A kind of nano cartilage repair material with oriented nanofiber mat as skeleton and preparation method thereof

A nanofiber and cartilage repair technology, applied in medical science, prosthesis, etc., can solve the problems of poor mechanical properties of natural biomaterials, rapid degradation and absorption, and difficulty in mass production, and achieve good biocompatibility and Bioactivity, good biocompatibility, and good biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A preparation method of a nano-cartilage repair material with an oriented nano-fiber mat as a skeleton, the steps are as follows:

[0026] (1) Ultrasonic disperse graphene into hexafluoroisopropanol solution, then put silk fibroin and stir at room temperature for 48 hours to obtain a silk fibroin solution with a silk mass concentration of 20%, put hyaluronic acid into formic acid solution and stir at room temperature 48h, to obtain a hyaluronic acid solution with a mass concentration of 0.5%, pour the mixed solution of silk fibroin and graphene into the hyaluronic acid solution and stir for 24h at room temperature to obtain a spinning solution of silk fibroin / hyaluronic acid / graphene;

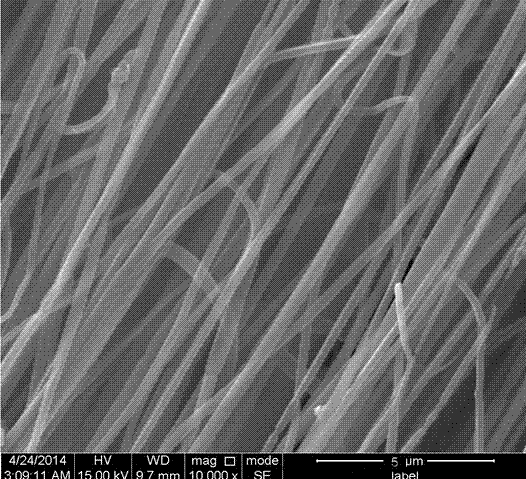

[0027] (2) The silk fibroin / hyaluronic acid / graphene mixed solution obtained in step (1) was electrospun, and the rotating drum was used as a receiving device to obtain an oriented nanofiber mat. The spinning voltage was 18 kV, and the spinning The total flow rate of the solution is 0.58...

Embodiment 2

[0032] A preparation method of a nano-cartilage repair material with an oriented nano-fiber mat as a skeleton, the steps are as follows:

[0033] (1) Ultrasonically disperse graphene into hexafluoroisopropanol solution, then put silk fibroin and stir at room temperature for 24 hours to obtain a silk fibroin solution with a silk mass concentration of 20%, put hyaluronic acid into formic acid solution and stir at room temperature 24h, to obtain a hyaluronic acid solution with a mass concentration of 0.15%, pour the mixed solution of silk fibroin and graphene into the hyaluronic acid solution and stir for 12h at room temperature to obtain a spinning solution of silk fibroin / hyaluronic acid / graphene;

[0034] (2) Electrospinning the silk fibroin / hyaluronic acid / graphene mixed solution obtained in step (1), using a rotating drum as a receiving device to obtain an oriented nanofiber mat. The spinning voltage was 14kV, the total flow rate of the spinning solution was 0.8mL / h, the inn...

Embodiment 3

[0038] A preparation method of a nano-cartilage repair material with an oriented nano-fiber mat as a skeleton, the steps are as follows:

[0039] (1) Ultrasonically disperse graphene into hexafluoroisopropanol solution, then put silk fibroin and stir at room temperature for 30 hours to obtain a silk fibroin solution with a silk mass concentration of 18%, put hyaluronic acid into formic acid solution and stir at room temperature 30h, to obtain a hyaluronic acid solution with a mass concentration of 0.5%, pour the mixed solution of silk fibroin and graphene into the hyaluronic acid solution and stir for 18h at room temperature to obtain a spinning solution of silk fibroin / hyaluronic acid / graphene;

[0040] (2) Electrospinning the silk fibroin / hyaluronic acid / graphene mixed solution obtained in step (1), using a rotating drum as a receiving device to obtain an oriented nanofiber mat. The spinning voltage was 18 kV, the total flow rate of the spinning solution was 0.56mL / h, the in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com