, 0.1 part of propylparaben, 0.15 part of rose essence, and the balance of deionized water.

[0021] (2) Preparation process

[0022] Mix isooctyl palmitate, polydimethylsiloxane, squalane, cetearyl alcohol, fatty alcohol polyoxyethylene ether, and glyceryl monostearate evenly, and heat to 75°C to form an oil phase; Mix glycerin, sodium carboxymethyl starch, Vivapur CS 9 FM natural lignocellulose powder, and deionized water evenly, and heat to 75°C to make a water phase; add the oil phase and water phase to a vacuum homogenizer for homogeneous emuls...

Embodiment 2

[0024] (1) Product formula (based on 100 parts by total weight of components)

[0025] 10 parts of isooctyl palmitate, 5 parts of polydimethylsiloxane, 15 parts of squalane, 3 parts of cetearyl alcohol, 4 parts of fatty alcohol polyoxyethylene ether, 3 parts of glyceryl monostearate, 2 parts of glycerin, 2 parts of sodium carboxymethyl starch, 2 parts of Vitacel CS 20 FC natural lignocellulose powder, 0.2 part of methylisothiazolinone, 0.1 part of propylparaben, 0.15 part of lily essence, and the balance of deionized water .

[0026] (2) Preparation process

[0027] Mix isooctyl palmitate, polydimethylsiloxane, squalane, cetearyl alcohol, fatty alcohol polyoxyethylene ether, and glyceryl monostearate evenly, and heat to 75°C to form an oil phase; Mix glycerin, sodium carboxymethyl starch, Vitacel CS 20 FC natural lignocellulose powder, and deionized water evenly, and heat to 75°C to make a water phase; add the oil phase and water phase to a vacuum homogenizer for hom...

Embodiment 3

[0029] (1) Product formula (based on 100 parts by total weight of components)

[0030] 4 parts of isooctyl palmitate, 1 part of polydimethylsiloxane, 5 parts of squalane, 2 parts of cetearyl alcohol, 2 parts of fatty alcohol polyoxyethylene ether, 1 part of glyceryl monostearate, 3 parts of glycerin, 0.2 parts of carbomer, 1 part of Vivapur CS 70 FM natural lignocellulose powder, 0.3 parts of triethanolamine, 0.2 parts of methylisothiazolinone, 0.2 parts of methylparaben, 0.15 parts of rose essence, deionized water balance.

[0031] (2) Preparation process

[0032] Mix isooctyl palmitate, polydimethylsiloxane, squalane, cetearyl alcohol, fatty alcohol polyoxyethylene ether, and glyceryl monostearate evenly, and heat to 75°C to form an oil phase; Mix glycerin, carbomer, Vivapur CS 70 FM natural lignocellulose powder, triethanolamine, and deionized water evenly, and heat to 80°C to make a water phase; add the oil phase and water phase to a vacuum homogenizer and homog...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com