Modified anode material and preparation method thereof as well as lithium ion battery

A positive electrode material and modification technology, applied in the field of modified positive electrode material and its preparation, and lithium ion battery, can solve the problems that need to be further improved, the cycle performance cannot meet the needs of the market, etc., so as to improve the cycle capacity retention ability. , good cycle performance and high temperature storage performance, the effect of reducing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The invention provides a method for preparing a modified positive electrode material, comprising:

[0037] The positive electrode material and the aluminum oxyhydroxide sol are stirred and reacted in water and then evaporated to dryness to obtain a powder product. The positive electrode material is a compound shown in formula I:

[0038] Li n (Ni x co y mn 1-x-y )O 2 Formula I;

[0039] In formula I, 0

[0040] The powder product is calcined to obtain a modified cathode material.

[0041] In the invention, the positive electrode material and the aluminum oxyhydroxide sol are stirred and reacted in water, and then evaporated to dryness to obtain a powder product. In an embodiment of the present invention, the positive electrode material and water can be stirred and mixed to obtain a mixed solution; the mixed solution and the aluminum oxyhydroxide sol are stirred and reacted and then evaporated to dryness to obtain a powder product...

Embodiment 1

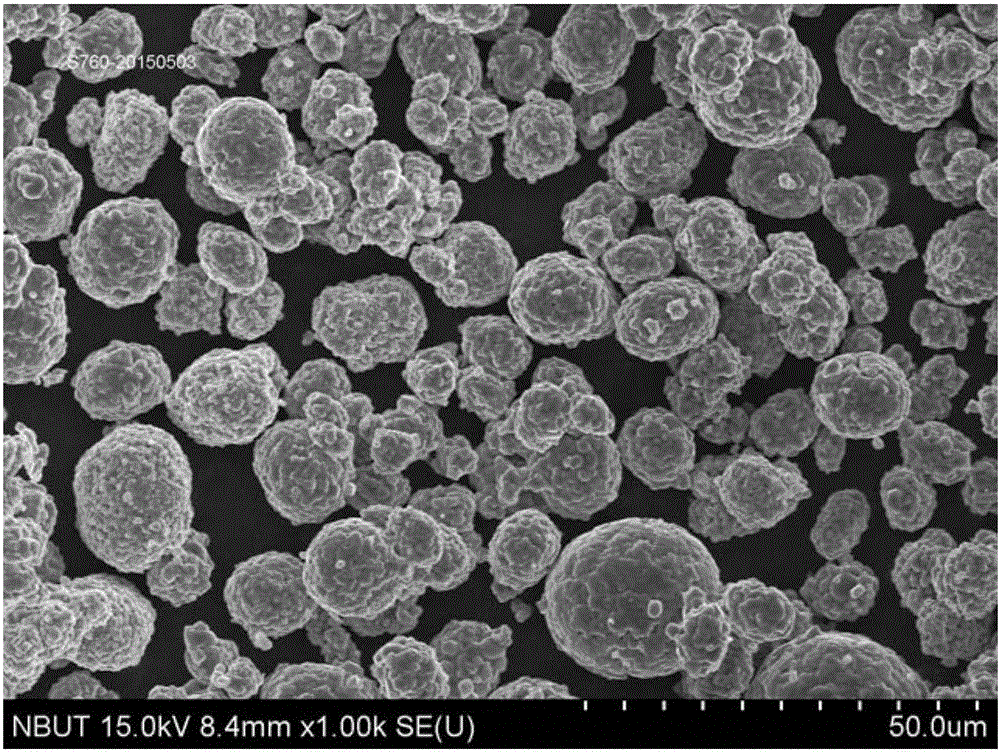

[0082]Adopting nickel sulfate, cobalt sulfate and manganese sulfate as raw materials, respectively preparing nickel sulfate aqueous solution, cobalt sulfate aqueous solution and manganese sulfate salt solution with a concentration of 2mol / L, the described nickel sulfate aqueous solution, cobalt sulfate aqueous solution and manganese sulfate aqueous solution by volume ratio Be mixed with the ratio of 6:2:2, and the total concentration of nickel, cobalt and manganese in the mixed solution is 2mol / L; The aqueous solution is added to the reaction kettle for precipitation at a pH value of 12 and 50°C, and the co-precipitated product is washed and dried to prepare a Ni 0.6 co 0.2 mn 0.2 (OH) 2 the precursor of

[0083] The precursor and lithium carbonate powder are mixed in a molar ratio of 1:1.06; the resulting mixture is sintered at 800°C in an air-atmosphere sintering furnace to obtain a molecular formula of Li 1.06 (Ni 0.6 co 0.2 mn 0.2 )O 2 positive electrode material; ...

Embodiment 2

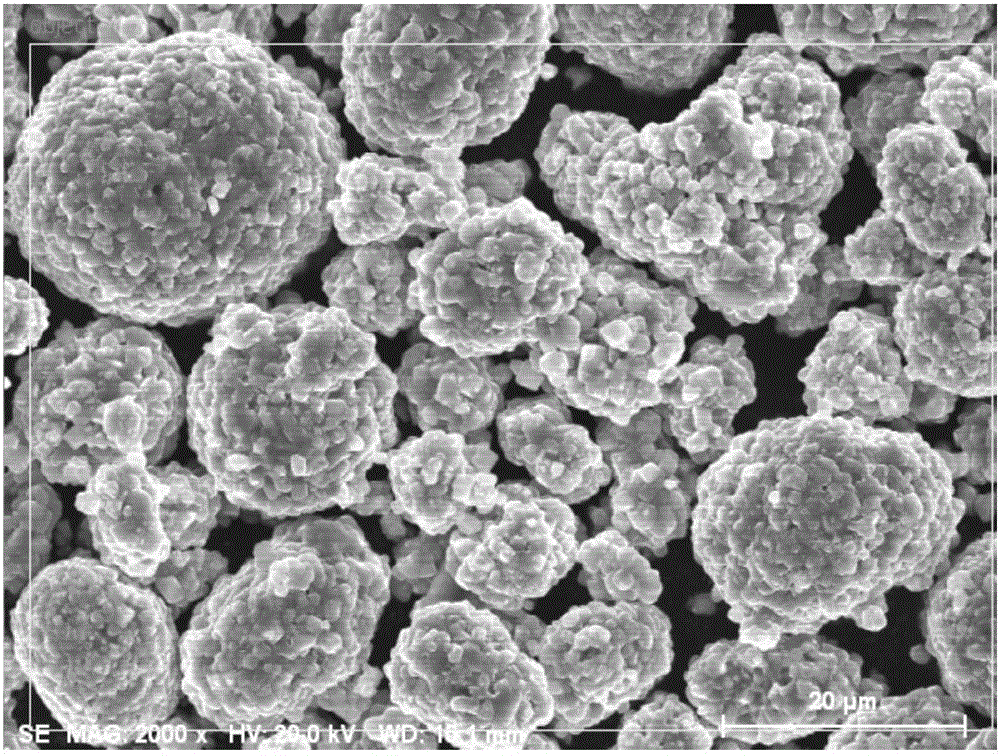

[0089] Prepare positive electrode material according to the method described in Example 1;

[0090] Stirring and mixing the positive electrode material and water for 5 minutes at a mass ratio of 0.5:1 to obtain a dispersion solution; diluting the A-4 type acidic aluminum oxyhydroxide sol with a particle size of 4 nm with water to obtain an aluminum oxyhydroxide sol solution, The mass content of aluminum in the aluminum oxyhydroxide sol solution is 5%; the aluminum oxyhydroxide sol solution is added dropwise to the above dispersion solution at a speed of 50mL / min by a metering pump, and stirred for 10min to obtain The mixed solution was heated and dried under vacuum at 120° C. to obtain a powder product; the powder product was calcined in a sintering furnace at 600° C. for 8 hours to obtain a modified positive electrode material.

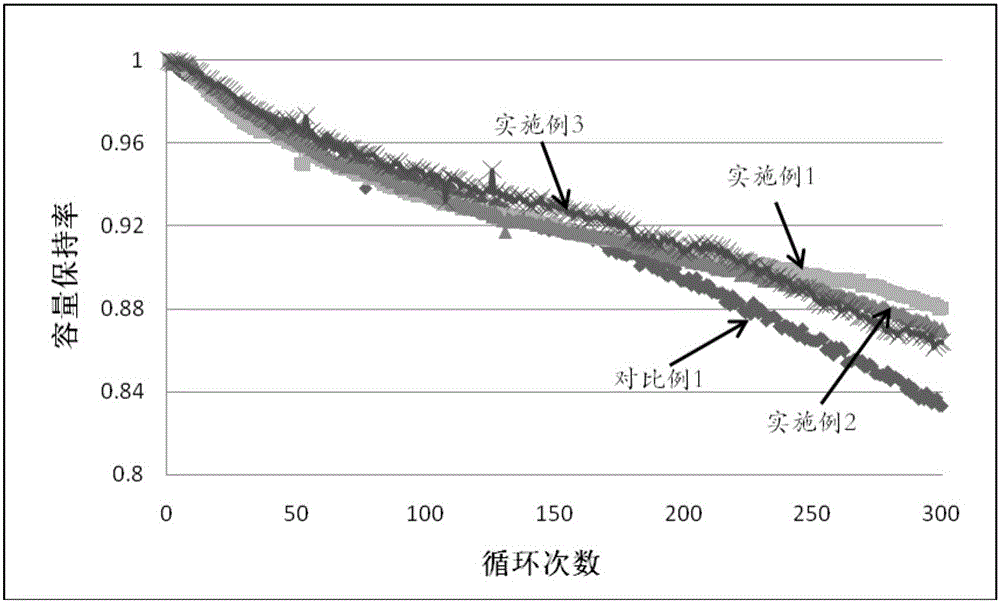

[0091] According to the method described in the above technical solution, the modified positive electrode material prepared in Example 2 of the pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com