Organic solid waste high-temperature carbonization and drying system with waste heat utilization device

A high-temperature carbonization, organic solid technology, applied in the direction of solid waste removal, etc., can solve the problems of the huge area of the solar drying room, the dehydration effect cannot meet the requirements, and the hidden safety hazards, etc., to achieve obvious energy saving effect, avoid odorous gas, The effect of maintaining physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings.

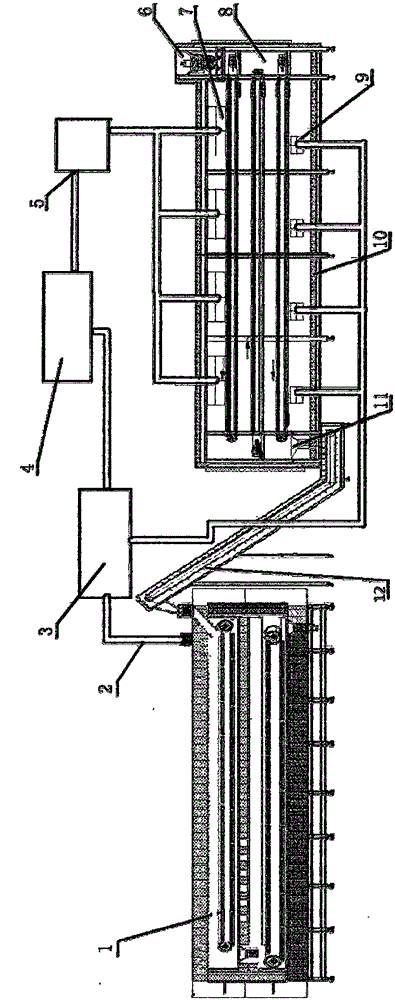

[0011] Such as figure 1 As shown, a high-temperature carbonization and drying system for organic solid waste with a waste heat utilization device includes a carbonization machine 1, a drying machine 2, a heat exchanger 3, a hot air unit 9, a return air unit 7, a dehumidifier 5 and exhaust gas Processing device 4, the carbonization machine 1 is connected to the drying machine 2 through the screw conveyor 12, and the drying machine 2 is provided with a distributor 6 and a screw discharger 11; the hot air unit 9 is installed at the bottom of the drying machine 2 , the return air unit 7 is installed on the top of the drying machine 2, the carbonization machine 1 is connected to the heat exchanger 3 and the hot air unit 9 through the high-temperature gas conduit 2 in turn, and the return air unit 7 is connected to the dehumidifier 5 through the return air duct 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com