Preparation method for fiberboards

A fiberboard and fiber slurry technology, applied in the field of fiberboard, can solve the problems of high cost, secondary pollution, low bonding strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

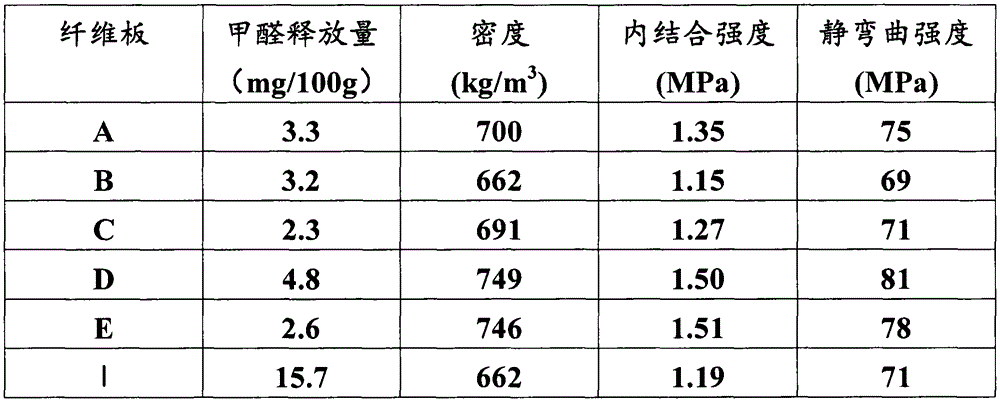

Examples

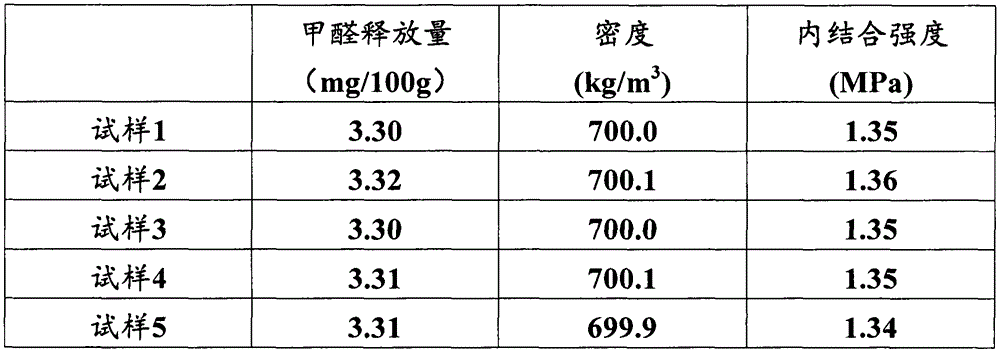

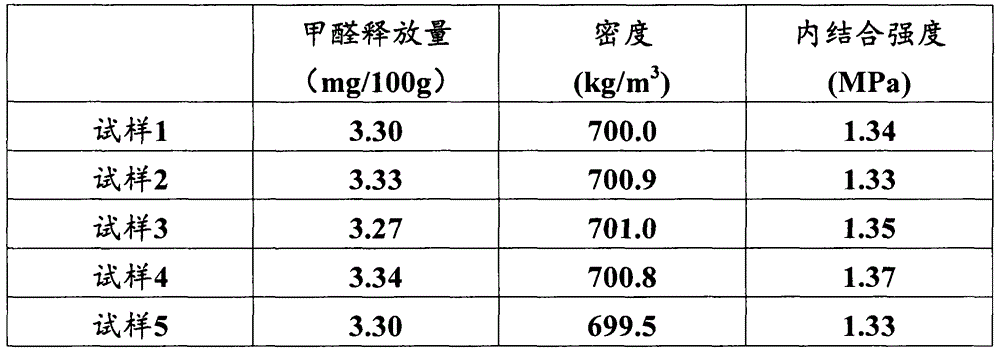

Embodiment 1

[0048] 125 parts by weight of fiber slurry, 10 parts by weight of urea-formaldehyde resin, and 6.5 parts by weight of propyl p-hydroxybenzoate are uniformly mixed in a stirring tank, and the mixture is dried at 50-70° C. until the water content is 15 wt % to obtain a mixture. The mixture was pre-pressed at 4-5MPa for 30s to form a blank, and the blank was isostatically pressed at 8MPa and 70°C for 1min to form a slab. The slab is hot-pressed, and the hot-pressing conditions are as follows: the temperature is 150-160°C; the temperature is raised to 13.5-19MPa within 20-30s, and the pressure is maintained for 60-120s; and then the pressure is reduced to 3.5-5.5MPa within 10-15s. Hold the pressure for 65-135s; then rise to 6-8.5MPa within 10-15s, hold the pressure for 50-75s; finally depressurize evenly to 0MPa within 30-45s. The hot-pressed sheet was cooled to room temperature, tempered and sanded to obtain a fiberboard A with a thickness of 25 mm.

Embodiment 2

[0050] 167 parts by weight of fiber slurry, 20 parts by weight of urea-formaldehyde resin, and 11 parts by weight of propyl p-hydroxybenzoate are uniformly mixed in a stirring tank, and the mixture is dried at 60-70°C until the water content is 10 wt%, to obtain a mixture. The mixture was pre-pressed at 4-5MPa for 40s to form a blank, and the blank was isostatically pressed at 7MPa and 70°C for 50s to form a slab. The slab is hot-pressed, and the hot-pressing conditions are as follows: the temperature is 150-160°C; the temperature is raised to 13.5-19MPa within 20-30s, and the pressure is maintained for 60-120s; and then the pressure is reduced to 3.5-5.5MPa within 10-15s. Hold the pressure for 65-135s; then rise to 6-8.5MPa within 10-15s, hold the pressure for 50-75s; finally depressurize evenly to 0MPa within 30-45s. The hot-pressed sheet was cooled to room temperature, tempered and sanded to obtain a fiberboard B with a thickness of 25 mm.

Embodiment 3

[0052] 140 parts by weight of fiber slurry, 15 parts by weight of modified urea-formaldehyde resin, and 4.5 parts by weight of propyl p-hydroxybenzoate were uniformly mixed in a stirring tank, and the mixture was dried at 80°C until the water content was 10 wt%, to obtain a mixture. The mixture is pre-pressed at 4-5MPa for 1min to form a blank, and the blank is isostatically pressed at 7-8MPa and 60-70°C for 50s to form a slab. The slab is hot-pressed, and the hot-pressing conditions are as follows: the temperature is 150-160°C; the temperature is raised to 13.5-19MPa within 20-30s, and the pressure is maintained for 60-120s; and then the pressure is reduced to 3.5-5.5MPa within 10-15s. Hold the pressure for 65-135s; then rise to 6-8.5MPa within 10-15s, hold the pressure for 50-75s; finally depressurize evenly to 0MPa within 30-45s. The hot-pressed sheet was cooled to normal temperature, tempered and sanded to obtain a fiberboard C with a thickness of 25 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com